We Always Focus On…

VALUE

SERVICES

QUALITY

About RicoCNC…

- RicoCNC was established in 2015, and our products have been exported to over 110 countries. We are a one-stop supplier of CNC industrial products.

- RicoCNC offers a wide range of high-quality and value-priced CNC spare parts and tools for the world marketplace.

- Our engineers and sales professionals have an average of 10 years of experience in the industry, bringing a depth of knowledge that directly benefits our customers.

- The quality of the spindles we supply is initially high. No copy here.

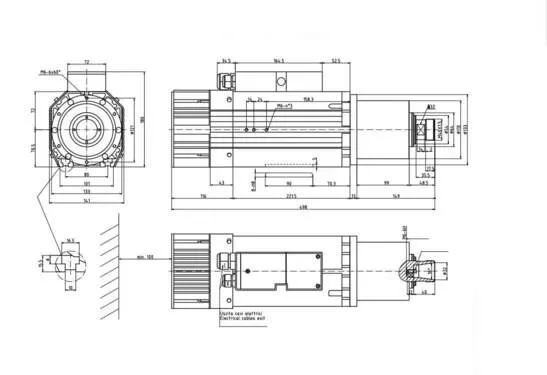

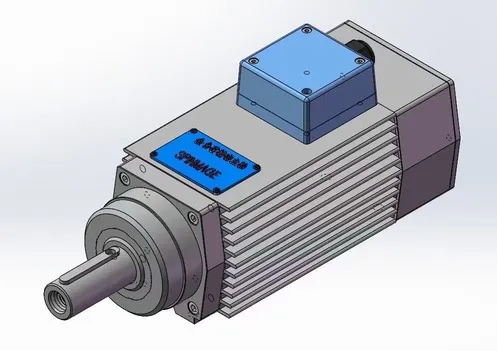

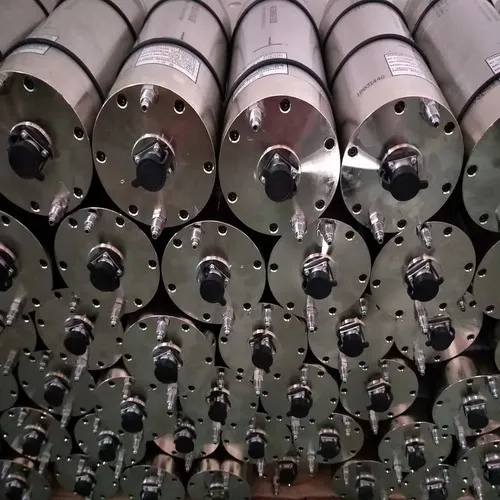

The CNC Spindle Motor Exhibition and Store

It’s Time For You To Upgrade Your CNC Machines…

With the development of technology, the competition in manufacturing has become more complex and more challenging, and staying ahead requires the most advanced production tools. Our new generation of CNC electro spindles, featuring the best technology, is designed to enhance efficiency, reduce costs, and guarantee top-notch product quality. They are the best choice for upgrading your production capabilities.

The Application of The CNC Spindles

Woodworking

Our spindles surpass in wood processing and are adept at traditional craftsmanship and modern innovation. We deliver accurate and efficient machining services from intricate furniture making to complicated wood art designs.

Foam processing

Our electro spindles offer exceptional performance in foam carving, handling large-scale sculptures and delicate decorations. With outstanding craftsmanship and an extreme pursuit of detail, we can turn your creativity into reality.

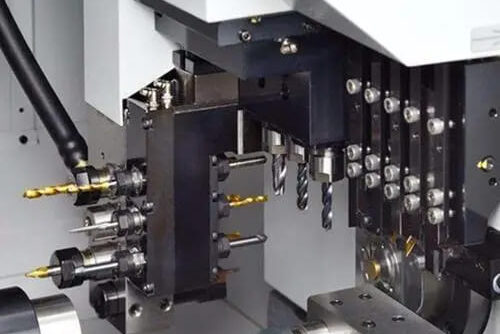

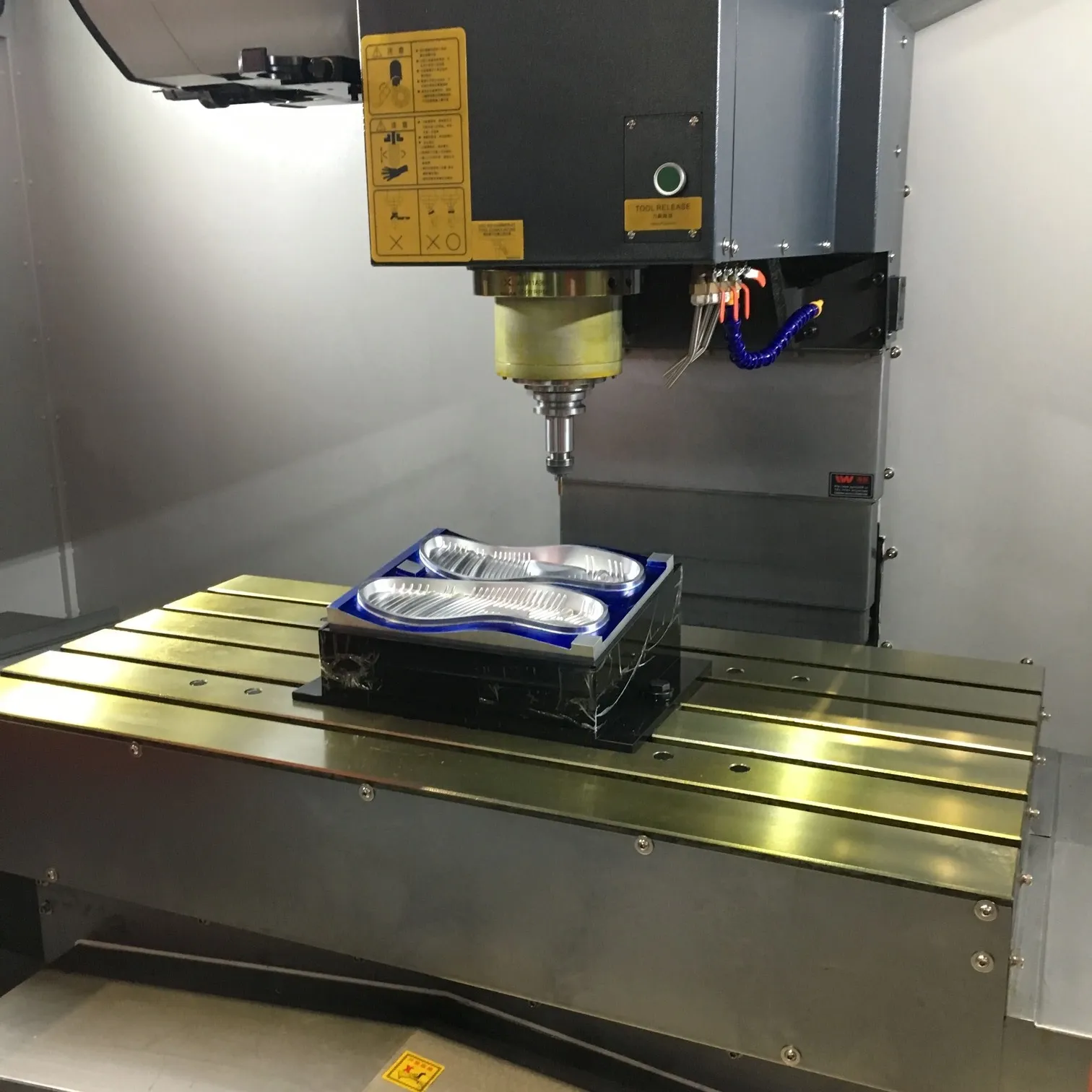

Metal processing

The spindles we offer can handle everything from simple cutting to complex metal structure design. With advanced machining equipment, we ensure that every metal product manufactured with our CNC spindles meets industrial standards.

Stone Processing

The spindles we provide are also top-notch in stone processing efficiency, whether it’s rough cutting or exquisite carving. Our spindles can complete the machining tasks according to your needs or ideas.

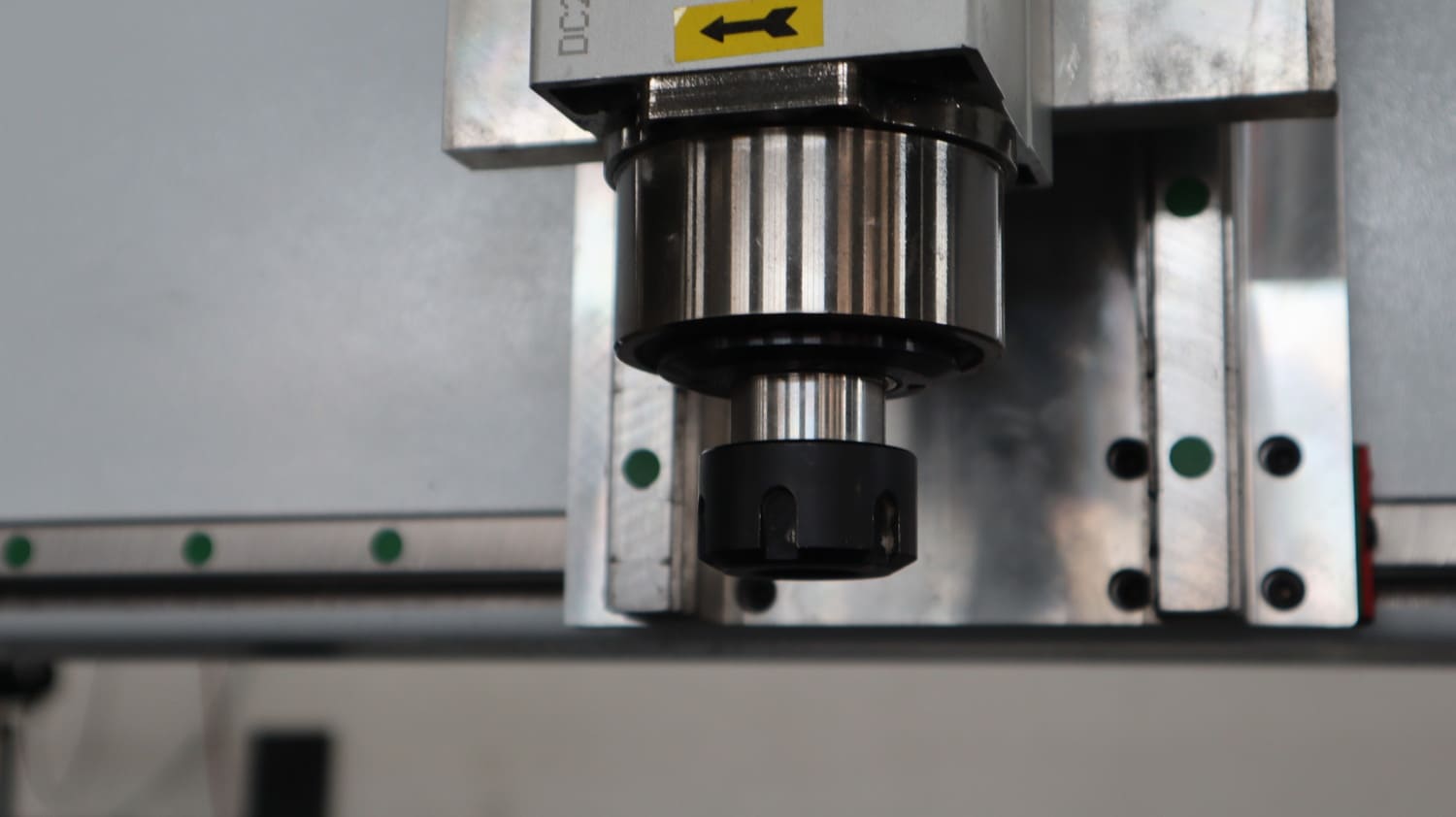

Great spindle precision

CNC spindles serve as the core power, driving the system’s efficient operation.

- CNC Machining – CNC spindle motors serve as the heart of CNC machines, ensuring accuracy and efficiency in machining.

- Precision Engraving – In the field of precision engraving, the stability and precise control of the CNC spindle bring artistic creations to life.

- High-Speed Rotation Applications – From wind power generation to high-speed centrifuges, the high-speed capabilities of CNC spindles are essential。

Choose our CNC spindles, let’s open up a new era of creativity and manufacturing together.

Show Your Thoughts

Our advanced spindle motors offer unparalleled accuracy and performance for all your CNC machining needs. Experience the difference today.

Spindle accuracy test

We understand the importance of every detail. We have adopted a rigorous quality inspection process to ensure that every CNC spindle leaving our factory meets the highest standards.

- Precision Measurement – We ensure dimensional accuracy with state-of-the-art tools.

- Balance Testing – Our CNC spindles are tested for balance to guarantee high-speed stability.

- Performance Evaluation – Each CNC spindle motor undergoes a thorough performance test to verify speed, load capacity, and durability

Choosing our CNC spindles means choosing a guarantee of reliability and performance. We look forward to creating a more brilliant future together with you.

What Our Other Customers Say About Us

FAQ(Frequently Asked Questions)

- Select the appropriate CNC spindle motor type.

- Know the difference between torque and horsepower.

- Determine the necessary spindle speed.

- Select the appropriate motor for your CNC spindle size.

Our spindles have a one-year warranty period and a six-month warranty for the bearings. If any non-artificial damage occurs during this period, our CNC spindles are covered by the warranty service and sharing of round-trip shipping costs, and the repair time is less than one week.

Most of our spindles are shipped from stock, usually within three to five days, except the customized one

Generally speaking, if properly maintained and used, the life of the CNC spindle can reach 2-5 years or even longer. However, if it is not properly maintained, or the CNC spindle is excessively worn or overloaded, its service life will be shortened.

You can read our blogs. Our blogs are authoritative and rich in knowledge about spindles. They are a good choice for you to acquire knowledge about spindles.