Product Categories

( based on power)

Product Categories

( based on collet)

ER11 water-cooled spindle

ER16 water-cooled spindle

ER20 water-cooled spindle

ER25 water-cooled spindle

ER32 water-cooled spindle

LEARN MORE

Application: Wood/Plastic/Aluminum carving/engraving machine, advertisement engraving machine, CNC router machine, small-sized processing center

Features: The 2.2kW Air Cooled Spindle is incredibly powerful and quiet. It is perfectly used on CNC Router Machines.

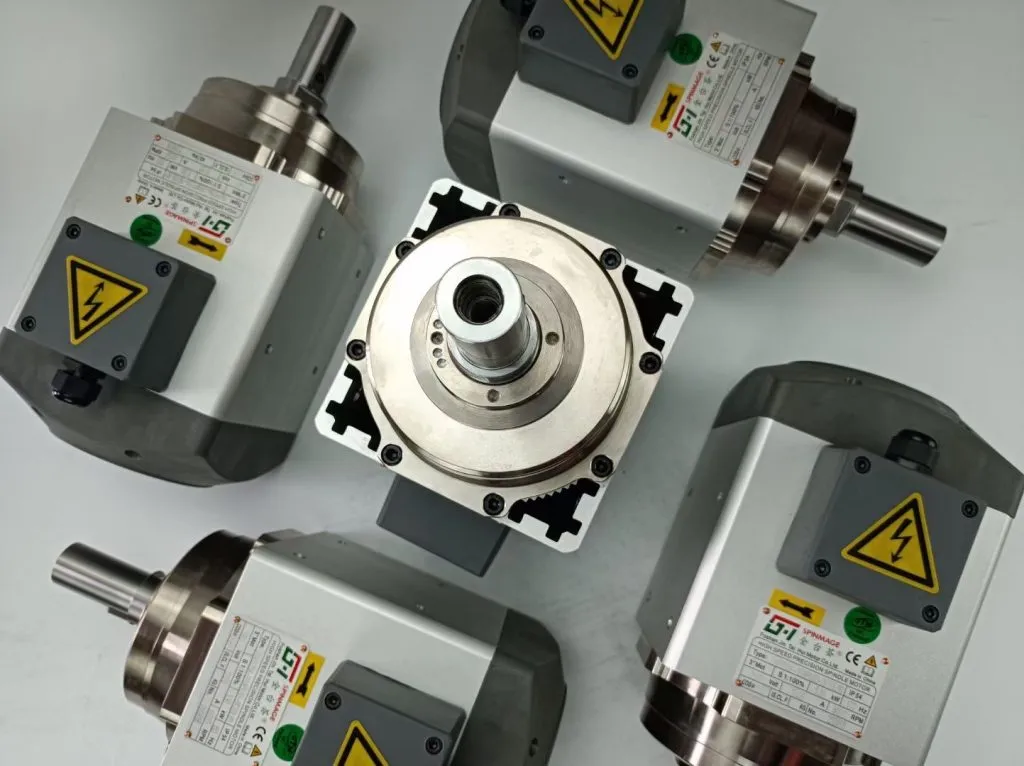

PRODUCTS

Affordable air-cooled spindles for beginners & professional

Main parameter:

| Speed | 18000 rpm, 24000 rpm | |

|---|---|---|

| Voltage | 220 V, 380 V | |

| Current | 5 A, 6 A / 5 A, 10 A / 5.5 A | |

| Frequency | 300 Hz, 400 Hz | |

| Collet | ER11, ER16, ER20, ER25 | |

| Power | 2.2 kW | |

Because the size of air-cooled spindles varies from manufacturer to manufacturer, we will not list all of them here. If you have any questions about the size of the air-cooled spindle you need to upgrade or purchase, please contact us. We have professional technicians to answer your questions.

Notice: The air-cooled spindle should not be operated for a long time. It is recommended to shut down the air-cooled spindle after running for a maximum of four hours at a time and let the spindle rest for two hours.

If you need a spindle with parameters not shown in the sheet, please contact us and we will provide you with professional services.

What are the common inspection items during the maintenance of air-cooled spindles?

- Motor inspection: Check the motor for abnormal sounds, overheating or electrical problems.

- Fan and heat sink inspection: Check whether the fan is clean, rotates smoothly, and whether the heat sink is clogged with dust.

- Tool clamping force: Check whether the tool clamping system is firm and whether there is wear or damage.

- Spindle balancing: Ensure the dynamic balance of the spindle to avoid vibration and wear caused by imbalance.

- Spindle cleaning: Regularly clean the waste, dust, chips and other impurities brought by processing to prevent them from affecting the spindle’s performance.