Product Categories

( based on power)

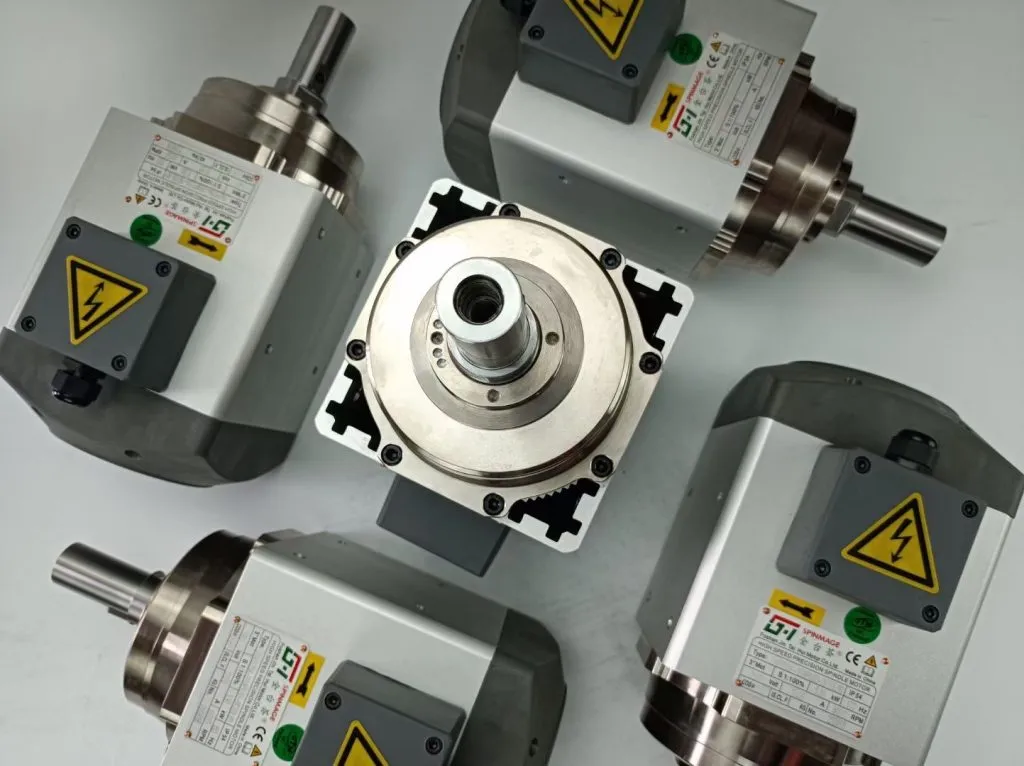

Product Categories

( based on collet)

ER11 water-cooled spindle

ER16 water-cooled spindle

ER20 water-cooled spindle

ER25 water-cooled spindle

ER30 water-cooled spindle

LEARN MORE

Application: This power of water-cooled electric spindle motor is mainly matched with a frequency converter or engraving machine, CNC machine tool, and is used for high-speed profiling, drilling, cutting, engraving, and slot milling of wood, soft metal, plastic, foam, and other materials.

Features: This water-cooled spindle is durable and perfect for commercial use.

Quiet operation and sufficient torque can greatly improve your processing efficiency, and the bearings are strong and durable. There are a variety of sizes to choose from. Matched with a suitable inverter and chiller, your CNC will run for many years. Fast response, strong overload capacity, low noise, and high processing accuracy.High-quality 4 bearings. P4-grade ceramic ball bearings are spindle bearings to increase the service life under high-speed rotation. Lubricated with grease, resistant to 200-degree high temperature. Tightly sealed, double-layer dustproof design.

In addition, we also supply 4.0kw spindles. If you need them, please contact us.

Main parameter:

| Speed | 18000 rpm, 24000 rpm, 30000 rpm |

|---|---|

| Voltage | 220 V, 380 V |

| Current | 4 A, 5 A, 6.8 A / 3.8 A, 13.8 A / 8 A, 9 A, 12-16 A |

| Frequency | 400 Hz, 500 Hz |

| Collet | ER20 |

| Power | 4.5 kW, 3.7/4.0/4.5 kW |

If you need a spindle with parameters not shown in the sheet, please contact us and we will provide you with professional services.

PRODUCTS

Affordable water-cooled spindles for beginners & professional

Specifications for use of electric spindles

- Preparation: Before starting the CNC router spindle, ensure its cooling system works normally. This is crucial because the cooling system helps maintain the spindle motor’s temperature and prevents damage caused by overheating. Before starting, check whether the fan and water pump are operating normally. CNC router spindles with a water cooling system should pay special attention to whether there are impurities in the cooling water and ensure the water path is unobstructed.

- Gradual preheating: Following the low speed to high speed is recommended, and gradually increasing the speed when starting the electro spindle. The preheating process usually takes 5 to 20 minutes, which allows the electric spindle to have a smooth transition before reaching the speed and stable operation state required for processing. This preheating method helps protect the spindle and reduce wear caused by temperature changes. To extend the service life of the spindle, it is recommended to stop the machine for two hours every day.

- Avoid impact and knocking: During the use of the electro spindle, it is strictly forbidden to knock or hit the spindle clamp and the end face thread of the rotor. This behavior may reduce the life of the electric spindle components and affect its use effect. Correct operation and maintenance are the keys to ensuring long-term stable operation of the equipment.

- Tool change after cooling: Tool change should be performed after the CNC router spindle has completely cooled. Avoid changing tools at high temperatures, which can reduce tool installation errors caused by thermal expansion and protect the spindle from thermal stress.

- Correctly handle fixture problems: If you encounter a situation where the fixture is stuck, it is strictly forbidden to use knocking to remove the fixture. The correct approach is to remove the chuck using tools such as pliers without damaging the rotor shaft thread. Doing so can avoid shortening the spindle’s service life and ensure the machined workpiece’s quality. If the fixture has lost its precision, it should be replaced immediately to ensure the accuracy and efficiency of the machining process.

Precautions for use

- (1) The drive and frequency converter must be correctly matched according to the nameplate of the electric spindle to drive the spindle, and the power supply, voltage and frequency must be adjusted.

- (2) The spindle cannot rotate in the opposite direction; ensure the spindle UVW wiring is correct before use.

- (3) Under normal circumstances, when the surface temperature of the water-cooled spindle is greater than the ambient temperature by more than 20 degrees, it can be considered that the spindle is hot and should be stopped immediately for cooling, forced cooling or cooling system inspection.