Introduction

The CNC spindle is a crucial component in a CNC machine. Choosing the proper cooling method is vital, as the spindle is a core component. There are two main types of cooling methods for spindles: water cooling and air cooling. Ignoring the appropriate cooling method and unthinkingly choosing it may lead to severe consequences, such as reducing the service life of the spindle or even burning it out. Next, I’d like to talk more about the differences between these two cooling methods.

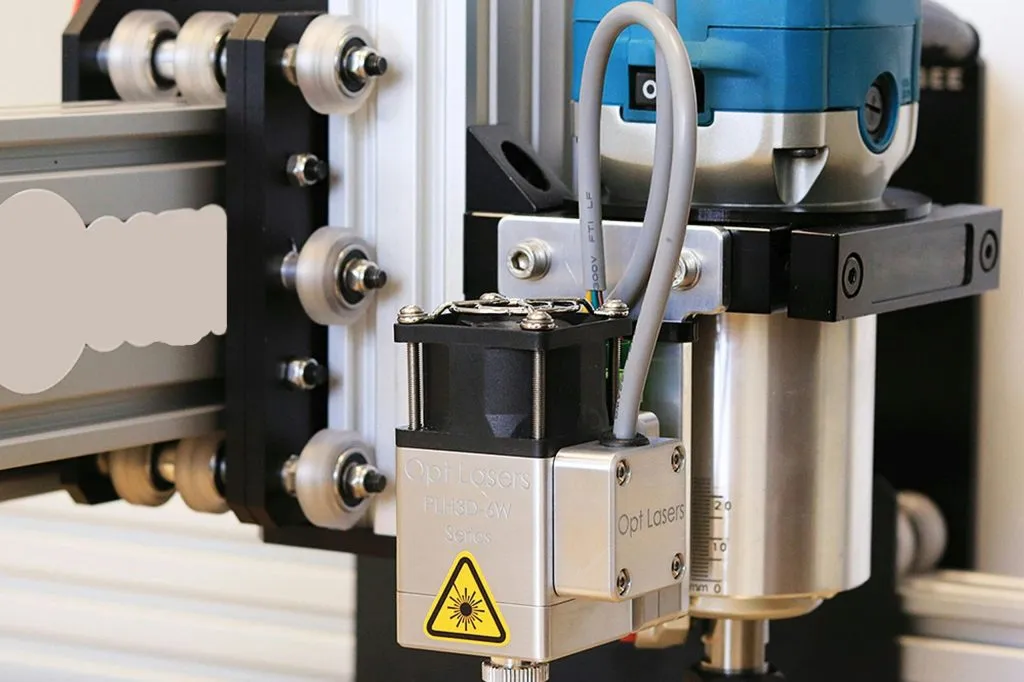

![Air cooling OR water cooling CNC spindle, ]](https://spindlemotorshop.com/wp-content/uploads/2024/08/IMG_6341.jpg.webp)

Advantages of water-cooled spindle:

- Excellent heat dissipation: As we all know, water has the most significant specific heat capacity in nature. Therefore, water-cooled spindles cool the heat generated by the spindle after high-speed rotation through water circulation. The heat dissipation performance is good, and the temperature of the water after circulation will not exceed 40 degrees. It can adapt to long working hours.

- Low noise: Because its cooling system does not rely on fans. Water-cooled spindles are virtually noiseless, providing you with a more comfortable and quiet working environment.

- Long service life: If the water circulation system is properly cleaned and maintained, the service life of the water-cooled spindle can be very long.

- Excellent machining accuracy: The axial and radial runout of the water-cooled spindle is less than 0.03mm, and the rotation speed is very high. During the machining process, any minor movement of the spindle is maintained within a controlled limit. This ensures the surface flatness and dimensional accuracy of the workpiece

Disadvantages of water-cooled CNC spindle:

- High maintenance cost: The water cooling system needs to be replaced regularly and cleaned, and it is necessary to frequently check and dredge pipelines and other water circulation components to prevent blockages.

- Relatively complex structure: The water cooling system requires the installation of a corresponding water circulation system, including but not limited to water pumps, water pipes, inlets and outlets, and other components. The installation and maintenance are relatively complex.

- High environmental requirements: In cold areas, the water cooling system may cause the spindle or even the entire CNC machine to have problems due to the freezing of water in winter. In hot areas, water will evaporate due to high temperatures. If not checked in time, it may lead to severe consequences, such as reducing the service life of the CNC spindles or even burning out the spindle.

Advantages of air-cooled spindle:

- Easy installation: Air-cooled spindles rely on their fans to cool down, and the installation and use are relatively simple. They are less affected by external factors and can be used in most places.

- Low maintenance cost: There is no need to regularly replace the cooling medium like the water cooling system, so the maintenance cost is relatively low.

- Strong adaptability: Air-cooled spindles can adapt to various environments and are not limited by region. Especially in the cold area, they can avoid the problem of freezing water in winter.

- Good portability: Air-cooled spindles eliminate the complex water circulation cooling system of water-cooled spindles, making them more convenient than water-cooled spindles.

Disadvantages of air-cooled CNC spindle:

- Relatively poor heat dissipation effect: Compared with water cooling, the heat dissipation effect of air cooling may be better than the water cooling system, especially under long-term or high-intensity working conditions. Long-term operation will lead to heat accumulation, which cannot be effectively dissipated, affecting the stability and life of the spindle.

- Loud noise: Due to the reliance on fans for cooling, air-cooled spindles may generate a lot of noise during operation, making the workplace noisy.

- Affect accuracy: The axial and radial runout of the air-cooled spindle motor may not be as precise as that of the water-cooled spindle motor. Therefore, water-cooled spindles are better for precision machining.

- Performance: If an air-cooled spindle with the same performance as a water-cooled spindle is needed, it is usually much more expensive than the corresponding water-cooled spindle. In addition, the convenience of operation and the poor requirements for the working environment are also factors that make the air-cooled spindle expensive.

Conclusion

Water-cooled spindles perform better in heat dissipation performance and noise control. But they require more maintenance and may face freezing problems in winter. Air-cooled spindles are simple to install and maintain and have strong adaptability but may not be as good as water-cooled spindles in terms of heat dissipation effect and noise. Compared with water-cooled spindles, air-cooled spindles are usually more expensive. It is recommended that users choose according to their specific usage requirements and environmental conditions when selecting which type of cooling method to use for the spindle.

Summary FAQ Based on the Article

What are the advantages of water-cooled spindles?

What are the disadvantages of water-cooled spindles?

What are the advantages of air-cooled spindles?

What are the disadvantages of air-cooled spindles?

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors

- If you need any CNC spindle, please contact us.