Are 3D Printers CNC Machines?

In the rapidly evolving world of manufacturing technology, 3D printers and CNC machines have become integral tools for creating complex parts and prototypes. However, there’s often confusion about whether 3D printers can be classified as CNC machines. This article aims to demystify the relationship between these two technologies, exploring their similarities, differences, and unique applications in modern manufacturing.

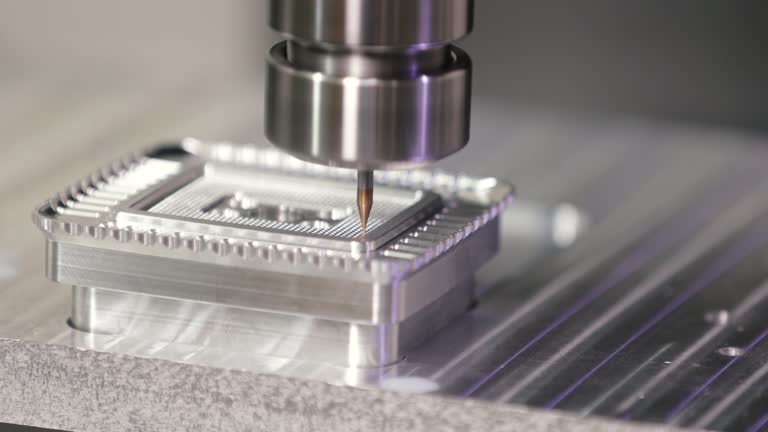

Understanding CNC Machines

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry since their introduction in the 1940s. These versatile tools use computer programming to control the movement of machinery and tools, allowing for precise and repeatable production of parts.

CNC machines typically operate through subtractive manufacturing, where material is removed from a solid block to create the desired shape. This process is highly accurate and can work with a wide range of materials, including metals, plastics, and wood.

Some key characteristics of CNC machines include:

- High precision and repeatability

- Ability to work with a variety of materials

- Capable of producing complex geometries

- Ideal for both prototyping and mass production

One example of a CNC machine used in manufacturing is the 2.2KW ER20 Air-Cooled Spindle, which is perfect for intricate cutting and shaping tasks.

The Rise of 3D Printing Technology

3D printing, also known as additive manufacturing, has gained significant popularity in recent years. Unlike traditional CNC machines, 3D printers build objects layer by layer, adding material rather than removing it.

This technology has opened up new possibilities in manufacturing, allowing for the creation of complex geometries that would be difficult or impossible to achieve with traditional subtractive methods.

Key features of 3D printing include:

- Ability to create complex internal structures

- Reduced material waste compared to subtractive manufacturing

- Rapid prototyping capabilities

- Customization of individual parts without additional tooling costs

Comparing 3D Printers and CNC Machines

While both 3D printers and CNC machines are computer-controlled manufacturing tools, they differ in several key aspects:

- Manufacturing Process: CNC machines use subtractive manufacturing, while 3D printers use additive manufacturing.

- Material Usage: CNC machines can work with a wider range of materials, including metals, while 3D printers are typically limited to plastics and some metals.

- Precision: CNC machines generally offer higher precision and better surface finishes compared to most 3D printers.

- Speed: For large-scale production, CNC machines are often faster, while 3D printers excel at rapid prototyping of individual parts.

- Waste: 3D printing produces less waste material compared to CNC machining, which generates chips and offcuts.

“While both technologies have their strengths, the choice between CNC machining and 3D printing often depends on the specific requirements of the project, including material, precision, and production volume.” – Manufacturing Expert

Are 3D Printers Considered CNC Machines?

The question of whether 3D printers can be classified as CNC machines is somewhat contentious in the manufacturing community. Technically speaking, 3D printers do use computer numerical control to guide their operations, much like traditional CNC machines.

However, the fundamental difference in their manufacturing processes – additive vs. subtractive – leads many to consider them as distinct categories of manufacturing technology.

That being said, there are hybrid machines that combine both 3D printing and CNC machining capabilities, blurring the lines between these technologies.

Applications of CNC Machines and 3D Printers

Both CNC machines and 3D printers have found their place in various industries, each excelling in different applications:

CNC Machines:

- Aerospace: Production of precision components

- Automotive: Manufacturing of engine parts and custom components

- Medical: Creation of implants and surgical instruments

- Woodworking: Furniture production and intricate wood carving

For instance, the 4.5KW ER32 Air-Cooled Spindle is often used in high-precision CNC applications across these industries.

3D Printers:

- Product Design: Rapid prototyping of new concepts

- Medical: Custom prosthetics and anatomical models

- Architecture: Creating detailed scale models

- Education: Hands-on learning tools for STEM subjects

The Future of Manufacturing: Integration of Technologies

As manufacturing technology continues to evolve, we’re seeing increased integration between CNC machining and 3D printing. This convergence is leading to new possibilities in hybrid manufacturing processes.

Some advantages of combining these technologies include:

- Ability to create complex internal geometries with 3D printing, followed by precision finishing with CNC machining

- Reduced material waste by using additive methods for the bulk of the part and subtractive methods for critical surfaces

- Increased flexibility in material choices and part designs

Choosing Between CNC Machining and 3D Printing

When deciding between CNC machining and 3D printing for a project, several factors should be considered:

- Material Requirements: If the part needs to be metal or requires specific material properties, CNC machining might be the better choice.

- Precision: For parts requiring tight tolerances, CNC machining generally offers higher accuracy.

- Production Volume: For large-scale production, CNC machining is often more efficient, while 3D printing excels at low-volume or custom parts.

- Geometric Complexity: If the part has intricate internal structures, 3D printing may be the only viable option.

- Time Constraints: 3D printing can often produce prototypes faster, but CNC machining may be quicker for larger production runs.

- Cost: While 3D printing can be cost-effective for small runs, CNC machining often becomes more economical at higher volumes.

For high-precision CNC applications, tools like the 3.5KW ER20 Air-Cooled Spindles can provide the accuracy and power needed for complex machining tasks.

The Impact on Traditional Manufacturing

The rise of 3D printing and advanced CNC technology has had a significant impact on traditional manufacturing methods. Some key changes include:

- Increased customization capabilities

- Reduced lead times for prototyping and small-batch production

- Democratization of manufacturing, with more accessible tools for small businesses and individuals

- Shift towards digital inventory and on-demand production

Environmental Considerations

Both CNC machining and 3D printing have environmental implications that should be considered:

CNC Machining:

- Generates more waste material

- Often uses more energy due to the cutting process

- Can work with recyclable materials

3D Printing:

- Produces less waste

- Some materials used are not easily recyclable

- Potential for distributed manufacturing, reducing transportation emissions

Skills and Training for Modern Manufacturing

As manufacturing technology evolves, so do the skills required to operate and maintain these machines. Both CNC machining and 3D printing require specific knowledge and training:

CNC Machining:

- Understanding of G-code programming

- Knowledge of cutting tools and materials

- Skills in CAD/CAM software

3D Printing:

- Familiarity with 3D modeling software

- Understanding of different printing technologies and materials

- Post-processing techniques

The Role of Software in Manufacturing

Software plays a crucial role in both CNC machining and 3D printing. Advanced CAD/CAM programs allow for:

- Complex part design

- Simulation and optimization of manufacturing processes

- Integration with machine controls for seamless production

Quality Control and Inspection

Ensuring part quality is crucial in both CNC machining and 3D printing. Methods of quality control include:

- Use of coordinate measuring machines (CMMs)

- 3D scanning for part verification

- Non-destructive testing techniques

Case Studies: Successful Applications

CNC Machining:

A aerospace company used CNC machining with a 6KW ER32 Air-Cooled Spindle to produce lightweight, high-strength components for a new aircraft design, resulting in significant fuel efficiency improvements.

3D Printing:

A medical device startup used 3D printing to rapidly prototype and iterate on a new surgical tool design, reducing development time from months to weeks.

FAQs

What are the main differences between CNC machines and 3D printers?

CNC machines use subtractive manufacturing, removing material to create parts, while 3D printers use additive manufacturing, building parts layer by layer. CNC machines generally offer higher precision and can work with a wider range of materials, while 3D printers excel at creating complex geometries and are ideal for rapid prototyping.

Can 3D printers produce metal parts?

Yes, some advanced 3D printers can produce metal parts using techniques like selective laser sintering (SLS) or direct metal laser sintering (DMLS). However, these machines are typically more expensive and less common than plastic 3D printers.

Are CNC machines more accurate than 3D printers?

In general, CNC machines offer higher accuracy and better surface finishes compared to most 3D printers. However, the gap is narrowing as 3D printing technology continues to improve.

Which is more cost-effective for small-scale production, CNC machining or 3D printing?

For small-scale production or prototyping, 3D printing is often more cost-effective due to lower setup costs and reduced material waste. However, as production volume increases, CNC machining typically becomes more economical.

How do I choose between CNC machining and 3D printing for my project?

The choice depends on factors such as material requirements, precision needs, production volume, geometric complexity, time constraints, and budget. Consider these factors carefully and consult with manufacturing experts to make the best decision for your specific project.

Conclusion

While 3D printers and CNC machines share the common ground of computer-controlled manufacturing, they represent distinct technologies with unique strengths and applications. 3D printers excel in rapid prototyping and creating complex geometries, while CNC machines offer higher precision and a wider range of material options.

Rather than viewing these technologies as competitors, the manufacturing industry is increasingly recognizing the value of integrating both CNC machining and 3D printing in complementary ways. This hybrid approach allows for the creation of parts that combine the best features of both technologies, opening up new possibilities in design and production.

As these technologies continue to evolve, we can expect to see further innovations that blur the lines between additive and subtractive manufacturing. For now, understanding the strengths and limitations of each technology allows manufacturers to make informed decisions about which method is best suited for their specific needs.

Whether you’re considering a high-powered CNC spindle for precision machining or exploring the possibilities of 3D printing, the future of manufacturing is bright with opportunities for innovation and efficiency.