Are CNC Routers Worth It?

In the ever-evolving world of manufacturing and DIY projects, CNC routers have emerged as powerful tools that promise precision, efficiency, and versatility. But for many potential buyers, a crucial question lingers: are CNC routers worth it? This comprehensive guide will delve into the world of CNC routers, exploring their benefits, costs, and potential return on investment to help you make an informed decision.

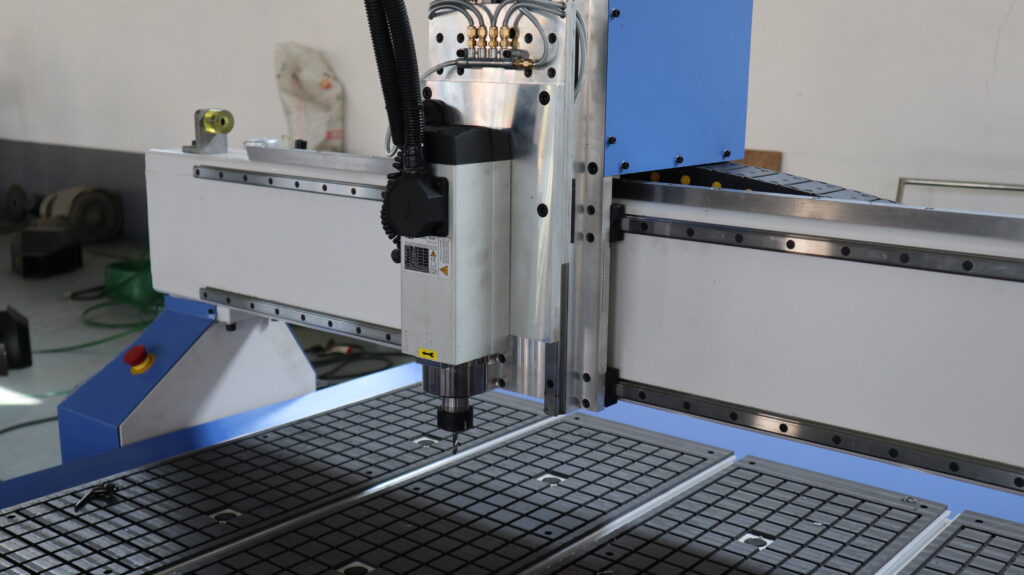

Understanding CNC Routers

CNC routers, or Computer Numerical Control routers, are automated cutting machines used for cutting various materials, including wood, plastics, metals, and composites. These machines use computer-controlled cutting heads to create precise cuts and designs based on digital files.

At the heart of many CNC routers is a powerful spindle, such as the 2.2KW ER20 Air-Cooled Spindle, which provides the cutting force necessary for various materials and applications.

The Benefits of CNC Routers

To determine if CNC routers are worth the investment, let’s first explore their key benefits:

- Precision: CNC routers offer unparalleled accuracy, consistently producing parts with tight tolerances.

- Efficiency: They can work continuously, reducing production time significantly.

- Versatility: From engraving to 3D carving, CNC routers can handle a wide range of tasks.

- Repeatability: Once programmed, a CNC router can reproduce the same design countless times with high consistency.

- Reduced Waste: Precise cutting minimizes material waste, leading to cost savings.

- Complex Designs: CNC routers can create intricate designs that would be difficult or impossible to achieve manually.

Cost Considerations

The cost of a CNC router can vary widely depending on size, features, and capabilities. Here’s a general breakdown:

- Hobby-grade CNC Routers: $1,000 – $5,000

- Mid-range CNC Routers: $5,000 – $25,000

- Industrial CNC Routers: $25,000 – $100,000+

However, the initial purchase price is just one part of the equation. Other costs to consider include:

- Software: CAD/CAM software for design and G-code generation

- Tools and Accessories: Cutting bits, clamps, dust collection systems

- Maintenance: Regular upkeep and potential repairs

- Training: Learning to operate and program the machine effectively

- Power Consumption: Electricity costs for operation

Return on Investment (ROI)

Determining the ROI of a CNC router depends on several factors:

- Production Volume: Higher production volumes generally lead to faster ROI.

- Product Complexity: More complex products that command higher prices can justify the investment.

- Labor Savings: CNC routers can reduce labor costs significantly.

- Material Savings: Precise cutting leads to less waste and more efficient material use.

- New Business Opportunities: A CNC router can allow you to take on projects you couldn’t before.

Let’s look at a hypothetical example:

Initial Investment: $15,000 (Mid-range CNC Router)

Monthly Production: 100 custom signs

Price per Sign: $50

Material Cost per Sign: $10

Labor Cost per Sign (Manual): $20

Labor Cost per Sign (CNC): $5

Monthly Revenue: 100 x $50 = $5,000

Monthly Costs (Manual): 100 x ($10 + $20) = $3,000

Monthly Costs (CNC): 100 x ($10 + $5) = $1,500

Monthly Profit Increase: $3,000 - $1,500 = $1,500

ROI Time: $15,000 / $1,500 = 10 monthsIn this scenario, the CNC router pays for itself in less than a year, making it a worthwhile investment.

Choosing the Right CNC Router

If you’ve decided a CNC router is worth the investment, choosing the right one is crucial. Consider these factors:

- Work Area: Ensure the router can accommodate your largest workpieces.

- Spindle Power: Higher power, like the 4.5KW ER32 Air-Cooled Spindle, allows for faster cutting and harder materials.

- Frame Rigidity: A rigid frame ensures precision and reduces vibration.

- Software Compatibility: Ensure the router works with your preferred design software.

- Support and Training: Look for machines with good customer support and training resources.

- Upgradability: Consider if the machine can be upgraded or expanded in the future.

Learning Curve and Training

One often overlooked aspect when considering if a CNC router is worth it is the learning curve. Operating a CNC router effectively requires skills in:

- CAD (Computer-Aided Design) software

- CAM (Computer-Aided Manufacturing) software

- G-code programming

- Machine setup and operation

- Material properties and cutting strategies

While these skills take time to develop, many find the learning process rewarding and view it as an investment in their capabilities. Many manufacturers offer training programs, and there are numerous online resources available for self-learning.

Maintenance and Longevity

The longevity of your CNC router plays a significant role in its overall worth. Proper maintenance is key to ensuring your machine continues to perform optimally for years to come. Regular maintenance tasks include:

- Lubricating moving parts

- Checking and tightening belts

- Cleaning and inspecting the spindle

- Updating software and firmware

- Replacing worn cutting tools

With proper care, a quality CNC router can last 10-15 years or more, spreading the initial investment over a long period and increasing its overall value.

Expanding Capabilities

One of the advantages of CNC routers is their ability to expand your production capabilities. With a CNC router, you can:

- Take on more complex projects

- Increase production volume

- Offer a wider range of products or services

- Improve product quality and consistency

For example, upgrading to a more powerful spindle like the 6KW ER32 Air-Cooled Spindle can allow you to work with harder materials or increase your cutting speed, opening up new business opportunities.

Industry-Specific Applications

The worth of a CNC router can vary depending on your industry. Let’s explore how CNC routers add value in different sectors:

Woodworking

- Custom cabinetry

- Furniture making

- Intricate wooden signs

- Musical instrument manufacturing

Metalworking

- Custom car parts

- Aerospace components

- Mold making

- Engraving and personalization

Plastics

- Signage

- Display stands

- Custom enclosures

- Prototype development

Education

- STEM learning tools

- Student projects

- Research and development

Each of these industries can benefit from the precision, efficiency, and versatility of CNC routers, potentially justifying the investment.

Environmental Considerations

In today’s environmentally conscious world, the eco-friendliness of your production methods can be a significant factor. CNC routers can contribute to more sustainable manufacturing practices by:

- Reducing material waste through precise cutting

- Lowering energy consumption compared to manual production methods

- Enabling the use of eco-friendly materials that may be difficult to work with manually

- Facilitating repairs and part replacements, extending product lifecycles

These environmental benefits can not only reduce costs but also appeal to environmentally conscious customers, potentially increasing the value proposition of your CNC router.

Competitive Advantage

In many industries, owning a CNC router can provide a significant competitive advantage. It allows you to:

- Offer faster turnaround times

- Produce more consistent quality

- Take on more complex projects

- Customize products more easily

- Reduce labor costs

This competitive edge can lead to increased business opportunities and higher profit margins, further justifying the investment in a CNC router.

Future-Proofing Your Business

Investing in a CNC router can be seen as a way to future-proof your business. As manufacturing continues to evolve towards more automated and digital processes, having CNC capabilities positions you to:

- Adapt to changing market demands

- Integrate with other digital manufacturing technologies

- Attract tech-savvy employees

- Participate in the growing trend of distributed manufacturing

By staying ahead of the curve, you can ensure your business remains competitive in the long term.

Case Studies: Success Stories

To further illustrate the potential worth of CNC routers, let’s look at a few success stories:

- Small Woodworking Shop: A one-person furniture maker invested in a CNC router and was able to triple their production output while maintaining high quality. This led to a 50% increase in revenue within the first year.

- Sign Making Business: By adding a CNC router with a 3.5KW ER20 Air-Cooled Spindles, a sign shop was able to offer more intricate designs and work with a wider range of materials. This resulted in a 30% increase in new clients and a 40% boost in overall revenue.

- Educational Institution: A high school invested in a CNC router for their shop class. Student engagement increased dramatically, and several students went on to pursue careers in advanced manufacturing as a result.

Potential Drawbacks

While CNC routers offer numerous benefits, it’s important to consider potential drawbacks:

- Initial Cost: The upfront investment can be significant, especially for small businesses or hobbyists.

- Learning Curve: It takes time and effort to become proficient in CNC operation and programming.

- Maintenance Requirements: Regular maintenance is necessary to keep the machine running optimally.

- Space Requirements: CNC routers can take up considerable space in a workshop.

- Noise and Dust: CNC routing can be noisy and produce a lot of dust, requiring proper management.

Weighing these factors against the benefits is crucial in determining if a CNC router is worth it for your specific situation.

FAQs

How long does it take to learn to use a CNC router effectively?

While basic operation can be learned in a few weeks, becoming proficient in all aspects of CNC routing, including design and advanced programming, typically takes several months to a year of regular use.

Can a CNC router cut metal?

Yes, many CNC routers can cut soft metals like aluminum. For harder metals, specialized CNC milling machines are typically used.

What’s the difference between a CNC router and a 3D printer?

CNC routers use subtractive manufacturing, removing material to create objects. 3D printers use additive manufacturing, building objects by adding material layer by layer.

How often does a CNC router need maintenance?

Regular maintenance should be performed daily (cleaning), weekly (lubrication), and monthly (more thorough checks). Major maintenance might be needed annually, depending on usage.

Is it better to buy a CNC router or outsource CNC work?

This depends on your production volume, the complexity of your projects, and your long-term business goals. If you frequently need CNC work and have the capacity to learn and maintain a machine, buying might be more cost-effective in the long run.

Conclusion

So, are CNC routers worth it? The answer, as with many significant business decisions, is: it depends. For many businesses and individuals, the precision, efficiency, and versatility offered by CNC routers make them a worthwhile investment. They can open up new business opportunities, increase production capacity, and improve product quality.

However, the worth of a CNC router is not just in its capabilities, but in how well it aligns with your specific needs, goals, and resources. Consider factors such as your production volume, the complexity of your projects, your budget, available space, and willingness to learn new skills.

For those who decide to invest in a CNC router, the rewards can be significant. From increased productivity to the ability to take on more complex projects, a CNC router can be a game-changer for many businesses. The key is to choose the right machine for your needs, invest time in learning to use it effectively, and maintain it properly to ensure longevity.

Remember, the true value of a CNC router extends beyond mere productivity gains. It’s about expanding your capabilities, staying competitive in an increasingly digital manufacturing landscape, and opening up new creative possibilities. Whether you’re a small woodworking shop looking to increase output, a sign maker aiming to offer more intricate designs, or an educator preparing students for the future of manufacturing, a CNC router could be the tool that takes your work to the next level.

Ultimately, while the initial investment may seem daunting, for many, the long-term benefits of owning a CNC router far outweigh the costs. As with any significant business decision, careful consideration of your specific circumstances is crucial. But for those who take the plunge, a CNC router can indeed be a worthwhile investment that pays dividends for years to come.