Can You CNC Wood?

Yes, you can definitely CNC (Computer Numerical Control) wood. In fact, wood is one of the most popular and versatile materials used in CNC machining. This comprehensive guide will explore the process of CNC machining wood, covering techniques, tools, and best practices for both hardwood and softwood projects.

Understanding Wood as a CNC Material

Wood is an excellent material for CNC machining due to its:

- Ease of cutting

- Wide variety of types and grain patterns

- Affordability

- Versatility in applications

Both hardwoods and softwoods can be machined using CNC technology, each with its own characteristics and considerations.

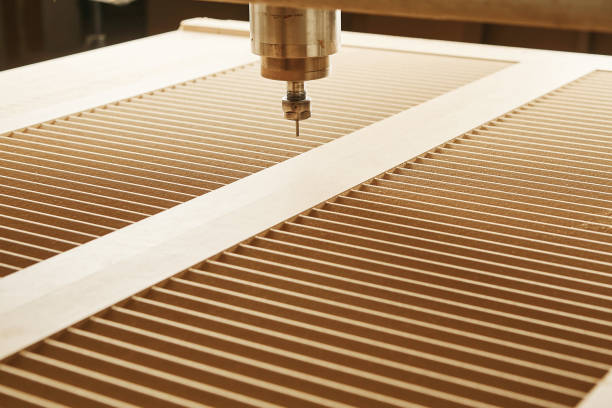

A CNC router suitable for cutting wood

Types of Wood for CNC Machining

Hardwoods

- Oak

- Maple

- Walnut

- Cherry

- Mahogany

Softwoods

- Pine

- Cedar

- Fir

- Spruce

CNC Machining Techniques for Wood

CNC Routing

CNC routing is the most common technique for wood:

- Tool Selection: Use carbide or high-speed steel (HSS) router bits designed for wood.

- Spindle Speed: Higher speeds are typically used. A 2.2KW ER20 Air-Cooled Spindle can handle most wood routing tasks.

- Feed Rate: Adjust based on the wood type and cutting depth.

- Depth of Cut: Multiple shallow passes often yield better results than a single deep cut.

CNC Carving

For intricate 3D designs in wood:

- Use ball nose or v-bit cutters for detailed work.

- Consider a more powerful spindle like the 3.5KW ER20 Air-Cooled Spindles for faster material removal in hardwoods.

CNC Engraving

For text and shallow designs:

- Use fine v-bits or engraving bits.

- Maintain consistent depth for even engraving.

Best Practices for CNC Machining Wood

- Grain Direction: Consider wood grain when planning cuts to minimize tear-out.

- Dust Collection: Use a robust dust collection system to keep your work area clean.

- Tool Selection: Choose the right bit for your specific wood type and project.

- Securing the Workpiece: Use appropriate clamping methods to prevent movement during cutting.

- Finishing Passes: Plan for finishing passes to achieve smooth surfaces.

Recommended Settings for CNC Cutting Wood

Settings can vary based on the specific wood type and machining method. Here are general guidelines:

| Parameter | Softwood | Hardwood |

|---|---|---|

| Spindle Speed | 16,000 – 24,000 RPM | 12,000 – 18,000 RPM |

| Feed Rate | 100 – 200 inches per minute | 60 – 150 inches per minute |

| Depth of Cut | Up to 0.25″ per pass | Up to 0.125″ per pass |

Note: These are starting points and may need adjustment based on your specific setup and project.

Tools for CNC Machining Wood

- Straight Bits: For general cutting and pocketing.

- V-Bits: For engraving and detailed work.

- Ball Nose Bits: For 3D carving and contoured surfaces.

- Compression Bits: For clean cuts on both top and bottom of sheet goods.

- Surfacing Bits: For flattening and smoothing large areas.

Applications of CNC Machined Wood Projects

- Custom furniture

- Decorative wall art

- Signage and lettering

- Intricate wooden sculptures

- Musical instruments

- Architectural elements

- Prototypes and models

Challenges in CNC Machining Wood

- Grain Tear-Out: Wood grain can cause tearing if not cut properly.

- Moisture Content: Wood’s moisture can affect cutting precision and tool life.

- Dust Management: Wood creates significant dust during machining.

- Material Inconsistency: Natural variations in wood can affect cutting consistency.

- Finish Quality: Achieving a smooth finish may require post-processing.

FAQ

1. What’s the best wood for CNC machining?

The best wood depends on your project. Hardwoods like maple or oak offer durability and fine detail, while softwoods like pine are easier to machine and more cost-effective.

2. Can I use my CNC router for both hardwood and softwood?

Yes, most CNC routers can handle both hardwood and softwood. You may need to adjust your speeds and feeds accordingly.

3. How do I prevent tear-out when CNC cutting wood?

Use sharp bits, cut with the grain when possible, and consider using sacrificial backing boards. For through cuts, use compression bits or cut in multiple passes.

4. What’s the best CNC machine for woodworking?

CNC routers are generally best for woodworking. The size and power depend on your specific needs and project scale.

5. Can I use regular woodworking bits in my CNC machine?

While some regular woodworking bits can be used, it’s best to use bits specifically designed for CNC machining to ensure optimal performance and safety.

6. How do I achieve a smooth finish when CNC machining wood?

Use sharp bits, appropriate speeds and feeds, and consider finishing passes with a finer bit. Post-processing with sanding or other finishing techniques may also be necessary.

Conclusion

CNC machining wood opens up a world of possibilities for creating precise, intricate, and repeatable wooden projects. Whether you’re working with hardwoods or softwoods, CNC technology allows for a level of detail and consistency that’s difficult to achieve with traditional woodworking methods.

Success in CNC woodworking comes from understanding the unique properties of different wood types, selecting appropriate tools and machine settings, and implementing effective dust management strategies. By mastering these elements, you can create everything from fine furniture to intricate sculptures with remarkable precision.

Remember that while CNC machining offers great capabilities, it’s a tool that complements rather than replaces traditional woodworking skills. Understanding wood grain, moisture content, and finishing techniques remains crucial for producing high-quality wooden items.

As CNC technology continues to advance, we can expect even more sophisticated methods for machining wood, potentially opening up new applications in furniture design, architecture, and artistic expression. Whether you’re a hobbyist exploring the possibilities of CNC woodworking or a professional looking to enhance your production capabilities, CNC machining of wood offers exciting opportunities for creativity and craftsmanship.