What are the Features of the 1.5kw 24k RPM Water-Cooled Spindle?

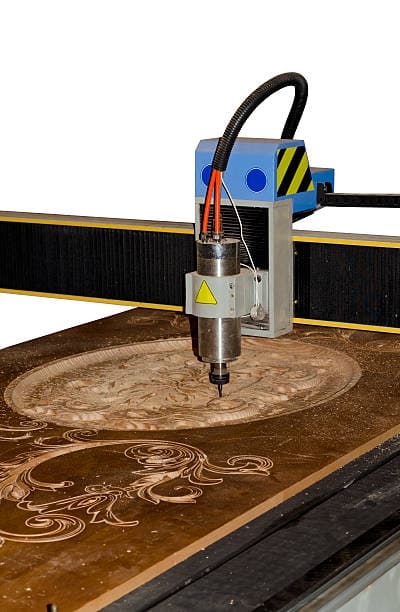

The 1.5kw 24krpm water-cooled CNC spindle motor offers several significant advantages over traditional routers. But what exactly makes this spindle so effective?

This model is engineered for precision, durability, and cooling efficiency, making it ideal for long and detailed woodworking projects. One of the main attractions is its water-cooled system, which prevents overheating, ensuring the spindle can run continuously without compromising performance.

Key Features of the CNC Quiet Spindle:

- Water-Cooling System: This cooling mechanism prevents the spindle from overheating, providing a reliable solution for continuous and demanding tasks.

- High-Speed Operation: The spindle’s 24,000 RPM is designed for smooth and precise cutting operations, particularly when working on complex and detailed woodworking projects.

- Low Noise Levels: Operating much quieter than standard routers, this spindle ensures a more comfortable working environment, especially in home workshops where noise can be an issue.

- Durability: With its advanced design, the CNC router spindle motor is built for longevity, providing excellent return on investment for users who need a reliable, long-lasting tool.

This combination of features makes the 1.5kw 24krpm spindle the ideal choice for professionals and hobbyists alike, especially those who prioritize precision and long operational hours in their woodworking processes.

Benefits of Upgrading to a Quiet CNC Spindle

When comparing the CNC quiet spindle to a traditional table wood router, the advantages are clear. Here’s why you should consider making the switch.

Enhanced Precision and Consistency

The precision offered by a CNC spindle motor far surpasses that of a manual or semi-manual wood router. CNC router spindles provide accuracy to within fractions of a millimeter, allowing you to achieve perfect results with every cut. This level of precision is crucial for intricate woodworking tasks, such as creating custom furniture, carvings, or other detailed pieces.

Moreover, the CNC spindle motor ensures consistent performance. Unlike manual routing, where human error can lead to slight variations, the spindle for CNC performs the same operation repeatedly with no deviation. This is ideal for production environments or projects that require uniformity.

Reduced Noise Levels for Improved Work Environment

If you’ve ever worked with a traditional wood router, you’re familiar with its loud, often ear-piercing noise. CNC quiet spindles, on the other hand, operate with significantly lower noise levels. This not only reduces workplace discomfort but also makes the spindle more suitable for home workshops, shared spaces, or areas where noise pollution is a concern.

Reduced noise levels can also have a positive impact on operator focus and comfort, leading to better overall results in your work. Long woodworking sessions become more enjoyable when you’re not constantly bombarded by high-decibel sounds.

Selecting the Right CNC Spindle for Woodworking

When upgrading from a traditional wood router to a CNC spindle, selecting the right model is crucial. There are several key factors to keep in mind to ensure that your spindle choice aligns with your woodworking goals.

Key Factors to Consider

- Power Output: The 1.5kw spindle provides adequate power for most woodworking tasks, but for heavy-duty work or materials other than wood, you may need to opt for a higher-power spindle. For woodworking, this power range is ideal for detailed projects requiring high precision.

- Cooling System: Water-cooled spindles offer more efficient cooling than air-cooled models, especially during extended operations. This ensures that the spindle can run continuously without overheating, making it suitable for long-duration projects.

- Compatibility: Ensure that the spindle is compatible with your existing CNC router setup. This includes checking mounting brackets, electrical specifications, and software requirements to avoid compatibility issues.

Properly evaluating these factors before making a purchase can prevent costly mistakes and ensure that the spindle you select is the right fit for your specific needs.

Installation and Setup of a CNC Quiet Spindle

Installing a CNC quiet spindle requires a bit of technical know-how, but with proper planning and the right tools, the process can be smooth.

Essential Tools and Equipment for Installation

To successfully install a CNC router spindle motor, you’ll need a few essential tools, such as wrenches, spindle collets, and a coolant system for water-cooled spindles. Additionally, you should have a sturdy frame for your CNC router to support the spindle’s weight and operational force.

Compatibility with Your CNC Machine

Before installation, it’s important to confirm that the spindle is compatible with your CNC machine. Many CNC routers are designed to work with specific spindle types and sizes, and ensuring that the 1.5kw spindle fits your machine will save you time and hassle.

Be sure to also check the electrical requirements. The spindle may require a specific voltage, and ensuring your setup matches these requirements is essential for safe and efficient operation.

Understanding CNC Quiet Spindles

CNC quiet spindles are a technological advancement over traditional routers. To understand their advantages, let’s compare them more closely to conventional woodworking tools.

The Basics of CNC Quiet Spindle Technology

Quiet spindles for CNC machines utilize advanced motor control technologies to reduce vibrations and noise during operation. This not only helps create a quieter work environment but also improves the quality of the work. The reduction in vibration leads to smoother cuts and extends the lifespan of the spindle.

Comparing 1.5kw 24krpm Water-Cooled Spindles to Traditional Routers

Traditional routers may operate at similar speeds, but they generate more noise and heat. The water-cooled design of the CNC spindle allows it to stay cooler for longer, providing extended use times and reducing wear on the motor. Additionally, quiet spindles are specifically engineered for high-speed precision work, making them superior to conventional routers when it comes to detailed woodworking.

FAQs on CNC Quiet Spindles

- How do CNC multi-spindle machines improve production efficiency?

CNC multi-spindle machines allow for simultaneous operations, significantly reducing the time needed for production without sacrificing precision. - Can CNC multi-spindle machines be used for materials other than wood?

Yes, CNC multi-spindle machines are versatile and can handle materials like metals and plastics. The type of spindle used will determine the range of materials that can be processed. - What is the learning curve like for operating CNC multi-spindle machines?

The learning curve varies depending on the operator’s experience with CNC technology, but with proper training, it becomes intuitive. Many modern machines come with user-friendly software interfaces that simplify the process. - How does the cost of CNC multi-spindle machines compare to single-spindle machines?

Multi-spindle CNC machines are typically more expensive due to their increased capabilities and efficiency. However, the long-term benefits often outweigh the initial cost, especially for high-volume production environments. - Where can I find training or resources for CNC multi-spindle machine operation?

Many manufacturers offer training programs, and online resources such as forums, video tutorials, and certification courses can also help operators get up to speed quickly.

Conclusion

In summary, replacing a traditional wood router with a CNC quiet spindle can be a game-changer for your woodworking projects. The 1.5kw 24krpm water-cooled spindle offers superior precision, quieter operation, and better overall efficiency. If you’re looking to enhance your woodworking setup, this CNC spindle motor could be the perfect upgrade.

Summary of Benefits:

- Enhanced Precision: CNC spindles ensure consistent, high-quality cuts with minimal deviations.

- Quieter Operation: Lower noise levels make the spindle ideal for home workshops or shared workspaces.

- Improved Efficiency: Faster, more accurate cuts translate to increased productivity and less rework.

With the right spindle and installation, you can take your woodworking to new heights, ensuring that your projects meet the highest standards of craftsmanship and quality.

How 10 Amps Affect CNC Spindle Performance

The amperage drawn by a CNC spindle motor affects its performance in several key ways. First and foremost, higher amperage means the motor can draw more power, which translates into greater torque and cutting ability. However, drawing too much amperage can lead to increased heat and potential motor failure.

For a 220VAC system, drawing 10 amps gives a power output of 2.2 kW. This is more than enough for many standard CNC applications, including wood routing, light metal cutting, and engraving.

Material Resistance and Its Impact on Spindle Power

One often-overlooked factor in calculating CNC spindle power is the material you’re working with. Different materials offer varying levels of resistance, which can impact how much power your spindle motor requires to make precise cuts.

For example, cutting soft materials like wood with a spindle for CNC machine requires significantly less power than cutting through tough metals like stainless steel. The higher the material resistance, the more strain is put on the spindle motor.

The Significance of Spindle Speed in Power Consumption

Spindle speed plays a critical role in determining how much power your CNC machine consumes. Higher spindle speeds increase the rate of material removal, but they also require more power. For instance, a spindle CNC running at 24,000 RPM will draw significantly more power than one running at 12,000 RPM.

Finding the balance between speed and power consumption is key. Faster isn’t always better, especially when cutting materials that generate a lot of heat. The CNC router spindles you choose must be matched not only to the material but also to the desired speed and power output.

Cooling Systems and Their Effect on Power Efficiency

CNC spindles generate significant amounts of heat during operation, particularly when running at high speeds or cutting dense materials. Cooling systems are essential for maintaining power efficiency and prolonging the lifespan of the motor.

There are two main types of cooling systems used in CNC spindles: air-cooled and water-cooled. Water-cooled spindles tend to offer better efficiency, as water is more effective at absorbing heat than air.

Standard Power Ratings and What They Mean for Users

Understanding the standard power ratings of CNC spindles is crucial when choosing the right motor for your machine. Most CNC spindle motors are rated between 0.5 kW and 7.5 kW, depending on their size and intended application. For small workshops or hobbyists, a spindle rated between 1.5 kW and 3 kW is often sufficient.

For industrial applications requiring heavy-duty cutting, a higher power rating of 4 kW or more may be necessary, especially when working with metals.

High-Power vs. Low-Power Spindles: A Comparative Analysis

Choosing between high-power and low-power spindles depends largely on the type of work you plan to do. High-power CNC spindles (4 kW or more) are ideal for industrial use, where fast, deep cuts in hard materials are required. However, they consume more energy and generate more heat.

On the other hand, low-power spindles (under 3 kW) are sufficient for hobbyist projects and light commercial work. They are more energy-efficient but may struggle with harder materials or high-speed cutting.

Tools and Formulas for Accurate Power Calculation

To calculate spindle power accurately, you can use several tools and formulas. Aside from the basic equation (P = V × I), you can also factor in the efficiency of the motor and the load being placed on the spindle.

Specialized CNC software can also help by providing real-time data on power consumption, speed, and torque, allowing you to make adjustments on the fly.

Real-World Applications: Calculating Power for Specific Projects

In real-world CNC applications, accurately calculating spindle power is essential for project success. For example, when working with a multi-spindle CNC machine, you may need to balance multiple spindle power settings based on the material, cutting depth, and desired finish.

Miscalculating spindle power can lead to poor performance, tool wear, or even machine failure.

Advances in Spindle Design for Better Power Management

Recent advances in CNC spindle design have focused on improving power management. Innovations such as variable-frequency drives (VFDs) allow machinists to adjust the spindle speed and torque dynamically, optimizing power usage for different tasks.

Other developments include brushless motors, which offer higher efficiency and longer lifespans compared to traditional brushed motors.

The Role of Software in Optimizing Spindle Power Usage

Software plays an increasingly important role in CNC spindle power management. Modern CNC software can optimize spindle speed, feed rate, and cutting depth automatically based on the material being processed.

Additionally, many CNC programs offer real-time monitoring, allowing operators to track spindle performance and make adjustments as needed.

Frequently Asked Questions

- What is the ideal power rating for a home CNC project?

- Can I upgrade my CNC spindle for higher power efficiency?

- How does ambient temperature affect CNC spindle power?

- Are there any safety concerns with high-power CNC spindles?

- Can software help in reducing the power consumption of my CNC machine?

Key Takeaways

- CNC spindle power is calculated using the formula P = V × I.

- Power ratings in kilowatts help compare different spindles efficiently.

- Material resistance, spindle speed, and cooling systems all impact power efficiency.

- High-power spindles are ideal for industrial applications, while low-power spindles suit hobbyist needs.

- Advances in spindle design and CNC software offer better power management and improved efficiency.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.