Do It Yourself CNC Milling Machine

Building your own CNC (Computer Numerical Control) milling machine can be an exciting and rewarding project for enthusiasts and professionals alike. This comprehensive guide will explore the process of creating a DIY CNC milling machine, covering essential components, design considerations, and best practices.

Understanding CNC Milling Machines

A CNC milling machine is a computer-controlled cutting tool used to remove material from a workpiece to create custom parts and designs. Key components include:

- Frame and base

- Spindle

- Motion system (linear rails and ball screws)

- Motors (stepper or servo)

- Controller

- Software

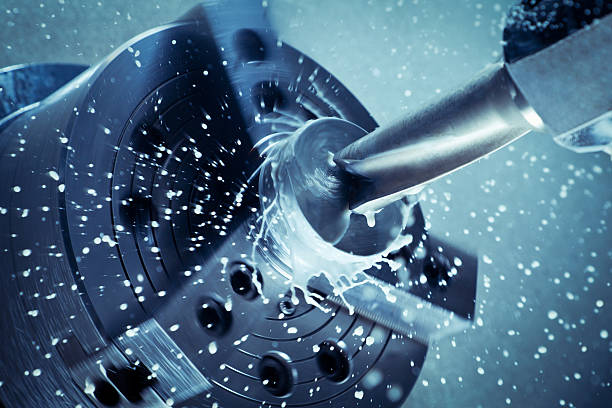

A typical CNC milling machine setup

Steps to Build a DIY CNC Milling Machine

1. Design and Planning

- Determine the size and capabilities of your machine

- Create detailed plans and 3D models

- Establish a budget and timeline

2. Frame Construction

- Choose materials: steel, aluminum, or epoxy granite

- Ensure rigidity and vibration dampening

- Consider using welded steel or bolted aluminum extrusions

3. Motion System

- Install linear rails and ball screws for each axis

- Ensure precise alignment and smooth movement

- Consider using recirculating ball bearings for reduced friction

4. Spindle Selection

- Choose a spindle based on your needs and budget

- Options include:

- 2.2KW ER20 Air-Cooled Spindle for general-purpose use

- 3.5KW ER20 Air-Cooled Spindles for more demanding applications

5. Motor and Drive System

- Select stepper or servo motors based on required torque and precision

- Install motor drivers and power supply

- Ensure proper wiring and cooling

6. Controller Setup

- Choose a CNC controller (e.g., Mach3, LinuxCNC, or custom Arduino-based solution)

- Configure the controller for your machine’s specifications

- Set up limit switches and home positions

7. Software Integration

- Install CAD/CAM software for designing and generating G-code

- Configure post-processors for your specific machine

- Test and calibrate the system

Key Considerations for DIY CNC Milling Machines

Frame Material Choice

- Steel: Strong and rigid, but heavy and can be difficult to work with

- Aluminum: Lighter and easier to machine, but less rigid than steel

- Epoxy Granite: Excellent vibration dampening, but requires special casting techniques

Ball Screws vs. Lead Screws

- Ball screws offer higher precision and efficiency

- Lead screws are cheaper but have more backlash and lower efficiency

Spindle Considerations

- Power requirements for your typical workpieces

- Cooling system (air-cooled vs. water-cooled)

- Tool changing capabilities (manual vs. automatic)

Controller Options

- PC-based (e.g., Mach3, LinuxCNC)

- Standalone controllers

- Custom solutions using microcontrollers

Challenges in Building a DIY CNC Milling Machine

- Precision alignment: Ensuring all axes are square and true

- Rigidity: Minimizing flex and vibration during operation

- Electrical integration: Proper wiring and noise reduction

- Software configuration: Setting up and fine-tuning the control software

- Safety considerations: Implementing emergency stops and enclosures

Benefits of Building Your Own CNC Milling Machine

- Cost savings: Potentially lower cost compared to commercial machines

- Customization: Tailor the machine to your specific needs

- Learning experience: Gain in-depth knowledge of CNC technology

- Upgradability: Easily modify and improve your machine over time

FAQ

1. How much does it cost to build a DIY CNC milling machine?

Costs can range from $1,000 for a basic setup to $10,000+ for a more advanced machine, depending on components and capabilities.

2. What skills do I need to build a CNC milling machine?

Basic mechanical and electrical skills are essential. Knowledge of CAD/CAM software and CNC programming is also helpful.

3. How long does it take to build a DIY CNC milling machine?

The time frame can vary greatly, from a few weeks for a simple machine to several months for a more complex build.

4. Can a DIY CNC milling machine be as accurate as commercial machines?

With careful design and quality components, a DIY machine can approach the accuracy of commercial machines, but may require more tuning and maintenance.

5. What materials can a DIY CNC milling machine cut?

Depending on its design and power, a DIY machine can cut wood, plastics, aluminum, and even steel with the right setup.

6. Is it cheaper to build or buy a CNC milling machine?

Building can be cheaper, especially for larger or more specialized machines. However, the time investment should be considered in the overall cost.

Conclusion

Building a DIY CNC milling machine is a challenging but rewarding project that can provide you with a powerful tool tailored to your specific needs. By carefully selecting components, focusing on rigidity and precision, and investing time in proper setup and calibration, you can create a machine that rivals commercial models in many aspects.

The process of building your own CNC milling machine offers not just potential cost savings but also an invaluable learning experience. You’ll gain in-depth knowledge of CNC technology, machine design principles, and the intricacies of precision engineering. This knowledge can be applied to future projects, machine maintenance, and even career opportunities in manufacturing and engineering fields.

However, it’s important to approach this project with realistic expectations. Building a high-quality CNC milling machine requires time, patience, and a willingness to troubleshoot and iterate on your design. The final result may not have all the features or the polished appearance of a commercial machine, but it will be uniquely yours and can be continually improved and upgraded.

Remember that safety should be a top priority throughout the build process and during operation. Implement proper safety features, including emergency stops, enclosures, and dust collection systems. Always follow best practices for electrical wiring and mechanical assembly.

As you embark on your DIY CNC milling machine project, take advantage of online resources, forums, and community support. Many enthusiasts have shared their experiences, plans, and tips, which can be invaluable in overcoming challenges and optimizing your design.

Whether you’re a hobbyist looking to expand your capabilities or a professional seeking a custom solution for your workshop, building your own CNC milling machine can be a fulfilling endeavor. It’s a project that combines mechanical engineering, electronics, software integration, and creativity, resulting in a powerful tool that can open up new possibilities for your manufacturing and prototyping needs.