EDGEBANDER spindles

- The edge bander spindle is installed in the edge banding machine. It is mainly used for straight-edge banding and trimming medium-density fiberboard, blockboard, solid wood board, particleboard, polymer door panel, plywood, etc. It is suitable for manufacturing various board furniture, such as cabinets, wardrobes, office furniture, kitchen furniture, and other board edge banding.

- It can simultaneously complete the cutting, aligning, chamfering, rough trimming, delicate trimming, and other steps of the double-sided glued-edge banding. Using the edge banding machine can significantly improve the quality of furniture products and is one of the indispensable equipment in modern furniture manufacturing.

features of edgebander spindles

- High-performance bearings: The high-specification bearing design can provide higher load-bearing capacity and better rigidity, ensure that the spindle remains stable at high speeds, and reduce axial and radial runout, thereby improving the accuracy and quality of edge sealing.

- High precision: High precision is one of the essential characteristics of the edge banding machine spindle. It ensures the fineness and consistency of the edge banding process, makes the edge banding strip and the edge of the board more closely combined, and improves the beauty and durability of the product.

- Space-saving: The edge banding machine spindle is compactly designed and occupies little space, which helps to improve the space utilization of the production workshop.

Products

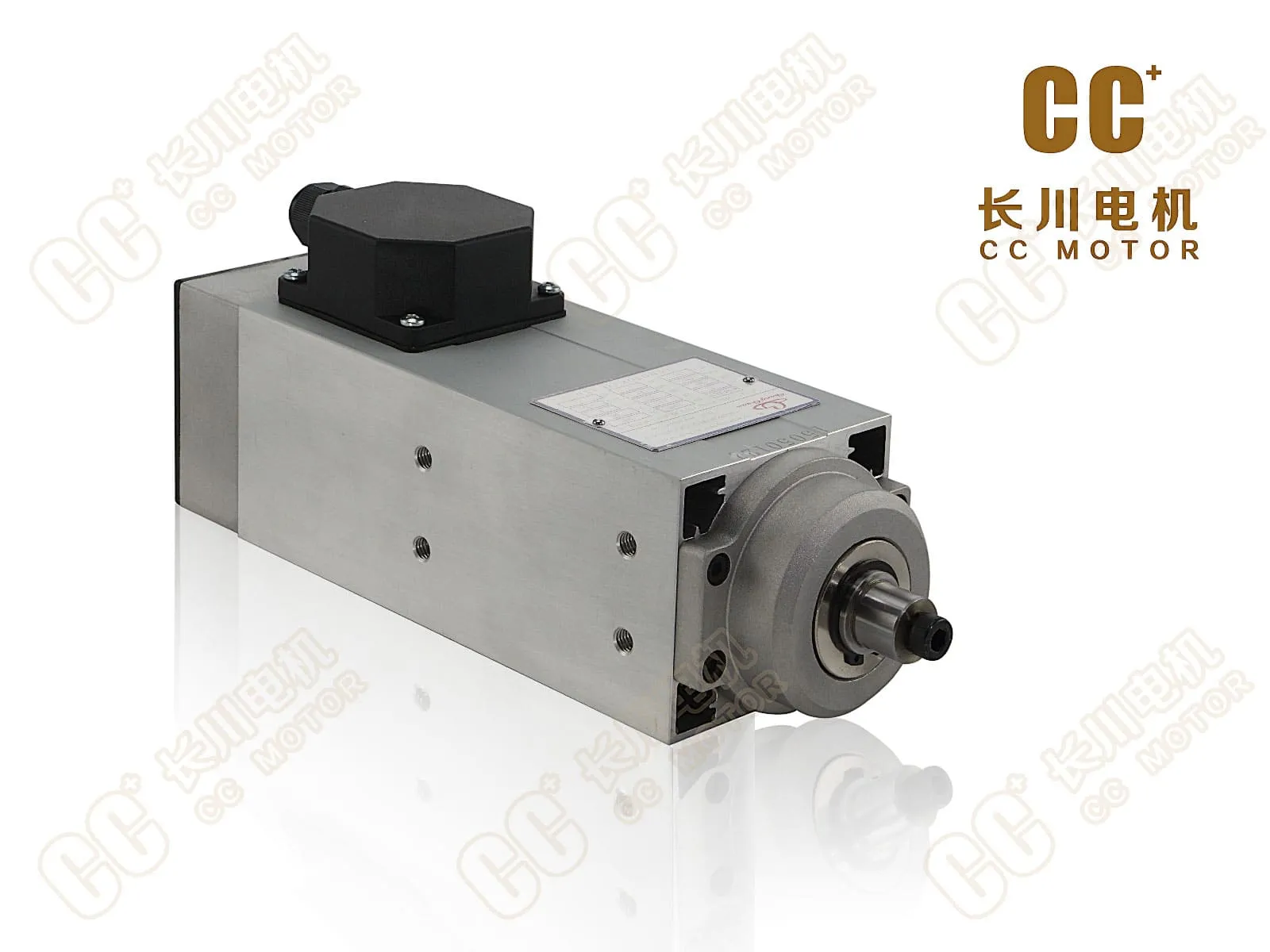

Pre-milling Motor

- The pre-milling motor in the edge banding machine is a key component in the edge banding process. It is specially used to perform preliminary processing on the edge of the board to lay the foundation for the subsequent edge banding process.

- Its main function is to ensure the flatness and smoothness of the edge of the board, thereby improving the edge banding effect and the quality of the finished product.

End Trimming Motor

- The edge bander spindle moves through precise linear guide rails, automatically tracks the mold, and adopts a high-frequency, high-speed motor fast-cutting structure to ensure the cutting surface is smooth and burrs-free.

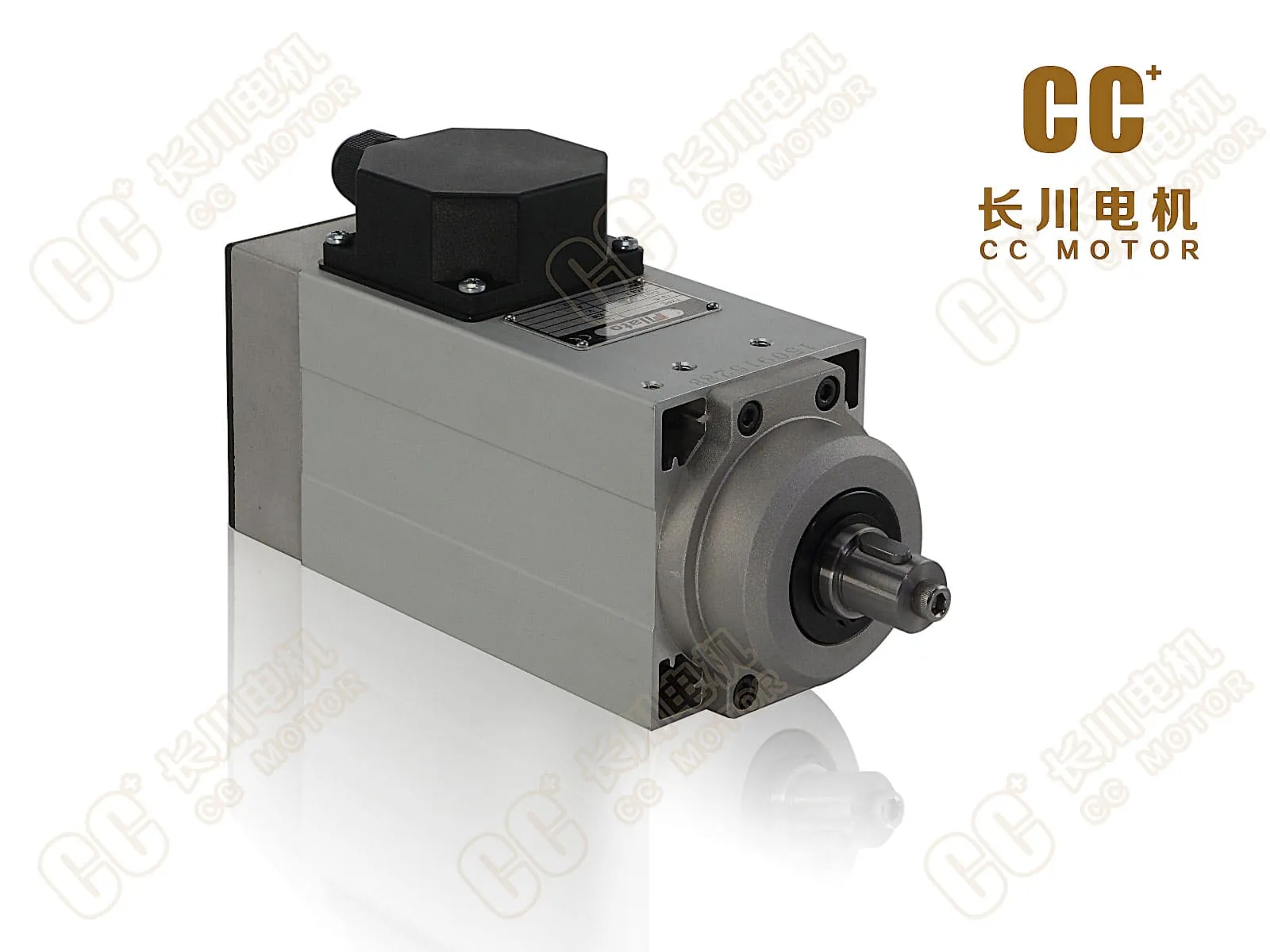

Rough Trimming Motor

- The edge bander spindle within this range is mainly used to realize the rough trimming function of the edge banding machine, remove the excess part after the edge banding is bonded to the board, ensure that the upper edge of the edge banding is flush with the surface of the board, and lay the foundation for the fine trimming process.

- After the edge bander strip is attached, the edge bander spindle used for rough trimming cuts off the reserved amount of the upper and lower edge banding strips to allow the fine trimming bits to work better. If the fine trimming bit is directly used, it will be very wasteful and shorten the service life of the knife. The fillet trimmed by the fine trimming bits may also be uneven with the board surface, affecting the aesthetics of the edge banding.

Fine Trimming Motor

- These types of edge bander spindle motors are used to finish panels. Trimming excess edges, chamfers, and fillets at the top and bottom are typical applications.

- Further trimming the edge of the edgebanding to make it completely flush with the surface of the panel eliminates any visible edgebanding marks and improves the aesthetics and quality of the final product. Ensures a natural, smooth transition from edgebanding to panel

Corner Trimming Motor

- The corner trimming motor is used for the precise processing of complex shapes and curved edges. Its main task is to ensure that the edge of the board fits perfectly with the edge banding, especially in the case of irregular or special shapes.

The pre-milling motor in the edge banding machine is a key component in the edge banding process. It is specially used to perform preliminary processing on the edge of the board to lay the foundation for the subsequent edge banding process.

Want to buy a new edge bander spindle to upgrade your edge bander for your panel furniture manufacturing business? You will have to face different types of choices on the market, such as fine trimming spindles, roughing trimming spindles, end trimming spindles, and many spindles from different brands have different features.

Although the working principle is the same, each machine’s experience may differ due to subtle design differences between manufacturers.

So, which one is more suitable for your needs and budget? This requires patient research and comparison. Here are the most popular edge bander spindles we have collected for small shops and industrial manufacturers in modern custom furniture manufacturing so you can make the best choice for your woodworking business.

We have divided edge banding machine spindles into three categories based on their different uses. You can choose according to your needs. If you don’t know how to choose, please contact us. We will have professionals answer your questions.

Learn More About Edge Bander Spindles

What Is Edge Bander And Its Spindle?

Edge banding machine is an automated equipment widely used in furniture manufacturing and woodworking industries, mainly used for edge banding of board edges. This equipment enhances the durability, beauty, and sealing of boards by gluing edge banding strips (such as PVC, veneer, plastic, etc.) to the edges of boards.

Suitable for the manufacture of panel furniture such as cabinets, wardrobes, office furniture, kitchen furniture, etc. Suitable for a variety of materials such as MDF (medium density fiberboard), blockboard, solid wood board, particleboard, polymer door panel, melamine board, and plywood.

The Role Of The Spindles Of Edge Bander

The Difference Between L And R In The Trimming Motor Of The Edge Banding Machine

The L and R in the spindle of the edge banding machine stand for the left and right, respectively. In daily life and various fields, L and R are widely used to indicate the left and right directions. L stands for the left, and R stands for the right. The L and R on the edge banding spindle also differ in function. L is usually used for trimming work on the left side, while R is used for trimming work on the right side.

Why Most Edge Banding Machine Spindles Use Air Cooling Instead of Water Cooling?

- Easy maintenance: The air-cooled system is relatively easy to maintain. It mainly relies on its fan for cooling, without the need to regularly replace water or use an industrial water cooler like a water-cooled spindle.

- Good heat dissipation: Although the heat dissipation effect of a water-cooled spindle may be better than that of an air-cooled spindle, for equipment such as edge banding machines that do not work continuously for a long time, the heat dissipation performance of an air-cooled spindle is usually sufficient to meet the needs.

- Easy to use: The water-cooled spindle must be connected to a water pump and pipe, especially when installed inside the edge banding machine. The space is very limited, and many people may find it troublesome. The air-cooled spindle does not have many usage problems and is more convenient to install and use.

The Adjustment Of The Edge Bander Spindle For End Trimming

Why Should You Choose RicoCNC?

Why Are Most Edge Banding Machines Equipped With Electro Spindles?

As a machine tool for fixed edge banding, the edge banding machine can be called a key tool for edge banding in the cabinet processing industry, home furnishing processing industry, furniture decoration industry, etc. However, users need to know that the core part of the edge banding machine is the edge banding machine motor. The high-quality edge banding machine spindle itself has incomparable benefits. So what are the advantages of a top edge banding machine spindle?

- Able to achieve high-efficiency and high-precision processing of edge banding machines

The high-quality edge banding machine spindle can achieve high-speed operation when the edge banding machine is working. The power of the edge banding machine spindle is actually very high. Coupled with the perfect match with the frequency converter, the entire edge banding machine structure can be simplified and the volume can be miniaturized, achieving high-speed rotation and high-precision processing.Long service life and complete functions

- Durability strength or the length of use time is also a point of concern for consumers or users. The edge banding machine motor is usually made of all-copper core material with good durability. The edge banding machine motor can even achieve automatic power-off operation in an emergency, which can also extend the actual service life of the edge banding machine motor to a certain extent. At the same time, the more functions the edge banding machine motor has, the more it can be recognized by users. For example, it has multiple functions such as gluing, grooving, finishing or polishing, which can make it more convenient for users to operate the edge banding machine.

Applicable Materials

Tips Before Ordering

How To Choose A Suitable Spindle For Edge Bander?

To make the produced wooden products more beautiful, they need to be edged. The edge banding machine is a woodworking machinery and equipment specially used for edge banding. However, many manufacturers are producing such edge banding equipment nowadays. How to purchase reliable edge banding machines from these manufacturers is a very learned thing. Let’s learn about it below. How do you choose edge banding machines when purchasing?

- Select by convenience of operation The development of industry allows wooden products to be mass-produced. More wooden products can be produced in a unit of time. If the operation process of the edge banding machine is very troublesome, it will delay production time and increase the number of products edged on the production line. In this way, it will not be conducive to improving the production efficiency of wooden products. For this reason, enterprises should select professional edge banding machines based on whether the operation process is convenient and simple.

- Select by stability The edge banding of wooden products is a later process. Whether the edge banding machine can operate stably and continuously determines the speed and quality of the edge banding. If the stability is not strong, the production will be wasted. Therefore, when purchasing edge banding equipment, enterprises should purchase equipment with stable working performance, which is conducive to the rapid and effective edge banding of manufactured wood products.

- Choose by bonding effect. The main function of the edge banding machine is to stick the edge strips to the side of the wood products. If the bonding effect is not good, it means that the edge strips are easy to fall off, which will affect the overall production quality of the wood products. Not only will it make consumers dissatisfied, but it will also adversely impact the manufacturer’s reputation. Therefore, when purchasing edge banding equipment, enterprises should choose according to the reliability of the edge strip bonding. If the manufacturer wants to make the wood products they manufacture get ideal edge banding treatment, on the one hand, they should learn more about where there are edge banding machines with good quality and low prices, and on the other hand, they should also understand how to choose the right edge banding machine. Only by considering the convenience of operation, stability, and firmness of bonding when selecting equipment can you choose edge banding equipment with a good edge banding effect.

Cost & Price

Notice When Ordering

Customer’s Guide

How To Keep The Edge Bander And Worker Safe

- Workers must undergo professional training and have particular mechanical operation experience.

- During operation, it is strictly forbidden to wear gloves to avoid being caught in the machine.

- It is strictly forbidden to put your hands or other objects into the working area of the edge bander to avoid accidental injuries.

- During operation, stay focused and avoid distraction.

- When replacing the edge strip, you must first turn off the power of the edge banding machine and wait for the machine to stop running entirely before operating.

- Regularly check the edge bander’s power cord and electrical equipment to ensure safety and reliability.

- If the edge banding machine is found to have abnormal phenomena or failures, it should be stopped immediately, and the maintenance personnel should be notified for inspection and repair.

How To Maintain Edge Bander And Its Spindle

Apply anti-rust oil to the spindle of the shaft regularly. Prevent the spindle from rusting