Introduction

CNC spindles and CNC spindle motors are integral to the operation of modern CNC machining centers. Their performance is pivotal to the quality and efficiency of machining processes. This article delves into the intricate structure and functioning of these components, highlighting the technologies that enhance their capabilities and ensure precision and longevity in use.

What Kind of Component is a CNC Spindle?

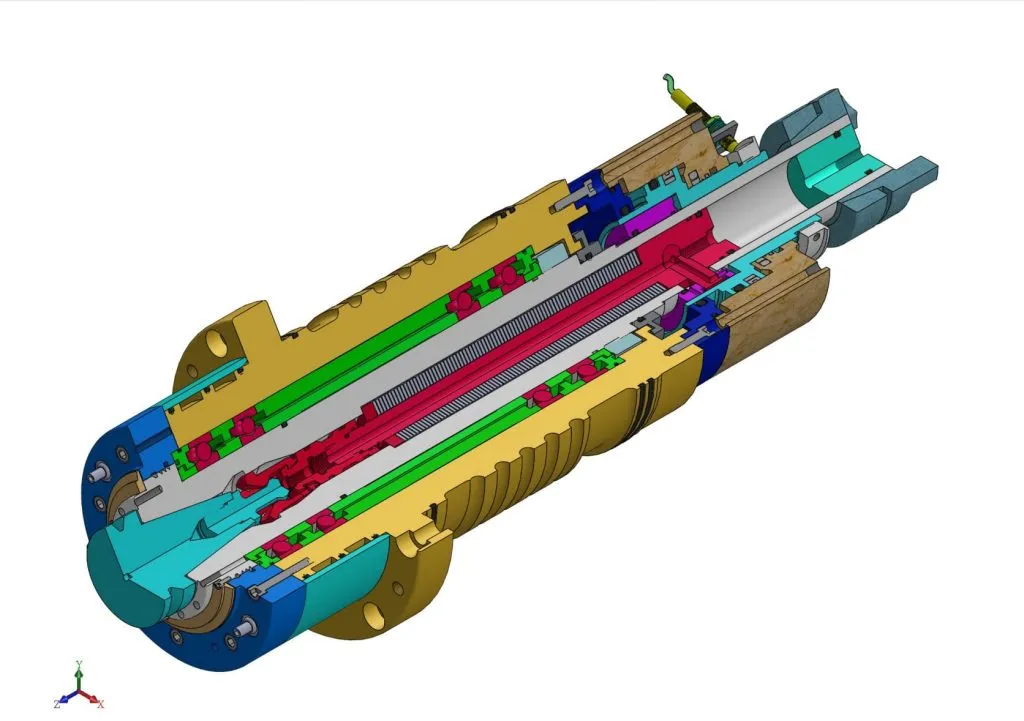

CNC spindles, including electric spindles, are complex components that extend beyond a simple rotating axis. They encompass the spindle itself and various accessories such as high-frequency converters, lubricators, cooling systems, encoders, and tool changers. The electric spindle, as the core, features a hollow motor rotor directly assembled on the spindle, simplifying the structure and boosting energy efficiency.

The technology of CNC Spindle Integration

The seamless operation of CNC spindles is contingent upon the integration of advanced technologies. High-speed bearing technology, for instance, utilizes composite ceramic bearings that outperform traditional steel bearings in wear and heat resistance. Cooling and lubrication technologies are also essential, preventing overheating and maintaining spindle integrity during high-speed operations.

Working Principle of CNC High-Speed Electro Spindles

Understanding the working principle of CNC high-speed electric spindles is crucial. They operate based on fundamental principles, such as using micro servo motors as closed-loop feedback systems and the internal structure of high-speed motors, which includes components like DC motors, gear sets, potentiometers, and electronic control boards.

Principle 1: Micro Servo Motor as a Typical Closed-Loop Feedback System

The micro servo motor exemplifies a closed-loop feedback system, where the motor drives a reduction gear set, and a linear potentiometer detects position, feeding back to the control circuit board for precise adjustments and positioning.

Principle 2: Internal Structure of CNC High-Speed Motor

The internal structure of a high-speed motor is designed for efficiency, with components working in tandem to adjust output characteristics according to processing demands. This design ensures the motor can handle varying loads and speeds, adapting to heavy-duty and high-speed precision machining tasks.

Conclusion Grasping the intricacies of CNC spindles and their motors is essential for optimizing the machining process. These components, through the integration of sophisticated technologies, not only enhance efficiency but also prolong equipment life. They are indispensable for both high-precision and heavy-load machining applications.

Summary FAQ Based on the Article

- CNC Spindles and CNC Spindle Motors: These are comprehensive components that include the spindle and its accessories, with the spindle motor being the core that directly drives rotation.

- Technologies Integrated in CNC Spindles: They include high-speed bearing technology, advanced bearing types like electromagnetic suspension or hydrostatic bearings, and cooling and lubrication systems for improved performance and durability.

- Micro Servo Motor Operation: As closed-loop feedback systems, they use potentiometers for position detection and control circuit boards for feedback, achieving precise positioning and operation.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.