Favoring Your CNC Spindle Motor: A Comprehensive Guide to Optimal Performance

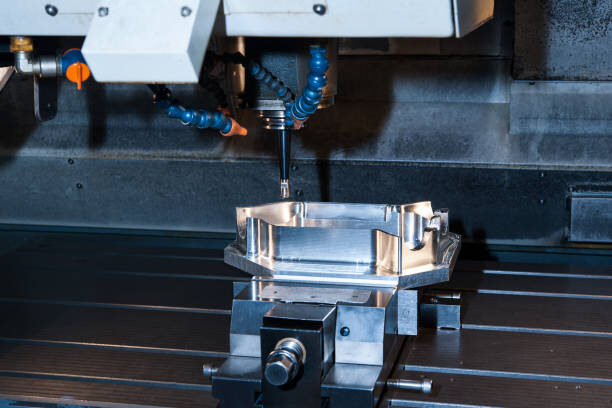

Are you looking to get the most out of your CNC spindle motor? Whether you’re a hobbyist or a professional machinist, understanding how to properly favor and maintain your CNC spindle motor is crucial for achieving precision cuts and extending the life of your equipment. This guide will walk you through the essential steps to keep your spindle motor running at peak performance, ensuring your CNC machine delivers consistent, high-quality results.

What is a CNC Spindle Motor and Why is it Important?

A CNC spindle motor is the heart of your CNC machine, responsible for rotating the cutting tool at high speeds. It’s a critical component that directly affects the quality of your cuts, the efficiency of your operations, and the overall lifespan of your CNC setup.Key points about CNC spindle motors:

- They come in various types, including air-cooled and water-cooled spindles

- Power ratings typically range from 1.5kW to 2.2kW for hobby and small professional setups

- Proper maintenance is crucial for optimal performance and longevity

Understanding your spindle motor is the first step in learning how to favor it for best results.

How Do You Choose the Right CNC Spindle Motor?

Selecting the appropriate spindle motor for your CNC machine is crucial. Consider these factors:

- Power requirements (e.g., 1.5kW, 2.2kW)

- Cooling method (air-cooled vs. water-cooled spindle)

- Speed range and torque

- Collet size compatibility

- Noise levels

For precision work, a water-cooled spindle often provides better temperature stability and quieter operation compared to air-cooled alternatives.

What Are the Benefits of Water-Cooled vs. Air-Cooled Spindles?

Both water-cooled and air-cooled spindles have their place in CNC machining. Here’s a quick comparison:Water-Cooled Spindles:

- Better heat dissipation

- Quieter operation

- More consistent performance over long periods

- Ideal for high-precision work

Air-Cooled Spindles:

- Simpler setup with no coolant system required

- Generally more affordable

- Suitable for lighter-duty applications

- Easier maintenance

Your choice will depend on your specific needs and budget. For many professional setups, a water-cooled spindle is often the preferred choice due to its superior cooling capabilities.

How Do You Properly Install a CNC Spindle Motor?

Correct installation is crucial for optimal spindle performance. Follow these steps:

- Ensure proper alignment with the machine’s axis

- Securely mount the spindle to prevent vibration

- Connect cooling systems (for water-cooled spindles)

- Properly wire the motor to the controller

- Test run at various speeds to check for any issues

For complex setups, consider using a CNC router with a pre-installed spindle to simplify the process.

What Maintenance Routines Should You Follow?

Regular maintenance is key to favoring your CNC spindle motor. Here’s a basic routine:

- Daily: Check for unusual noises or vibrations

- Weekly: Clean the spindle and check collet condition

- Monthly: Lubricate bearings (if applicable)

- Quarterly: Inspect electrical connections and cooling system

For water-cooled spindles, regularly check the coolant levels and quality. Clean or replace filters as needed to ensure optimal cooling performance.

How Can You Optimize Spindle Speed and Feed Rates?

Optimizing your spindle speed and feed rates is crucial for both cut quality and spindle longevity. Consider these tips:

- Match spindle speed to the material and cutting tool

- Start with conservative feed rates and gradually increase

- Monitor cut quality and adjust as needed

- Use a spindle speed controller for precise adjustments

Remember, the right balance between speed and feed rate will result in cleaner cuts and reduced wear on your spindle.

What Are Common Issues with CNC Spindle Motors and How to Solve Them?

Even with proper maintenance, issues can arise. Here are some common problems and solutions:

- Overheating: Check cooling system, reduce workload

- Unusual noise: Inspect bearings, check for loose components

- Poor cut quality: Adjust speed/feed rates, check tool sharpness

- Vibration: Ensure proper mounting, check for worn bearings

If problems persist, consult with a professional or consider upgrading to a more robust spindle motor.

How Do You Upgrade Your CNC Spindle Motor?

Upgrading your spindle can significantly improve your CNC machine’s capabilities. Consider these factors:

- Compatibility with your current setup

- Power requirements and available electrical supply

- Cooling method (air vs. water)

- Tooling compatibility (collet size)

When upgrading, a CNC spindle motor kit can provide a comprehensive solution, ensuring all components work together seamlessly.

What Safety Precautions Should You Take When Working with CNC Spindle Motors?

Safety should always be a top priority. Follow these guidelines:

- Always wear appropriate personal protective equipment (PPE)

- Ensure proper grounding of electrical components

- Never touch the spindle or workpiece while the machine is running

- Regularly inspect safety features like emergency stop buttons

- Keep your work area clean and free of debris

Remember, a safe work environment is crucial for both personal safety and optimal machine performance.

How Can You Troubleshoot Spindle Motor Issues?

When problems arise, systematic troubleshooting can help identify the cause:

- Start with visual inspection for obvious issues

- Check electrical connections and power supply

- Inspect cooling system components

- Test spindle at various speeds

- Consult machine documentation or manufacturer support

For complex issues, don’t hesitate to seek professional help to avoid potentially costly damage to your spindle or CNC machine.In conclusion, favoring your CNC spindle motor involves a combination of proper selection, installation, maintenance, and operation. By following these guidelines, you can ensure optimal performance and longevity of your CNC setup.Key takeaways:

- Choose the right spindle motor for your needs (power, cooling method)

- Install correctly to prevent vibration and ensure proper alignment

- Follow regular maintenance routines

- Optimize spindle speed and feed rates for each job

- Address issues promptly and safely

- Consider upgrades when necessary to improve capabilities

Remember, a well-maintained spindle motor is the key to precise, efficient CNC machining. With proper care and attention, your CNC spindle motor will serve you well for years to come.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.