Introduction

Spindle speed plays a pivotal role in CNC machining, affecting everything from tool life to surface finish and cutting efficiency. If you’re operating a CNC machine, especially one with a cnc spindle motor, understanding how to calculate the spindle speed is essential for optimizing performance. Whether you’re using a cnc router spindle motor or a multi spindle cnc machine, having the correct spindle speed can drastically impact machining accuracy and the final product quality.

This article will explore the factors affecting spindle speed, how to calculate it, and how to optimize it for different machining operations. We’ll break down complex concepts into easy-to-follow steps, so you can improve your machine’s efficiency, reduce tool wear, and increase output. By the end, you’ll have a comprehensive understanding of how to calculate spindle speed for your CNC machine and apply this knowledge to improve your workflow.

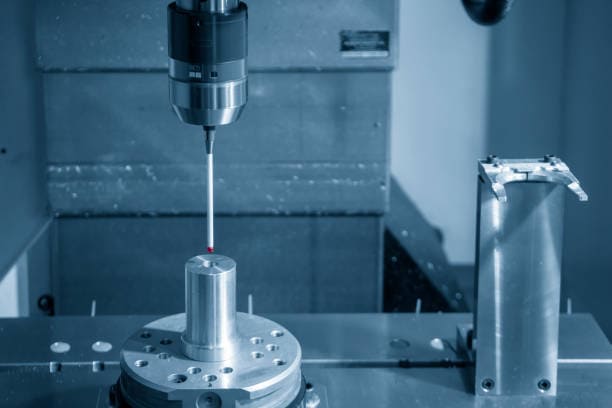

Understanding Spindle Speed in CNC Machining

The Importance of Spindle Speed for Precision and Efficiency

Spindle speed, typically measured in revolutions per minute (RPM), refers to how fast the cnc spindle rotates the cutting tool or workpiece. It directly impacts the cutting efficiency, tool wear, and surface finish of the material being machined. Operating at the optimal spindle speed ensures that the material is removed efficiently while minimizing tool wear, which is especially important when using a cnc router spindle for various applications.

Basic Concepts: RPM, Feed Rate, and Cutting Speed

Before diving into the specifics of spindle speed calculation, it’s essential to understand three interrelated concepts: RPM, feed rate, and cutting speed. RPM is the speed at which the spindle rotates, feed rate is the speed at which the tool advances into the material, and cutting speed is the speed of the cutting edge as it makes contact with the workpiece. Achieving the correct balance between these factors is crucial for efficient machining, especially when working with a spindle for cnc.

The Formula for Calculating Spindle Speed

Formula for Spindle Speed Calculation

The formula for calculating spindle speed is:

Spindle Speed (RPM) = (Cutting Speed × 1000) ÷ (π × Tool Diameter)

Where:

- Cutting Speed is the speed of the cutting edge, typically measured in meters per minute (m/min).

- Tool Diameter is the diameter of the cutting tool or workpiece in millimeters (mm).

This formula helps you calculate the correct spindle speed for various materials and tools, ensuring a smooth and efficient cutting process.

Factors Affecting Spindle Speed Selection

Variables Involved in Spindle Speed Calculation

Several variables influence spindle speed calculation, including the material of the workpiece, the diameter of the cutting tool, and the type of machining operation (e.g., milling, drilling, turning). Each material has a recommended cutting speed, which must be factored into the calculation to avoid excessive tool wear or poor-quality surface finishes when using cnc spindles.

Material Considerations and Tooling Specifications

Different materials require different spindle speeds. For instance, softer materials like aluminum require higher spindle speeds, while harder materials like steel need slower speeds to avoid damaging the tool. Additionally, the type and size of the tool also affect the optimal spindle speed. Tools with larger diameters need lower RPMs to maintain the correct cutting speed.

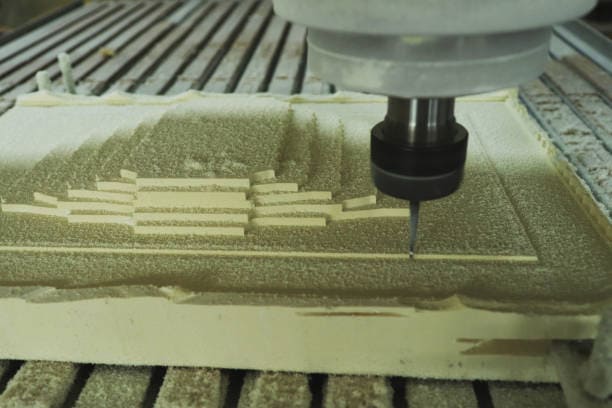

Optimizing Spindle Speed for Different CNC Operations

Drilling, Milling, and Turning: Adjustments for Each Operation

Each type of CNC operation requires different spindle speed settings. For example, turning operations, where the workpiece rotates, may need lower RPMs compared to milling, where the tool itself rotates. Drilling operations typically fall between the two, and the diameter of the drill bit also plays a critical role in setting the correct speed.

Machine Capabilities and Limitations

It’s essential to consider the capabilities of your multi spindle cnc machine when setting spindle speeds. Exceeding the recommended RPMs can lead to machine failure or reduced tool life. Always check the manufacturer’s guidelines for maximum and minimum spindle speeds for your machine model to prevent issues.

Factors Influencing Spindle Speed Calculation

Material Type and Tool Diameter

Material type and tool diameter are the two most significant factors influencing spindle speed. Larger tool diameters require slower spindle speeds, while smaller tools can handle higher RPMs. Similarly, harder materials like titanium require lower spindle speeds, while softer materials like plastic can be machined at higher speeds.

Cutting Speed and Feed Rate

Cutting speed and feed rate work in tandem with spindle speed to ensure optimal machining performance. The feed rate must be adjusted alongside spindle speed to ensure that the cutting process remains efficient and doesn’t damage the tool. A faster feed rate may require a slower spindle speed, depending on the material and tool being used.

Step-by-Step Guide to Calculating Spindle Speed

Step-by-Step Guide to the Calculation Process

To calculate the spindle speed for a CNC machine, follow these steps:

- Determine the recommended cutting speed for the material you’re working with. This information is usually available in machining handbooks or from the tool manufacturer.

- Measure the diameter of the tool or workpiece.

- Plug the values into the spindle speed formula: Spindle Speed (RPM) = (Cutting Speed × 1000) ÷ (π × Tool Diameter).

- Adjust the spindle speed based on the specific operation (drilling, milling, turning).

- Run a test cut to verify that the speed is appropriate for the material and tool.

Optimizing Spindle Speed for Efficiency

Tips for Adjusting Spindle Speed

Once you have calculated the spindle speed, consider making adjustments based on the specific material and operation. For example, if you’re working with aluminum, you may need to increase the speed compared to steel. Always start with a conservative RPM and adjust upward if the material allows.

Examples of Spindle Speed Calculations

For example, if you’re machining aluminum with a cutting speed of 300 m/min and using a 10mm tool diameter, the spindle speed would be:

Spindle Speed = (300 × 1000) ÷ (π × 10) ≈ 9,549 RPM

If you’re working with steel, with a cutting speed of 80 m/min and the same tool diameter, the spindle speed would be:

Spindle Speed = (80 × 1000) ÷ (π × 10) ≈ 2,546 RPM

Conclusion

Calculating spindle speed is a fundamental aspect of CNC machining that directly affects performance, tool life, and the quality of the final product. By understanding how to apply the spindle speed formula and adjust for different materials and tools, you can optimize your CNC machine’s efficiency, whether you’re using a cnc router spindle or a multi spindle cnc machine. Always consider factors like material type, tool diameter, and the specific machining operation when determining spindle speed.

FAQ

Can spindle speed affect the quality of the finished product?

Yes, incorrect spindle speeds can result in poor surface finish, excessive tool wear, or even material damage. Properly setting spindle speed ensures smoother cuts and higher-quality finishes.

How do changes in material affect spindle speed settings?

Different materials require different spindle speeds. Softer materials like aluminum allow for higher spindle speeds, while harder materials like steel need lower speeds to avoid damaging the tool or workpiece.

Can I use the same spindle speed for different materials?

No, each material has its own recommended spindle speed. Using the same speed for different materials can lead to poor performance and potentially damage your tools or the workpiece.

Key Takeaways:

- Spindle speed is critical for efficient CNC machining and affects the quality of the finished product.

- Use the spindle speed formula to calculate RPM based on the cutting speed and tool diameter.

- Always consider material properties and tool diameter when determining the correct spindle speed.

- Adjust spindle speed for different CNC operations like drilling, milling, or turning.

- Test and adjust the spindle speed to optimize efficiency and prevent tool damage.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.