Summary:

Locking the spindle on a CNC mill is a vital step in ensuring both safety and precision during operations like tool changes or routine maintenance. When the spindle is locked correctly, it prevents unwanted movement, guaranteeing the accuracy of cuts and protecting both the operator and the machine. This article explores the spindle locking process in detail, explains its importance, and offers practical advice on performing this task safely and efficiently. By mastering spindle locking techniques, operators can optimize the performance of their CNC mills.

Introduction

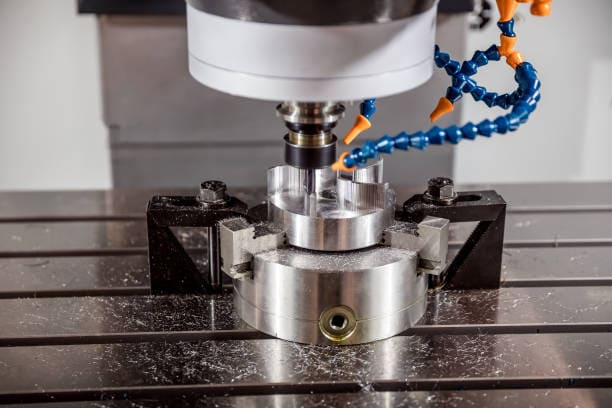

CNC mills are highly complex machines that rely on precise and well-coordinated mechanisms to perform accurately. One of the most essential features of these machines is the spindle, which holds and rotates the cutting tool. To ensure safety during operations like tool changes or calibration, the spindle often needs to be locked in place. Knowing how to lock the spindle effectively is a critical skill for any CNC operator, as improper handling can lead to machine damage or operator injury.

Locking a CNC spindle is not only about convenience; it’s an essential safety measure, particularly when working with high-speed CNC spindle motors. A locked spindle ensures the tool remains in place during setup, protecting against accidental movements. The process is straightforward but must be performed correctly to ensure both the safety of the operator and the longevity of the machine.

Understanding the CNC Mill Spindle Locking Mechanism

The spindle locking mechanism in a CNC machine is designed to immobilize the spindle during non-cutting operations such as tool changes, maintenance, or calibration. This prevents the spindle from rotating, ensuring that tools can be safely installed or removed without risk. Depending on the type of CNC machine, the spindle lock can be a manual or automatic feature, activated via a button, lever, or control panel option.

In most CNC mills, including those with multi-spindle CNC machines, the spindle motor drives the cutting tool’s rotation. When the spindle lock is engaged, it physically or electronically prevents the motor from turning the spindle, offering protection from unintended movements. This locking process is crucial for tasks that require precision alignment, as any slight rotation can compromise the quality of the cut or cause damage to the tool.

The Importance of Spindle Locking in CNC Operations

Spindle locking is not just about stopping the spindle’s rotation; it plays a key role in ensuring the overall safety and accuracy of CNC operations. When the spindle is locked, it provides a stable platform for tool changes, preventing accidents caused by unexpected tool shifts. This is particularly important when working with a CNC router spindle or a spindle for CNC machines that operate at high speeds.

Moreover, spindle locking enhances the precision of tool alignment. Without it, even the slightest movement of the spindle can result in a misalignment of the cutting tool, which could affect the quality of the workpiece. Properly locking the spindle ensures that the tool is correctly positioned, maintaining the integrity of the CNC milling process.

How Spindle Locking Enhances Safety and Precision

One of the primary benefits of spindle locking is its contribution to operator safety. When the spindle is locked, the risk of injury from a spinning tool is eliminated. This is especially important during tool changes, where the operator must work closely with the cutting tool and spindle. For CNC router spindle motors, which can rotate at extremely high speeds, locking the spindle ensures a safe and stable environment for the operator.

Additionally, spindle locking plays a crucial role in maintaining the precision of CNC operations. By immobilizing the spindle, operators can ensure that tools are perfectly aligned, reducing the likelihood of errors. This is particularly important in industries where accuracy is paramount, such as in aerospace or automotive manufacturing.

Step-by-Step Guide to Locking a Spindle on a CNC Mill

Locking the spindle on a CNC mill is a straightforward process, but it requires careful attention to detail. Whether you’re working with a CNC spindle motor or a multi-spindle CNC machine, following the proper steps ensures that the spindle is securely locked, preventing any unwanted movement.

Preparing Your CNC Mill for Spindle Locking

Before attempting to lock the spindle, it’s important to ensure that the machine is properly prepared. Start by powering down the CNC mill and allowing the spindle to come to a complete stop. This is especially important for machines with high-speed CNC router spindle motors, as attempting to lock the spindle while it’s still spinning can cause damage to the machine or the tool.

- Ensure that the machine is powered down and the spindle has come to a complete stop.

- Check the spindle and the surrounding area for any obstructions or debris that could interfere with the locking mechanism.

- Consult the machine’s manual for specific instructions regarding the spindle lock mechanism on your CNC model.

The Actual Process of Locking the Spindle

Depending on the CNC mill model, the spindle lock can be engaged manually or electronically. For manual locks, you may need to rotate the spindle until it reaches a locking position, then secure it with a lever or button. For electronic locks, the process is simpler—typically involving pressing a button or selecting an option from the machine’s control panel.

Here’s a general guide to locking the spindle on a CNC mill:

- Locate the spindle lock mechanism on your machine. This may be a physical button, lever, or an electronic control.

- If using a manual lock, rotate the spindle until it clicks into place, then engage the lock by pressing the lever or button.

- If using an electronic lock, simply press the spindle lock button or select the appropriate option from the control panel.

- Once the lock is engaged, gently try to rotate the spindle by hand to ensure that it is securely locked.

The Process of Locking a Spindle on a CNC Mill

While the spindle locking process is relatively simple, it’s important to follow the steps carefully to avoid damaging the spindle or the machine. On most CNC mills, the spindle lock is engaged manually or electronically, depending on the model. For CNC router spindle motors, the process involves stopping the spindle and then engaging the locking mechanism to prevent further rotation.

Tools Required for the Locking Process

In most cases, no additional tools are needed to lock the spindle, as the lock is typically built into the CNC machine. However, some models may require a wrench or other tool to manually engage the spindle lock. Always refer to your machine’s manual to determine if any specific tools are needed for the locking process.

Safety Precautions and Best Practices

Safety is a critical consideration when working with CNC mills, particularly during tasks like spindle locking. By following safety guidelines and best practices, operators can ensure that they lock and unlock the spindle without risking injury or damaging the machine. Here are some key safety tips to keep in mind when locking the spindle on a CNC mill.

Importance of Safety When Working with CNC Mills

Locking the spindle during tool changes and maintenance tasks reduces the risk of injury by ensuring that the cutting tool remains stationary. The high speeds at which CNC router spindle motors operate make it essential to follow proper safety procedures, as even a small mistake can result in serious accidents.

Tips for Ensuring a Safe Locking and Unlocking Procedure

- Always wait for the spindle to come to a complete stop before engaging the spindle lock.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, when working near the spindle.

- Make sure the spindle lock is fully engaged before attempting to change tools or perform maintenance tasks.

- If your machine has a manual spindle lock, be sure to follow the manufacturer’s instructions carefully to avoid damaging the locking mechanism.

Troubleshooting Common Issues

Even with proper care and attention, you may encounter problems when locking or unlocking the spindle on a CNC mill. Understanding how to troubleshoot these issues will help you resolve them quickly, minimizing downtime and keeping your machine running smoothly. Here are some common issues and solutions related to spindle locking.

Dealing with a Stuck Spindle

A common issue encountered during spindle locking is a spindle that becomes stuck and fails to lock or unlock properly. This can occur due to debris in the locking mechanism, misalignment, or wear on the spindle components. Here’s how to troubleshoot a stuck spindle:

- Inspect the spindle and locking mechanism for debris or damage. If debris is present, clean the area thoroughly before attempting to lock the spindle again.

- If the spindle lock is worn or damaged, consult your machine’s manual for instructions on replacing the faulty parts.

- If the spindle remains stuck after cleaning and inspection, contact a professional technician for assistance.

Preventative Maintenance to Avoid Locking Problems

Regular maintenance of your CNC spindle motor and locking mechanism is essential to preventing issues with spindle locking. Lubricating the spindle and keeping it free of debris will help ensure smooth operation. Additionally, regularly inspecting the spindle lock for signs of wear or damage will allow you to address potential problems before they affect the machine’s performance.

Conclusion

Locking the spindle on a CNC mill is a crucial process that ensures both safety and precision during operations like tool changes, maintenance, and calibration. By understanding how the spindle locking mechanism works and following proper procedures, operators can optimize the performance of their CNC machines while reducing the risk of accidents and errors. Whether working with a CNC router spindle or a multi-spindle CNC machine, mastering the process of locking the spindle is an essential skill for any CNC operator.

Key Takeaways:

- Spindle locking is essential for safety during tool changes and maintenance tasks.

- Always follow the machine’s manual for specific instructions on locking and unlocking the spindle.

- Regular maintenance of the spindle and locking mechanism will help avoid issues.

- When in doubt, consult your machine’s troubleshooting guide to resolve spindle lock problems.

FAQ

What Makes a Spindle Lock Mechanism Fail?

Several factors can cause a spindle lock mechanism to fail, including debris in the locking system, worn-out components, or misalignment. Regular cleaning and maintenance can help prevent such issues.

What makes a spindle lock fail to engage on a CNC mill?

The most common reasons for a spindle lock failing to engage include wear on the locking mechanism, insufficient lubrication, or debris obstructing the spindle lock components. Regular inspection and cleaning can prevent this issue.

Can I manually lock the spindle on any CNC mill model?

Most CNC mills have a built-in spindle lock mechanism, but the method of locking can vary between models. Some may require manual locking, while others use electronic locks that can be engaged through the machine’s control panel. Always refer to your specific machine’s manual for detailed instructions.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.