How Does CNC Milling Work?

CNC milling is a fascinating process that has revolutionized the manufacturing industry. This advanced machining technique allows for the creation of complex parts with incredible precision and efficiency. In this article, we’ll dive deep into the world of CNC milling, exploring its inner workings, applications, and the technology that makes it all possible.

The Basics of CNC Milling

CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece. The term “CNC” stands for Computer Numerical Control, which refers to the automated control of machining tools using pre-programmed computer software.

At its core, CNC milling works by:

- Starting with a solid block of material (often metal, but can be plastic, wood, or other materials)

- Using rotating cutting tools to remove material

- Following a precise set of instructions (G-code) to create the desired shape

This process allows for the creation of complex 3D shapes with high accuracy and repeatability.

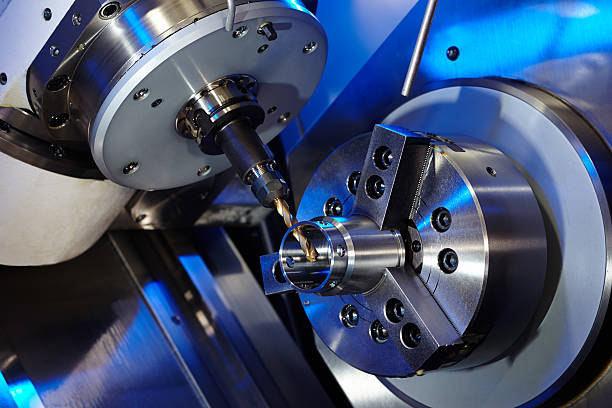

The CNC Milling Machine: Anatomy of Precision

To understand how CNC milling works, it’s essential to familiarize yourself with the key components of a CNC milling machine:

- Machine Base: Provides stability and supports all other components

- Work Table: Holds the workpiece securely during machining

- Spindle: Rotates the cutting tool at high speeds

- Cutting Tools: Various end mills, drills, and other tools for material removal

- Tool Changer: Automatically swaps cutting tools as needed

- Axes: Allow for movement in multiple directions (typically 3 to 5 axes)

- Motors and Drives: Control the movement of the axes

- Control Panel: Interface for operating the machine

- Coolant System: Manages heat and removes chips during cutting

One of the most critical components is the spindle, which holds and rotates the cutting tool. High-quality CNC spindles are essential for achieving precise and efficient milling operations.

A 24000RPM 3KW ER20 Water-Cooling Spindle, crucial for precise CNC milling operations

The CNC Milling Process: From Design to Finished Part

Let’s walk through the step-by-step process of how CNC milling turns a digital design into a physical part:

- Design: Create a 3D model using CAD (Computer-Aided Design) software

- CAM Programming: Convert the 3D model into a set of machining instructions (G-code)

- Machine Setup: Load the workpiece and cutting tools into the CNC machine

- Program Upload: Transfer the G-code to the CNC machine’s control system

- Machining: The CNC mill executes the program, removing material to create the part

- Finishing: Perform any necessary post-processing (e.g., deburring, polishing)

- Inspection: Verify the part’s dimensions and quality

Throughout this process, the CNC machine’s control system coordinates the movement of the cutting tool relative to the workpiece, following the programmed instructions with extreme precision.

Types of CNC Milling Operations

CNC milling machines can perform a wide variety of cutting operations, including:

- Face Milling: Cutting flat surfaces

- Shoulder Milling: Creating stepped features

- Slot Milling: Cutting channels or grooves

- Plunge Milling: Vertical cutting into the material

- Contour Milling: Cutting complex 3D shapes

- Drill and Tap: Creating and threading holes

Each of these operations requires specific cutting tools and machining strategies to achieve the desired results.

The Power of Multi-Axis Milling

While traditional milling machines operate on three axes (X, Y, and Z), modern CNC milling centers can have up to 5 axes of movement. This additional flexibility allows for:

- Machining complex geometries in a single setup

- Reducing the need for multiple setups and fixtures

- Improving surface finish and accuracy

- Shortening overall machining time

Advanced CNC spindle motors are crucial for multi-axis milling, providing the power and precision needed for these complex operations.

A high-performance 24000RPM 5.5KW ER25 Water-Cooling Spindle, ideal for multi-axis milling

Materials and Cutting Tools: A Perfect Match

CNC milling can work with a wide range of materials, including:

- Metals (aluminum, steel, titanium, etc.)

- Plastics

- Wood

- Composites

Selecting the right cutting tool for the material and operation is crucial. Factors to consider include:

- Tool material (e.g., high-speed steel, carbide)

- Number of flutes

- Coating

- Geometry

For example, a 2.2KW ER20 Air-Cooled Spindle might be ideal for milling aluminum, while a more powerful water-cooled spindle could be better suited for tougher materials like steel or titanium.

The Role of CAD/CAM Software

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software play a crucial role in CNC milling:

- CAD: Used to create detailed 3D models of the parts to be machined

- CAM: Generates the toolpaths and G-code that control the CNC machine

Modern CAD/CAM software offers advanced features like:

- Simulation of machining processes

- Collision detection

- Automatic feature recognition

- Optimized toolpath generation

These tools help ensure efficient and error-free machining operations.

Precision and Accuracy in CNC Milling

One of the key advantages of CNC milling is its ability to produce parts with extremely tight tolerances. Factors that contribute to this precision include:

- Rigid machine construction

- High-quality spindles and cutting tools

- Advanced control systems

- Environmental controls (temperature, vibration)

Typical tolerances for CNC milled parts can be as tight as ±0.0005 inches (0.0127 mm) or even better in some cases.

Applications of CNC Milling

CNC milling finds applications across a wide range of industries:

- Aerospace: Complex components for aircraft and spacecraft

- Automotive: Engine parts, molds for body panels

- Medical: Implants, surgical instruments

- Electronics: Housings, heat sinks

- Mold and Die: Creating tools for mass production

- Prototyping: Rapid creation of concept models and functional prototypes

The versatility of CNC milling makes it an invaluable technology in modern manufacturing.

Advancements in CNC Milling Technology

The field of CNC milling is constantly evolving. Some recent advancements include:

- High-Speed Machining: Faster spindle speeds and optimized toolpaths for increased productivity

- Hybrid Manufacturing: Combining additive and subtractive processes in a single machine

- Smart Sensors: Real-time monitoring of tool wear and machine conditions

- AI and Machine Learning: Optimizing machining parameters and predicting maintenance needs

- Improved User Interfaces: Making CNC programming more intuitive and accessible

These innovations are pushing the boundaries of what’s possible with CNC milling.

The Importance of Proper Machine Setup

Achieving optimal results with CNC milling requires careful attention to machine setup:

- Workpiece Fixturing: Securely holding the material to prevent movement during machining

- Tool Selection and Setup: Choosing the right tools and ensuring proper installation

- Machine Calibration: Regular checks to maintain accuracy

- Environmental Control: Managing temperature and vibration in the workspace

Proper setup is crucial for achieving the desired accuracy and surface finish in CNC milling operations.

Challenges and Solutions in CNC Milling

While CNC milling is a powerful technology, it does come with some challenges:

- Tool Wear: Regular monitoring and replacement of cutting tools is necessary

- Heat Management: Proper cooling strategies are essential to maintain accuracy

- Chip Evacuation: Efficient removal of material chips to prevent re-cutting

- Programming Complexity: Generating optimal toolpaths for complex parts can be challenging

Solutions to these challenges often involve a combination of advanced tooling, sophisticated software, and skilled operators.

The Future of CNC Milling

As we look to the future, several trends are shaping the evolution of CNC milling:

- Integration with IoT: Connecting machines for improved monitoring and data analysis

- Sustainable Manufacturing: Developing more energy-efficient machines and processes

- Automation and Robotics: Increasing lights-out manufacturing capabilities

- Advanced Materials: Developing new cutting tools and strategies for exotic materials

These developments promise to make CNC milling even more powerful and versatile in the years to come.

Comparing CNC Milling to Other Manufacturing Processes

To better understand the strengths of CNC milling, let’s compare it to some other common manufacturing processes:

| Process | Advantages | Limitations |

|---|---|---|

| CNC Milling | High precision, complex geometries, wide range of materials | Higher initial cost, material waste |

| 3D Printing | Fast prototyping, complex internal structures | Limited material options, lower strength |

| Casting | Good for high volume production, low per-part cost | Limited complexity, lower precision |

| Forging | High strength parts, good for simple shapes | Limited complexity, high tooling costs |

CNC milling often strikes a balance between precision, flexibility, and the ability to work with a wide range of materials.

Best Practices for CNC Milling

To achieve optimal results in CNC milling, consider these best practices:

- Proper Planning: Thoroughly analyze the part design and develop an efficient machining strategy

- Tool Selection: Choose high-quality cutting tools appropriate for the material and operation

- Optimize Cutting Parameters: Fine-tune speeds, feeds, and depths of cut for best results

- Regular Maintenance: Keep the machine clean and well-maintained for consistent performance

- Continuous Learning: Stay updated on new technologies and techniques in the field

By following these practices, you can maximize the efficiency and quality of your CNC milling operations.

FAQs About CNC Milling

1. What is the difference between CNC milling and CNC turning?

CNC milling uses rotating cutting tools to remove material from a stationary workpiece, while CNC turning rotates the workpiece against a stationary cutting tool. Milling is better for complex shapes and features, while turning is ideal for cylindrical parts.

2. How accurate is CNC milling?

CNC milling can achieve very high accuracy, typically within ±0.0005 inches (0.0127 mm) or better. The exact accuracy depends on factors like machine quality, tooling, and material properties.

3. What materials can be machined using CNC milling?

CNC milling can work with a wide range of materials, including metals (aluminum, steel, titanium), plastics, wood, composites, and even some ceramics. The choice of material affects the selection of cutting tools and machining parameters.

4. How long does a typical CNC milling operation take?

The time required for a CNC milling operation can vary greatly depending on the part complexity, material, and desired surface finish. Simple parts might be completed in minutes, while complex components could take hours or even days.

5. Is CNC milling suitable for small-scale or prototype production?

Yes, CNC milling is excellent for prototyping and small-scale production. Its flexibility allows for quick design iterations and the ability to produce functional parts in final materials without the need for expensive tooling.

Conclusion

CNC milling is a powerful and versatile manufacturing process that has transformed the way we create complex parts across numerous industries. By leveraging computer control, advanced tooling, and precise machinery, CNC milling enables the production of highly accurate components with incredible efficiency.

From the initial CAD design to the final machined part, CNC milling combines cutting-edge technology with time-honored machining principles. The ability to work with a wide range of materials, create complex geometries, and maintain tight tolerances makes CNC milling an indispensable tool in modern manufacturing.

As technology continues to advance, we can expect CNC milling to become even more powerful, efficient, and accessible. Whether you’re a seasoned machinist or just beginning to explore the world of CNC, understanding how CNC milling works is key to unlocking its full potential.

By embracing best practices, staying informed about new developments, and investing in quality equipment like high-performance spindle motors, you can harness the power of CNC milling to bring your ideas to life with unprecedented precision and efficiency.

A 24000RPM 1.5KW ER16 Water-Cooled Spindle, essential for precision CNC milling operations

The world of CNC milling is vast and exciting, offering endless possibilities for innovation and creation. As we look to the future, it’s clear that this technology will continue to play a crucial role in shaping the products and components that drive our modern world.