How Fast Does a CNC Machine Work?

The speed at which a CNC (Computer Numerical Control) machine works is a crucial factor in modern manufacturing processes. It directly impacts production efficiency, cost-effectiveness, and overall output quality. In this comprehensive guide, we’ll delve into the intricacies of CNC machine speed, exploring the various factors that influence it and how to optimize performance for different applications.

Understanding CNC Machine Speed

When discussing how fast a CNC machine works, it’s important to consider that “speed” in CNC machining is a multifaceted concept. It encompasses several key parameters:

- Spindle Speed

- Feed Rate

- Cutting Speed

- Rapid Traverse Rate

Each of these components plays a vital role in determining the overall speed and efficiency of a CNC machining operation.

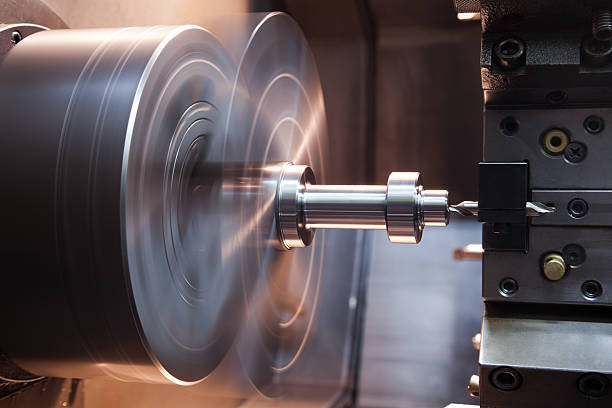

Spindle Speed: The Heart of CNC Performance

Spindle speed, measured in revolutions per minute (RPM), is a fundamental aspect of CNC machine performance. It refers to how fast the cutting tool rotates and is crucial for achieving optimal cutting conditions.

Modern CNC machines can achieve impressive spindle speeds, with some high-performance spindles capable of reaching up to 24,000 RPM or more. These high speeds are particularly beneficial for operations involving small diameter tools or when working with softer materials.

A 24000RPM 3KW ER20 Water-Cooling Spindle, exemplifying high-speed CNC capabilities

However, it’s important to note that the highest spindle speed isn’t always the best choice for every operation. The optimal spindle speed depends on factors such as:

- Material being machined

- Tool diameter

- Desired surface finish

- Tool material and coating

Feed Rate: The Speed of Material Removal

Feed rate is another critical component of CNC machine speed. It refers to the velocity at which the cutting tool is advanced against the workpiece and is typically measured in inches per minute (IPM) or millimeters per minute (mm/min).

The feed rate directly impacts:

- Material removal rate

- Surface finish quality

- Tool life

- Machine stress and vibration

Achieving the right balance in feed rate is crucial. Too slow a feed rate can lead to inefficient production and potential tool damage, while too fast a feed rate can result in poor surface finish or even tool breakage.

Cutting Speed: The Efficiency of Material Removal

Cutting speed, often expressed in surface feet per minute (SFM) or meters per minute (m/min), represents the speed at which the cutting edge of the tool moves relative to the workpiece. It’s a critical factor in determining the efficiency and quality of the machining process.

The optimal cutting speed varies significantly depending on:

- Workpiece material

- Tool material

- Type of machining operation (e.g., roughing vs. finishing)

- Coolant usage

For instance, machining aluminum typically allows for much higher cutting speeds compared to hardened steel.

Rapid Traverse Rate: Maximizing Non-Cutting Efficiency

While not directly related to the cutting process, the rapid traverse rate of a CNC machine significantly impacts overall efficiency. This is the speed at which the machine can move its axes when not cutting, such as when repositioning between cuts.

High-end CNC machines can achieve rapid traverse rates of up to 2,362 inches per minute (60 m/min) or more, significantly reducing non-productive time in complex machining operations.

Factors Influencing CNC Machine Speed

Several factors play a role in determining how fast a CNC machine can effectively operate:

- Machine Capability: The mechanical and electrical design of the machine sets the upper limits for spindle speed, feed rates, and rapid traverse rates.

- Tooling: The quality, material, and design of cutting tools impact the maximum achievable speeds. For example, advanced spindle designs can accommodate higher speeds and precision.

- Workpiece Material: Different materials have varying machinability characteristics, affecting the optimal cutting speeds and feed rates.

- Part Geometry: Complex shapes or features may require slower speeds to maintain accuracy and surface finish quality.

- Fixturing and Workholding: The stability of the workpiece mounting can limit the maximum achievable speeds.

- Programmed Toolpath: Efficient toolpath strategies can significantly impact overall machining speed.

- Operator Skill: An experienced operator can often push a machine to higher speeds while maintaining quality and safety.

A 24000RPM 5.5KW ER25 Water-Cooling Spindle, showcasing advanced CNC spindle technology

Optimizing CNC Machine Speed

To achieve the best balance of speed, quality, and efficiency in CNC machining, consider the following strategies:

- Invest in High-Quality Tooling: Premium cutting tools can withstand higher speeds and maintain their edge longer.

- Utilize Advanced CAM Software: Modern CAM programs can optimize toolpaths for maximum efficiency.

- Implement High-Speed Machining (HSM) Techniques: HSM strategies can significantly increase material removal rates while reducing tool wear.

- Regular Machine Maintenance: Well-maintained machines can operate at higher speeds more reliably.

- Continuous Operator Training: Keeping operators updated on the latest techniques and technologies can lead to improved machine utilization.

- Use of Proper Coolants: Effective cooling and lubrication can allow for higher cutting speeds and feed rates.

The Impact of Spindle Choice on CNC Speed

The choice of spindle can have a significant impact on the overall speed and efficiency of a CNC machine. For instance, air-cooled spindles are often used for lighter duty applications where high speeds are required but not necessarily high power.

An 800W ER11 Air-Cooled Spindle, suitable for high-speed, light-duty applications

On the other hand, water-cooled spindles can typically handle higher speeds and powers, making them ideal for more demanding applications where both high speed and high material removal rates are required.

CNC Speed Across Different Materials

The achievable speed of a CNC machine varies significantly depending on the material being machined. Here’s a general comparison:

| Material | Relative Machining Speed | Factors Influencing Speed |

|---|---|---|

| Aluminum | Fast | Soft, allows for high cutting speeds |

| Mild Steel | Moderate | Harder than aluminum, requires reduced speeds |

| Stainless Steel | Slow | Tough, requires slower speeds and specialized tooling |

| Titanium | Very Slow | Extremely tough, requires specialized techniques |

| Plastics | Very Fast | Soft, can be machined at high speeds but may melt if too fast |

It’s important to note that these are general guidelines, and actual optimal speeds can vary based on specific alloys, heat treatments, and desired surface finishes.

The Role of CNC Controllers in Machine Speed

Modern CNC controllers play a crucial role in determining how fast a CNC machine can work. Advanced controllers offer features such as:

- Look-ahead functionality to anticipate and smooth out complex toolpaths

- Advanced acceleration/deceleration control to maximize speed without sacrificing accuracy

- Real-time tool path optimization

- Adaptive feed control based on actual cutting conditions

These features allow CNC machines to operate at higher speeds while maintaining precision and surface quality.

High-Speed Machining (HSM) and Its Impact on CNC Speed

High-Speed Machining (HSM) is a technique that has revolutionized the concept of speed in CNC machining. HSM involves:

- Higher spindle speeds

- Increased feed rates

- Optimized toolpaths

- Lighter cuts with higher frequency

By employing HSM techniques, manufacturers can achieve:

- Faster overall machining times

- Improved surface finishes

- Reduced tool wear

- The ability to machine thin-walled parts more effectively

However, HSM requires careful planning and often specialized tooling and machine capabilities to be implemented effectively.

The Future of CNC Machine Speed

As technology continues to advance, we can expect to see further improvements in CNC machine speed:

- Advanced Materials: Development of cutting tools that can withstand even higher speeds and temperatures.

- Artificial Intelligence: AI-driven optimization of cutting parameters in real-time.

- Improved Motor and Drive Technologies: Allowing for higher accelerations and faster rapid traverse rates.

- Hybrid Manufacturing: Combining additive and subtractive processes for optimized part production.

These advancements promise to push the boundaries of what’s possible in terms of CNC machining speed and efficiency.

Balancing Speed and Quality in CNC Machining

While the speed of CNC machining is crucial for productivity, it’s equally important to maintain part quality. Achieving the right balance involves:

- Understanding the specific requirements of each job

- Knowing the limitations of your machine and tooling

- Continuous monitoring and adjustment of machining parameters

- Investing in technologies that allow for both high speed and high precision

Remember, the fastest machining time isn’t always the most cost-effective if it leads to increased tool wear, more frequent machine maintenance, or quality issues.

FAQs About CNC Machine Speed

1. What is the average speed of a CNC machine?

The speed of a CNC machine varies widely depending on the operation, material, and machine capabilities. Spindle speeds can range from a few hundred RPM to over 30,000 RPM, while feed rates can vary from a few inches per minute to over 2,000 inches per minute in high-speed machines.

2. How does material hardness affect CNC machining speed?

Material hardness significantly impacts machining speed. Softer materials like aluminum can generally be machined at higher speeds, while harder materials like stainless steel or titanium require slower speeds to prevent tool wear and maintain cut quality.

3. Can increasing CNC machine speed affect part quality?

Yes, increasing speed can affect part quality. While higher speeds can improve productivity, they can also lead to issues like poor surface finish, decreased accuracy, or increased tool wear if not properly optimized for the specific operation and material.

4. How do different CNC operations compare in terms of speed?

Different CNC operations have varying speed capabilities. For example, drilling operations can often be performed at higher speeds than complex 3D milling operations. Turning operations on a CNC lathe might have different speed considerations compared to milling operations.

5. What role does the CNC operator play in determining machine speed?

The CNC operator plays a crucial role in optimizing machine speed. Experienced operators can fine-tune speeds and feeds based on the sound of the cut, visual inspection of chips and surface finish, and their knowledge of the machine’s capabilities and the material being machined.

Conclusion

The speed at which a CNC machine works is a complex interplay of various factors, including spindle speed, feed rate, cutting speed, and rapid traverse rate. While modern CNC machines are capable of impressive speeds, the optimal operating parameters depend on a multitude of factors such as the material being machined, the tooling used, the desired surface finish, and the specific requirements of each job.

Understanding and optimizing these factors is crucial for achieving the best balance of speed, quality, and efficiency in CNC machining operations. As technology continues to advance, we can expect to see further improvements in CNC machine speed and capabilities, driven by developments in areas such as tooling materials, machine design, and control systems.

However, it’s important to remember that speed is just one aspect of CNC machining. The ultimate goal is to produce high-quality parts efficiently and cost-effectively. This often requires finding the right balance between speed and other crucial factors like precision, surface finish, and tool life.

For manufacturers and machine shops, staying informed about the latest developments in CNC technology and continuously optimizing their processes is key to remaining competitive in today’s fast-paced manufacturing environment. By leveraging advanced tools like high-performance spindles, implementing sophisticated CAM strategies, and investing in operator training, businesses can push the boundaries of what’s possible in terms of CNC machining speed and efficiency.

As we look to the future, the ongoing evolution of CNC technology promises to bring even greater speeds and efficiencies to manufacturing processes. From artificial intelligence-driven optimization to advanced materials and hybrid manufacturing techniques, the future of CNC machining is set to be faster, more precise, and more adaptable than ever before.