How Hard Is It to Learn CNC Programming?

CNC programming is a crucial skill in modern manufacturing, enabling the creation of precise and complex parts with computer-controlled machines. For many aspiring machinists and engineers, the question arises: how hard is it to learn CNC programming? The answer is multifaceted, depending on various factors such as prior experience, learning resources, and individual aptitude. In this comprehensive guide, we’ll explore the challenges and opportunities in learning CNC programming, providing insights for beginners and those looking to enhance their skills.

Understanding CNC Programming Basics

Before delving into the difficulty of learning CNC programming, it’s essential to understand what it entails. CNC programming involves creating a set of instructions that guide a computer numerical control (CNC) machine to perform specific operations. These instructions, typically in the form of G-code and M-code, control various aspects of the machine’s operation, including:

- Tool movement and positioning

- Cutting speeds and feed rates

- Tool changes

- Coolant control

- Machine startup and shutdown sequences

The complexity of CNC programming can vary significantly depending on the part being produced and the capabilities of the machine being used.

The Learning Curve of CNC Programming

Learning CNC programming is often compared to learning a new language. Like any language, it has its own syntax, rules, and nuances. The learning curve can be steep initially, but with consistent practice and application, it becomes more intuitive over time.

Key factors that influence the difficulty of learning CNC programming include:

- Prior Experience: Those with a background in machining or programming may find it easier to grasp CNC concepts.

- Mathematical Aptitude: Strong skills in geometry and trigonometry are beneficial for understanding tool paths and spatial relationships.

- Logical Thinking: The ability to break down complex problems into step-by-step processes is crucial in CNC programming.

- Attention to Detail: Precision is paramount in CNC machining, and even small errors in programming can lead to significant issues.

Starting with the Basics: G-code and M-code

The foundation of CNC programming lies in understanding G-code (preparatory code) and M-code (miscellaneous code). These codes form the basic language of CNC machines:

- G-codes: Control the motion of the machine, such as rapid moves, controlled feeds, and canned cycles.

- M-codes: Control miscellaneous functions like tool changes, spindle on/off, and coolant control.

Learning these codes and their functions is the first step in mastering CNC programming. While the list of codes can seem daunting at first, focusing on the most commonly used ones can provide a solid starting point.

The Role of CAM Software in CNC Programming

Computer-Aided Manufacturing (CAM) software has significantly simplified the process of CNC programming, especially for complex parts. CAM software allows programmers to:

- Create or import 3D models of parts

- Define machining operations visually

- Automatically generate G-code based on the defined operations

While CAM software can make programming more accessible, understanding the underlying principles of CNC programming is still crucial for optimizing processes and troubleshooting issues.

Hands-On Experience: The Key to Mastery

Theory and software skills are important, but hands-on experience with CNC machines is invaluable in learning programming. Working with actual machines helps programmers understand:

- How different materials respond to machining operations

- The importance of proper tool selection and setup

- The impact of programming decisions on part quality and machining time

Many successful CNC programmers start by operating machines before moving into programming roles, gaining a holistic understanding of the machining process.

Advanced Concepts in CNC Programming

As programmers progress, they encounter more advanced concepts that can present new challenges:

- Multi-axis machining: Programming for 4-axis or 5-axis machines requires understanding complex tool paths and spatial relationships.

- Parametric programming: Creating flexible, adaptable programs that can handle variations in part dimensions.

- Macro programming: Developing custom subroutines to streamline repetitive tasks and improve efficiency.

- Optimization techniques: Fine-tuning programs to minimize cycle times and improve part quality.

Mastering these advanced concepts often requires dedicated study and practice, but they can significantly enhance a programmer’s capabilities and value in the industry.

The Impact of Machine-Specific Features on Learning

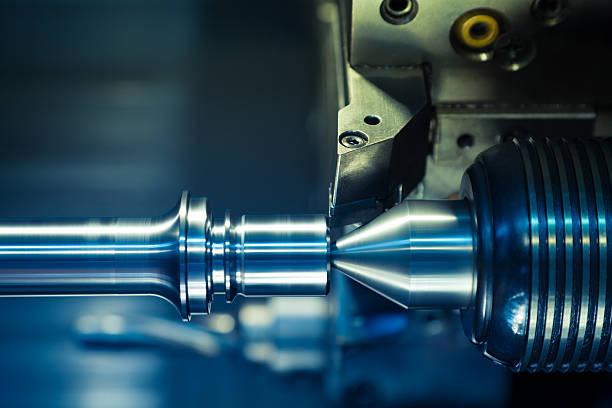

Different CNC machines may have unique features or control systems that affect programming. For example, working with high-performance spindles like the 24000RPM 3KW ER20 Water-Cooling Spindle requires understanding specific programming considerations for high-speed machining.

A 24000RPM 3KW ER20 Water-Cooling Spindle, crucial for advanced CNC operations

Familiarity with various machine types and their capabilities can broaden a programmer’s skill set and adaptability.

Resources for Learning CNC Programming

The availability of learning resources can significantly impact how challenging it is to learn CNC programming. Some valuable resources include:

- Online courses and tutorials: Platforms like Udemy, Coursera, and YouTube offer both free and paid CNC programming courses.

- Technical schools and community colleges: Many institutions offer hands-on CNC programming courses.

- Manufacturer training programs: Machine tool manufacturers often provide training on their specific control systems.

- Textbooks and reference manuals: Comprehensive guides can serve as valuable references throughout a programmer’s career.

- CNC simulators: Software that allows practice without the risk of damaging actual machines.

Utilizing a combination of these resources can provide a well-rounded learning experience.

The Importance of Continuous Learning in CNC Programming

The field of CNC machining is constantly evolving, with new technologies and techniques emerging regularly. Successful CNC programmers embrace continuous learning to stay current with:

- New machine capabilities: Understanding the programming requirements for advanced machines, such as those using high-speed spindles.

- Software updates: Keeping up with the latest CAM software features and updates.

- Industry trends: Staying informed about new machining strategies and best practices.

- Material advancements: Learning how to program for new materials as they become available.

A high-performance 24000RPM 5.5KW ER25 Water-Cooling Spindle, representing advanced CNC technology

This commitment to ongoing education can make the learning process a lifelong journey, but it also ensures that programmers remain valuable and adaptable in their careers.

Overcoming Common Challenges in Learning CNC Programming

While learning CNC programming can be challenging, many common obstacles can be overcome with the right approach:

- Intimidation by complex code: Start with simple programs and gradually increase complexity.

- Lack of hands-on experience: Seek internships or entry-level positions that offer machine time.

- Difficulty visualizing tool paths: Use simulation software to see the results of programming decisions.

- Keeping up with technology: Join professional organizations and attend industry events to stay informed.

- Fear of making mistakes: Practice with simulators before working on actual machines.

The Role of Problem-Solving Skills in CNC Programming

Strong problem-solving skills are crucial in CNC programming. Programmers often need to:

- Troubleshoot issues with code or machining processes

- Optimize programs for efficiency and quality

- Adapt programming techniques to new materials or machine capabilities

- Develop creative solutions for complex machining challenges

Cultivating these skills can make the learning process more manageable and rewarding.

Balancing Theory and Practice in CNC Programming Education

Effective learning of CNC programming typically involves a balance of theoretical knowledge and practical application. This balance can be achieved through:

- Classroom instruction: Learning the principles of CNC programming and machining theory.

- Laboratory work: Hands-on experience with CNC machines and programming software.

- Real-world projects: Applying programming skills to actual manufacturing scenarios.

- Internships or apprenticeships: Gaining experience in professional manufacturing environments.

This balanced approach helps learners connect abstract concepts with practical applications, reinforcing their understanding and skills.

The Impact of Industry Specialization on Learning Difficulty

The difficulty of learning CNC programming can also be influenced by the specific industry or application area:

- Aerospace: Requires high precision and often involves complex, multi-axis machining.

- Medical devices: Demands strict adherence to regulations and often involves working with exotic materials.

- Automotive: May focus on high-volume production and efficiency.

- Prototyping: Requires quick adaptation to new designs and materials.

Specializing in a particular industry may require additional learning but can also lead to expertise in high-demand areas.

Developing a Learning Strategy for CNC Programming

To make the learning process more manageable, consider developing a structured learning strategy:

- Set clear goals: Define what you want to achieve with CNC programming.

- Create a timeline: Establish milestones for your learning journey.

- Combine resources: Utilize a mix of books, online courses, and hands-on practice.

- Join a community: Connect with other learners or professionals for support and advice.

- Practice regularly: Consistent practice is key to mastering CNC programming.

The Future of CNC Programming: Emerging Technologies

As technology advances, new challenges and opportunities arise in CNC programming. Emerging trends include:

- Artificial Intelligence (AI) integration: AI-assisted programming and optimization.

- Virtual and Augmented Reality (VR/AR): Immersive programming and simulation experiences.

- Cloud-based collaboration: Remote programming and machine monitoring capabilities.

- Additive manufacturing integration: Combining CNC and 3D printing technologies.

Staying informed about these trends can help learners prepare for the future of CNC programming.

FAQs About Learning CNC Programming

1. Do I need a college degree to learn CNC programming?

While a college degree can be beneficial, it’s not always necessary. Many successful CNC programmers start with vocational training or on-the-job learning. The most important factors are a strong understanding of machining principles and dedication to continuous learning.

2. How long does it typically take to become proficient in CNC programming?

The time to proficiency can vary, but many learners can achieve basic competence in 6-12 months of dedicated study and practice. Mastery of advanced concepts and specializations may take several years of professional experience.

3. Is it necessary to learn manual machining before CNC programming?

While not strictly necessary, having a background in manual machining can provide valuable insights into cutting processes and tool behavior. This knowledge can enhance your understanding of CNC programming concepts.

4. What are the most challenging aspects of learning CNC programming?

Common challenges include mastering the syntax of G-code and M-code, visualizing complex tool paths, and troubleshooting program errors. Additionally, keeping up with rapidly evolving technology can be demanding.

5. How important is math in CNC programming?

Math, particularly geometry and trigonometry, is crucial in CNC programming. Strong mathematical skills help in understanding tool paths, calculating cutting parameters, and solving complex machining problems.

Conclusion

Learning CNC programming can be challenging, but it’s far from insurmountable. The difficulty largely depends on individual factors such as prior experience, learning resources, and personal aptitude. While the initial learning curve may be steep, with dedication, practice, and the right resources, most individuals can develop proficiency in CNC programming.

The journey to mastering CNC programming is one of continuous learning and adaptation. As technology evolves, so too must the skills of CNC programmers. This ongoing challenge is part of what makes the field exciting and rewarding for many professionals.

For those considering a career in CNC programming, the key is to approach the learning process with patience, persistence, and curiosity. Start with the basics, gain hands-on experience whenever possible, and don’t be afraid to make mistakes – they’re often the best teachers.

Remember that success in CNC programming isn’t just about technical skills. Problem-solving abilities, attention to detail, and a willingness to continuously learn and adapt are equally important. These qualities, combined with technical knowledge, can lead to a fulfilling and successful career in CNC programming.

As the manufacturing industry continues to advance, skilled CNC programmers will remain in high demand. The effort invested in learning this valuable skill set can open doors to exciting opportunities in various industries, from aerospace to medical devices and beyond.

Whether you’re just starting your journey in CNC programming or looking to enhance your existing skills, remember that every expert was once a beginner. With the right mindset and resources, you can overcome the challenges and reap the rewards of this dynamic and crucial field in modern manufacturing.