How long is CNC training?

CNC training is a crucial step for anyone looking to enter the exciting world of computer numerical control machining. Whether you’re considering a career change or wanting to enhance your skills in the manufacturing industry, understanding the timeline for CNC training is essential. In this comprehensive guide, we’ll explore the various aspects of CNC training and provide insights into how long you can expect your educational journey to last.

Understanding the Basics of CNC Machining

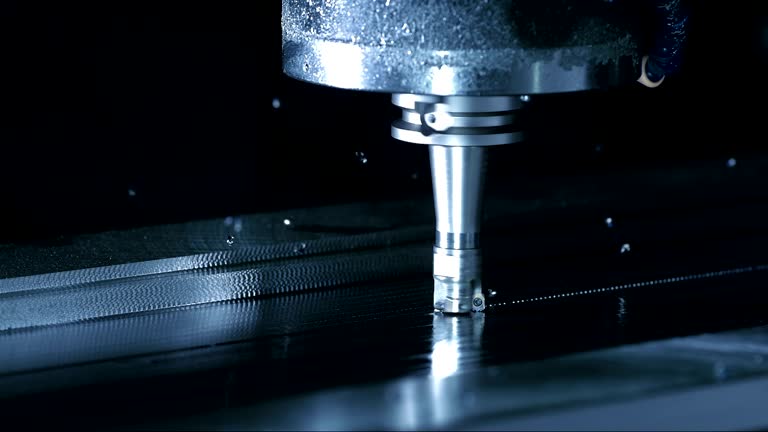

Before diving into the training timeline, it’s important to grasp what CNC machining entails. CNC stands for Computer Numerical Control, and it involves using computers to control machine tools. CNC machines are used to create precision parts for various industries, from aerospace to medical devices.

At the heart of CNC machines are spindle motors, like the 2.2KW ER16 Air-Cooled Spindle, which provide the rotational force necessary for cutting and shaping materials. Understanding these components is a crucial part of CNC training.

The Typical Timeline for CNC Training

The duration of CNC training can vary widely depending on several factors:

- Educational path chosen

- Prior experience in machining or related fields

- Intensity of the training program

- Individual learning pace

Here’s a general overview of the typical timelines for different training approaches:

- Short Courses: 2 weeks to 3 months

- Certificate Programs: 6 months to 1 year

- Associate Degree: 2 years

- Apprenticeship Programs: 3 to 4 years

Short Courses: Quick Introduction to CNC

Short courses offer a rapid introduction to CNC machining. These programs typically focus on:

- Basic CNC concepts

- Introduction to G-code programming

- Safety procedures

- Hands-on practice with simple projects

These courses are ideal for those looking to get a taste of CNC machining or for professionals in related fields who want to expand their skill set quickly.

Certificate Programs: Comprehensive CNC Training

Certificate programs provide a more in-depth education in CNC machining. Over the course of 6 months to a year, students learn:

- Advanced CNC programming techniques

- CAD/CAM software operation

- Quality control and inspection methods

- Machine setup and operation

During these programs, students often work with various types of CNC machines and spindles, such as the 2.2KW ER20 Square Air-Cooled Spindle with Flange, gaining practical knowledge of different machining setups.

Associate Degree: In-Depth CNC Education

An associate degree in CNC machining or manufacturing technology offers a comprehensive education over two years. Students delve into:

- Advanced CNC programming and operation

- Metallurgy and material science

- Precision measurement and quality assurance

- Manufacturing processes and workflow optimization

This level of education prepares students for a wide range of career opportunities in the CNC machining field.

Apprenticeship Programs: Learning on the Job

Apprenticeship programs combine classroom instruction with on-the-job training. Lasting 3 to 4 years, these programs allow aspiring CNC machinists to:

- Gain hands-on experience with various machines

- Work alongside experienced professionals

- Earn a wage while learning

- Develop a strong network in the industry

Factors Affecting CNC Training Duration

Several factors can influence how long it takes to complete CNC training:

- Prior Experience: Those with a background in conventional machining may pick up CNC skills more quickly.

- Learning Ability: Individual aptitude for technical concepts can affect learning speed.

- Training Intensity: Full-time programs will naturally progress faster than part-time options.

- Technology Advancements: Keeping up with the latest CNC technologies may require ongoing training.

The Role of Specialization in CNC Training

Specializing in specific areas of CNC machining can extend the training period but also lead to higher-paying positions. Some specializations include:

- Multi-axis machining

- Micro-machining

- High-speed machining

For example, learning to operate machines with high-speed spindles like the 60000RPM 300W ER8 Water-Cooled Spindle requires additional training due to the precision and speed involved.

Continuous Learning in CNC Machining

It’s important to note that learning in CNC machining doesn’t stop after initial training. The field is constantly evolving, with new technologies and techniques emerging regularly. Continuous learning is essential for CNC machinists to stay competitive in the job market.

The Importance of Hands-on Experience

While classroom learning is crucial, hands-on experience is invaluable in CNC training. Programs that offer extensive practical training often produce more skilled and confident machinists. This is why apprenticeships and programs with internship components are highly valued in the industry.

Balancing Theory and Practice in CNC Training

A well-rounded CNC training program should balance theoretical knowledge with practical skills. Here’s a typical breakdown:

| Theoretical Knowledge | Practical Skills |

|---|---|

| CNC programming | Machine operation |

| CAD/CAM software | Tool selection |

| Material science | Troubleshooting |

| Quality control | Workpiece setup |

Aim for programs that offer a good mix of both aspects for comprehensive learning.

The Role of Certification in CNC Training

While not always mandatory, certifications can enhance a CNC machinist’s credentials and potentially shorten the time needed to secure employment. Popular certifications include:

- NIMS (National Institute for Metalworking Skills) certifications

- MSSC (Manufacturing Skill Standards Council) certifications

- Haas Certification Program

These certifications typically require additional study and testing beyond basic training programs.

Adapting to Different CNC Machines

Part of CNC training involves learning to work with various types of CNC machines. This might include:

- CNC mills

- CNC lathes

- Multi-axis machines

- EDM machines

Each machine type requires specific skills and knowledge, which can add to the overall training time.

The Impact of Technology on CNC Training Duration

Advancements in CNC technology can both shorten and lengthen training times. While modern machines with user-friendly interfaces may be easier to learn initially, the complexity of advanced features can require additional training time to master.

Soft Skills in CNC Training

In addition to technical skills, CNC training often includes developing soft skills such as:

- Problem-solving

- Communication

- Teamwork

- Attention to detail

These skills are crucial for success in the workplace and are typically developed throughout the training period.

The Financial Aspect of CNC Training

When considering how long CNC training takes, it’s important to factor in the financial aspect. Longer programs like associate degrees may have a higher upfront cost but can lead to better-paying positions. Apprenticeships, on the other hand, allow trainees to earn while they learn, offsetting the opportunity cost of full-time education.

Career Prospects After CNC Training

The length of your CNC training can impact your career prospects. Generally, more comprehensive training leads to:

- Higher starting salaries

- Greater job security

- More opportunities for advancement

- Ability to work with more complex machines and projects

FAQs

1. Can I learn CNC machining online?

While some aspects of CNC machining can be learned online, hands-on experience is crucial. Most reputable programs include a significant practical component.

2. How long does it take to become proficient in CNC programming?

Basic proficiency in CNC programming can be achieved in 3-6 months of dedicated study. However, mastering complex programming techniques can take several years of practice and continuous learning.

3. Is prior experience in conventional machining necessary for CNC training?

Prior experience is helpful but not necessary. Many successful CNC machinists start their training with no prior machining experience.

4. How often should I update my CNC skills?

The CNC field evolves rapidly, so it’s recommended to engage in some form of continuing education or skill update every 1-2 years.

5. Can I specialize in CNC machining after completing basic training?

Yes, many machinists choose to specialize after gaining basic proficiency. Specialization can take an additional 6-12 months of focused training.

Conclusion

The journey to becoming a skilled CNC machinist is one of continuous learning and growth. While initial training can range from a few weeks to several years depending on the chosen path, true mastery of the craft comes with experience and ongoing education.

For those passionate about precision manufacturing and technology, the time invested in CNC training is well worth it. The field offers exciting opportunities to work with cutting-edge technology and contribute to the creation of products that shape our world.

Remember, the length of your training is just the beginning. The most successful CNC machinists are those who embrace lifelong learning, staying curious and adaptable in the face of technological advancements. Whether you’re just starting out or looking to enhance your skills, the world of CNC machining offers a rewarding career path for those willing to invest the time and effort into their training.

By understanding the various training options and timelines available, you can make an informed decision about your career path in CNC machining. Whether you choose a quick certificate program or a comprehensive apprenticeship, the skills you gain will open doors to a thriving industry that’s always in need of skilled professionals.