How Many Axes in a CNC Lathe Machine?

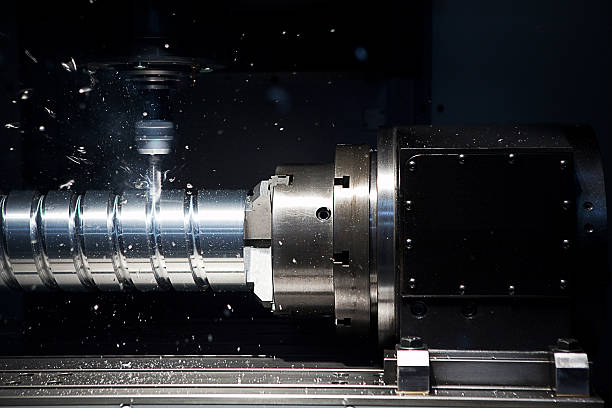

CNC lathe machines are a cornerstone of modern manufacturing, offering precision and efficiency in creating cylindrical parts. One of the key factors that determine a CNC lathe’s capabilities is the number of axes it possesses. In this comprehensive guide, we’ll explore the various axis configurations in CNC lathe machines, their functions, and how they impact machining processes.

Understanding CNC Lathe Machine Axes

CNC lathe machines operate on a coordinate system that defines the movement of the cutting tool relative to the workpiece. The number of axes a machine has directly correlates to its complexity and versatility. Let’s delve into the basics of these axes and their significance in machining operations.

The Fundamental Axes: X and Z

At its core, a basic CNC lathe machine operates on two primary axes:

- X-axis: This axis represents the radial movement of the cutting tool, controlling the depth of cut into the workpiece.

- Z-axis: This axis represents the longitudinal movement of the cutting tool along the length of the workpiece.

These two axes allow for basic turning operations, creating cylindrical shapes and contours. However, modern CNC lathes often incorporate additional axes to enhance their capabilities.

Beyond the Basics: Additional Axes in CNC Lathes

As machining requirements become more complex, manufacturers have developed CNC lathes with additional axes to meet these demands. Let’s explore some of these advanced configurations.

The Y-axis: Adding Milling Capabilities

Many modern CNC lathes incorporate a Y-axis, which allows for off-center machining operations. This addition effectively transforms the lathe into a multi-tasking machine capable of both turning and milling operations.

<svg xmlns="http://www.w3.org/2000/svg" viewBox="0 0 300 200">

<rect x="50" y="80" width="200" height="40" fill="#ccc" stroke="#000"/>

<line x1="150" y1="0" x2="150" y2="200" stroke="#f00" stroke-width="2"/>

<line x1="0" y1="100" x2="300" y2="100" stroke="#00f" stroke-width="2"/>

<line x1="150" y1="60" x2="150" y2="140" stroke="#0f0" stroke-width="2"/>

<text x="280" y="110" fill="#00f">X</text>

<text x="160" y="20" fill="#f00">Y</text>

<text x="160" y="95" fill="#0f0">Z</text>

<text x="100" y="180" font-size="14">Y-axis CNC Lathe</text>

</svg>The Y-axis allows for:

- Off-center drilling and tapping

- Contour milling

- Polygon turning

For those interested in advanced machining capabilities, the 2.2KW ER20 Air-Cooled Spindle offers the power and precision needed for complex Y-axis operations.

C-axis: Rotational Control

The C-axis refers to the rotational movement of the spindle. This axis allows for precise angular positioning of the workpiece, enabling:

- Indexed milling operations

- Helical milling

- Precise part orientation for complex machining

4-Axis and 5-Axis CNC Lathes

As we move into more advanced territory, 4-axis and 5-axis CNC lathes offer even greater flexibility and capability.

4-Axis CNC Lathes

A 4-axis CNC lathe typically includes:

- X-axis

- Z-axis

- Y-axis or C-axis

This configuration allows for a wide range of complex machining operations, including off-center milling and precise angular positioning.

5-Axis CNC Lathes

5-axis CNC lathes represent the pinnacle of lathe machine technology, incorporating:

- X-axis

- Z-axis

- Y-axis

- C-axis

- B-axis (tool head tilt)

These machines can perform extremely complex machining operations, creating intricate parts with minimal setup time.

For those looking to upgrade their machining capabilities, the 4.5KW ER32 Air-Cooled Spindle provides the power and precision needed for advanced 5-axis operations.

The Impact of Multiple Axes on Machining Processes

The number of axes in a CNC lathe machine significantly impacts its capabilities and the types of parts it can produce. Let’s explore how additional axes enhance machining processes:

- Increased Complexity: More axes allow for the creation of more complex geometries in a single setup.

- Improved Efficiency: Multi-axis machines can often complete parts in a single setup, reducing handling time and improving accuracy.

- Enhanced Surface Finish: The ability to approach the workpiece from multiple angles can result in superior surface finishes.

- Reduced Setup Time: Fewer setups mean less time spent on workholding and part transfers.

Choosing the Right CNC Lathe for Your Needs

Selecting the appropriate CNC lathe depends on various factors, including:

- Part complexity

- Production volume

- Budget

- Available floor space

- Operator skill level

For many applications, a 3-axis CNC lathe (X, Z, and C axes) provides an excellent balance of capability and cost-effectiveness. The 3.5KW ER20 Air-Cooled Spindles offer robust performance for such machines.

Advanced Features in Multi-Axis CNC Lathes

Modern multi-axis CNC lathes come equipped with a range of advanced features that further enhance their capabilities:

- Live Tooling: This feature allows rotating cutting tools to be used in a lathe, enabling milling operations.

- Sub-Spindle: A secondary spindle allows for back-end operations, reducing the need for part flipping.

- Tool Turret: Rapid tool changes increase productivity and reduce downtime.

- Tailstock: Provides support for long workpieces, improving accuracy and surface finish.

The Future of CNC Lathe Axes

As manufacturing technology continues to evolve, we can expect to see further advancements in CNC lathe axis configurations. Some potential developments include:

- Integration of additive manufacturing capabilities

- Enhanced sensor technology for real-time process optimization

- AI-driven axis control for improved precision and efficiency

Maintenance Considerations for Multi-Axis CNC Lathes

With increased complexity comes the need for more comprehensive maintenance. Here are some key considerations:

- Regular Calibration: Ensure all axes are properly aligned and calibrated.

- Lubrication: Proper lubrication of all moving parts is crucial for longevity.

- Software Updates: Keep the machine’s control software up-to-date for optimal performance.

- Operator Training: Invest in thorough training to maximize the machine’s capabilities.

Economic Impact of Multi-Axis CNC Lathes

The adoption of multi-axis CNC lathes can have significant economic benefits:

- Reduced Labor Costs: Fewer setups and faster cycle times mean less operator intervention.

- Improved Part Quality: Higher precision leads to fewer rejects and reworks.

- Increased Competitiveness: The ability to produce complex parts quickly can open new market opportunities.

Case Studies: Multi-Axis CNC Lathes in Action

Let’s examine some real-world applications of multi-axis CNC lathes:

- Aerospace Industry: 5-axis CNC lathes are used to produce complex turbine blades with high precision.

- Medical Device Manufacturing: Multi-axis lathes create intricate implants and surgical instruments.

- Automotive Sector: 4-axis lathes efficiently produce engine components with tight tolerances.

Environmental Considerations

Modern multi-axis CNC lathes also contribute to more sustainable manufacturing practices:

- Reduced Material Waste: More precise machining leads to less material waste.

- Energy Efficiency: Advanced spindle motors, like the 5.5KW ER32 4-Pole Air-Cooled Spindle, offer improved energy efficiency.

- Coolant Recycling: Many modern machines incorporate coolant recycling systems to reduce environmental impact.

FAQs

1. What is the most common axis configuration for CNC lathes?

The most common configuration is a 2-axis setup with X and Z axes, which is suitable for basic turning operations. However, 3-axis lathes with an additional C-axis for rotational control are becoming increasingly popular.

2. How does a Y-axis benefit CNC lathe operations?

A Y-axis allows for off-center machining, enabling milling operations, off-center drilling, and more complex part geometries to be produced in a single setup.

3. Are 5-axis CNC lathes worth the investment for small machine shops?

While 5-axis CNC lathes offer incredible versatility, they may not be cost-effective for all small shops. The decision depends on the complexity of parts produced, production volume, and potential for new business opportunities.

4. Can a multi-axis CNC lathe replace a machining center?

In many cases, yes. Multi-axis CNC lathes, especially those with live tooling, can perform many of the functions of a machining center, often with the added benefit of completing parts in a single setup.

5. How does the number of axes affect programming complexity?

Generally, more axes mean more complex programming. However, modern CAM software has made programming multi-axis machines much more accessible, often automating much of the process.

6. What industries benefit most from multi-axis CNC lathes?

Industries that require complex, high-precision parts benefit most from multi-axis CNC lathes. These include aerospace, medical device manufacturing, automotive, and high-end consumer products.

Conclusion

The number of axes in a CNC lathe machine is a crucial factor in determining its capabilities and the complexity of parts it can produce. From basic 2-axis machines to advanced 5-axis systems, each configuration offers unique advantages and applications. As technology continues to advance, we can expect to see even more innovative axis configurations that push the boundaries of what’s possible in machining.

When considering a CNC lathe for your operations, carefully evaluate your current and future needs. While more axes offer greater flexibility, they also come with increased complexity and cost. By understanding the capabilities and limitations of different axis configurations, you can make an informed decision that balances capability, efficiency, and cost-effectiveness for your specific manufacturing requirements.

Remember, the right machine is not always the most complex one, but the one that best fits your production needs and helps you stay competitive in an ever-evolving manufacturing landscape.