How Much Are CNC Machines?

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, offering precision, efficiency, and versatility in various applications. However, one of the most common questions potential buyers ask is, “How much are CNC machines?” The answer to this question is not straightforward, as the cost of CNC machines can vary significantly based on several factors. In this comprehensive guide, we’ll explore the price range of CNC machines, factors affecting their cost, and how to choose the right machine for your budget and needs.

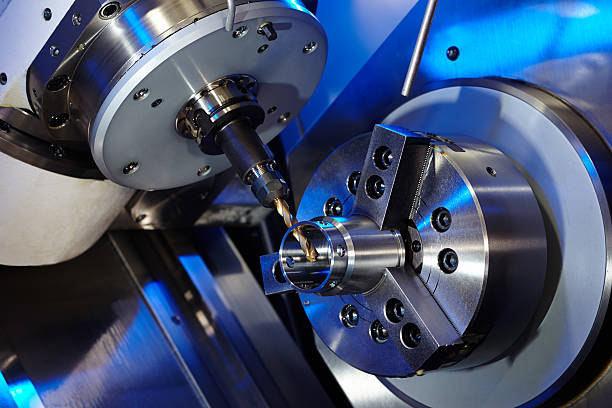

Understanding CNC Machines and Their Applications

Before delving into the costs, it’s essential to understand what CNC machines are and their applications. CNC machines are automated manufacturing tools that use computer programming to control the movement of cutting tools and other components. These machines are used in a wide range of industries, including aerospace, automotive, and electronics manufacturing.

Some common types of CNC machines include:

- CNC routers

- CNC milling machines

- CNC lathes

- CNC plasma cutters

- CNC laser cutters

Each type of machine serves different purposes and comes with its own price range. For instance, a CNC router might be used for woodworking and sign-making, while a CNC milling machine is more suited for metal fabrication.

The Price Range of CNC Machines

The cost of CNC machines can range from a few thousand dollars to several hundred thousand dollars, depending on various factors. Here’s a general breakdown of the price ranges:

- Entry-level CNC machines: $5,000 – $25,000

- Mid-range CNC machines: $25,000 – $75,000

- High-end CNC machines: $75,000 – $500,000+

It’s important to note that these are just rough estimates, and prices can vary significantly based on the specific machine, brand, and features.

Factors Affecting CNC Machine Costs

Several factors contribute to the overall cost of a CNC machine. Understanding these factors can help you make an informed decision when budgeting for your CNC machine purchase.

1. Size and Working Area

The size of the machine and its working area directly impact the cost. Larger machines with bigger working areas generally cost more due to increased material costs and complexity.

2. Precision and Accuracy

Higher precision and accuracy often come with a higher price tag. Machines designed for intricate work in industries like aerospace or medical device manufacturing typically cost more than those used for less demanding applications.

3. Speed and Power

The cutting speed and power of the machine affect its productivity and, consequently, its price. Faster, more powerful machines are generally more expensive but can offer increased efficiency in high-volume production environments.

4. Materials and Build Quality

The quality of materials used in constructing the machine, as well as its overall build quality, significantly impact the price. Machines built with high-grade materials and superior craftsmanship tend to be more expensive but often offer better longevity and performance.

5. Spindle Type and Power

The spindle is a crucial component of any CNC machine. Higher-power spindles capable of handling more demanding tasks typically increase the overall cost of the machine. For example, a 5.5KW water-cooled spindle will generally be more expensive than a lower-power air-cooled spindle.

6. Automatic Tool Changer (ATC)

Machines equipped with an automatic tool changer can significantly increase productivity but also come with a higher price tag. The complexity and capacity of the ATC system can further affect the cost.

7. Control System and Software

The sophistication of the control system and accompanying software can greatly influence the machine’s price. More advanced control systems with features like 3D simulation and multi-axis coordination tend to be more expensive.

8. Brand and Origin

Well-known brands with a reputation for quality and reliability often command higher prices. Similarly, machines manufactured in countries with higher labor costs may be more expensive than those produced in countries with lower manufacturing costs.

Cost Comparison of Different CNC Machine Types

To give you a better idea of how costs can vary across different types of CNC machines, let’s look at a general price comparison:

| Machine Type | Entry-Level Cost | Mid-Range Cost | High-End Cost |

|---|---|---|---|

| CNC Router | $5,000 – $15,000 | $15,000 – $50,000 | $50,000 – $150,000+ |

| CNC Mill | $10,000 – $30,000 | $30,000 – $100,000 | $100,000 – $500,000+ |

| CNC Lathe | $15,000 – $40,000 | $40,000 – $150,000 | $150,000 – $750,000+ |

| CNC Plasma Cutter | $5,000 – $20,000 | $20,000 – $75,000 | $75,000 – $200,000+ |

| CNC Laser Cutter | $10,000 – $30,000 | $30,000 – $100,000 | $100,000 – $500,000+ |

Remember, these are approximate ranges, and actual prices can vary based on the factors mentioned earlier.

Budget Considerations for CNC Machine Purchases

When budgeting for a CNC machine, it’s crucial to look beyond the initial purchase price. Here are some additional costs to consider:

- Installation and Setup: This can include costs for transportation, electrical work, and initial calibration.

- Training: Proper training for operators is essential and may incur additional costs.

- Tooling and Accessories: The cost of cutting tools, workholding devices, and other accessories can add up quickly.

- Maintenance and Repairs: Regular maintenance and potential repairs should be factored into your budget.

- Software and Upgrades: CAD/CAM software licenses and future upgrades can be significant expenses.

- Energy Consumption: More powerful machines typically consume more energy, which can impact long-term operational costs.

Choosing the Right CNC Machine for Your Budget

Selecting the right CNC machine within your budget requires careful consideration of your specific needs and production requirements. Here are some tips to help you make an informed decision:

- Assess Your Production Needs: Determine the type of work you’ll be doing, the materials you’ll be working with, and your production volume.

- Consider Future Growth: While it’s important to stay within budget, also consider potential future needs to avoid outgrowing your machine too quickly.

- Compare Features and Specifications: Look beyond the price tag and compare the features and specifications of different machines within your budget range.

- Evaluate Total Cost of Ownership: Consider long-term costs such as maintenance, energy consumption, and potential upgrades.

- Read Reviews and Get Recommendations: Research user reviews and seek recommendations from industry peers to get insights into the performance and reliability of different machines.

- Consider Used or Refurbished Options: If budget is a major constraint, consider looking into used or refurbished CNC machines, which can offer significant savings.

The Impact of CNC Machine Cost on Business Operations

The cost of a CNC machine can have a significant impact on your business operations. While a more expensive machine might seem like a bigger investment upfront, it could potentially offer better efficiency, accuracy, and productivity in the long run. On the other hand, a budget-friendly option might be sufficient for smaller operations or those just starting out.

Consider the following when evaluating the impact of CNC machine cost on your business:

- Return on Investment (ROI): Calculate the potential ROI based on increased productivity and quality improvements.

- Production Capacity: Ensure the machine’s capabilities align with your current and projected production needs.

- Competitive Advantage: Consider how the machine’s capabilities could give you an edge over competitors.

- Workforce Skills: Factor in the skill level required to operate and maintain the machine.

Financing Options for CNC Machines

Given the substantial investment required for CNC machines, many businesses explore financing options. Here are some common financing methods:

- Bank Loans: Traditional bank loans can provide the necessary capital for purchasing CNC machines.

- Equipment Leasing: Leasing allows you to use the machine without a large upfront investment.

- Manufacturer Financing: Some CNC machine manufacturers offer their own financing programs.

- Government Grants and Subsidies: Depending on your location and industry, you might be eligible for government assistance.

- Crowdfunding: For smaller businesses or unique projects, crowdfunding could be an unconventional but potentially effective option.

Future Trends Affecting CNC Machine Costs

As technology continues to evolve, several trends are likely to impact CNC machine costs in the future:

- Increased Automation: Advanced automation features may increase initial costs but could lead to long-term savings through increased efficiency.

- Integration of AI and Machine Learning: These technologies could enhance machine capabilities but may also increase costs.

- Additive Manufacturing Integration: Some CNC machines are incorporating 3D printing capabilities, which could affect pricing.

- Energy Efficiency: As energy costs rise, more energy-efficient machines may command higher prices but offer long-term savings.

Case Studies: Real-World CNC Machine Costs

To provide a more concrete understanding of CNC machine costs, let’s look at a few case studies:

- Small Woodworking Shop: A small furniture maker invested $15,000 in a CNC router with a 1.5KW spindle. This entry-level machine allowed them to increase production and take on more complex projects.

- Medium-Sized Metal Fabrication Company: A growing metal fabrication business purchased a CNC milling machine for $85,000. The machine’s higher precision and automatic tool changer significantly improved their production capacity.

- Large Aerospace Manufacturer: A major aerospace parts manufacturer invested $450,000 in a high-end 5-axis CNC machining center. The machine’s advanced capabilities and extreme precision were essential for producing complex aerospace components.

The Role of Spindles in CNC Machine Cost and Performance

The spindle is a crucial component of any CNC machine, playing a significant role in both the cost and performance of the system. High-quality spindles, such as those offered by Spindle Motor Shop, can greatly enhance the capabilities of your CNC machine.

For instance, the 4.5KW ER20 water-cooled spindle offers high power and precision for demanding applications. While it may increase the initial cost of the machine, it can lead to improved performance and longevity, potentially offering better value in the long run.

Making the Final Decision

Choosing the right CNC machine at the right price is a balance between your current needs, future growth potential, and available budget. Remember, the cheapest option isn’t always the most cost-effective in the long run, nor is the most expensive machine necessarily the best fit for your needs.

Take the time to thoroughly research your options, consult with experts, and perhaps even visit manufacturing facilities to see different machines in action. By making an informed decision, you can ensure that your investment in a CNC machine will pay off in improved productivity, quality, and competitiveness for your business.

Conclusion

The cost of CNC machines can vary widely, from a few thousand dollars for entry-level models to hundreds of thousands for high-end, industrial-grade machines. The price depends on factors such as size, precision, speed, materials, and additional features like automatic tool changers.

When budgeting for a CNC machine, it’s crucial to consider not just the initial purchase price, but also ongoing costs such as maintenance, energy consumption, and potential upgrades. By carefully assessing your needs, researching your options, and considering long-term value, you can find a CNC machine that fits your budget while meeting your production requirements.

Remember, investing in a CNC machine is not just about the cost—it’s about enhancing your production capabilities, improving efficiency, and staying competitive in an increasingly automated manufacturing landscape. With the right machine, you can take your manufacturing processes to the next level, opening up new possibilities for your business.

FAQs

What is the cheapest CNC machine available?

The cheapest CNC machines are typically small desktop routers or engravers, which can be found for as little as $500-$1,000. However, these machines are usually limited in size, power, and capabilities, suitable mainly for hobbyists or very small-scale operations.

How much does a professional-grade CNC machine cost?

Professional-grade CNC machines typically start around $25,000 and can go up to several hundred thousand dollars. The exact cost depends on the type of machine, its capabilities, and the specific features included.

Is it worth buying a used CNC machine to save money?

Buying a used CNC machine can be a good way to save money, especially for smaller businesses or those just starting out. However, it’s important to thoroughly inspect the machine, check its maintenance history, and consider potential repair or upgrade costs before making a purchase.

How do CNC machine costs compare to traditional manual machines?

CNC machines are generally more expensive than their manual counterparts due to their advanced technology and automation capabilities. However, they often offer greater precision, consistency, and productivity, which can justify the higher initial investment for many businesses.

What additional costs should I consider when budgeting for a CNC machine?

When budgeting for a CNC machine, consider additional costs such as installation, training, tooling, software, maintenance, and potential facility modifications. These can add significantly to the total cost of ownership.

How long does it typically take to see a return on investment for a CNC machine?

The time to see a return on investment (ROI) for a CNC machine can vary widely depending on factors such as machine utilization, production volume, and the value of the parts produced. Some businesses may see ROI within a year, while for others it might take several years. It’s important to do a thorough cost-benefit analysis based on your specific situation.