How Much Can You Make with a CNC Machine?

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, offering precision, efficiency, and versatility in various applications. But beyond their technical capabilities, many entrepreneurs and hobbyists are curious about the earning potential of these powerful tools. In this comprehensive guide, we’ll explore the question: “How much can you make with a CNC machine?” We’ll delve into various business models, profit potential, and factors that influence your earning capacity in the CNC industry.

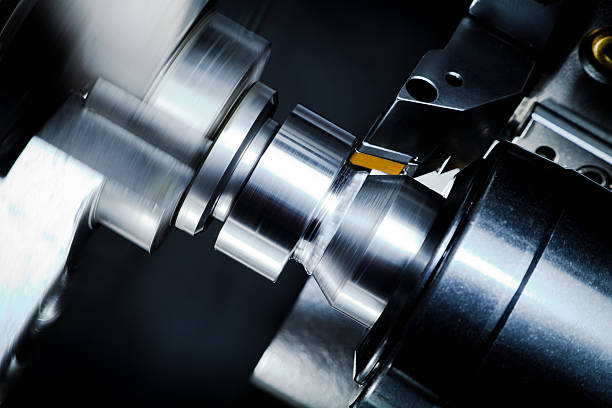

Understanding the CNC Machine Market

Before we dive into the earnings potential, it’s crucial to understand the CNC machine market. CNC machines come in various types, sizes, and capabilities, each suited for different applications. From small desktop CNC routers to large industrial milling centers, the range of machines available is vast.

One popular option for those starting in the CNC business is a 2.2KW ER20 air-cooled spindle, which offers a good balance of power and precision for many applications.

A 2.2KW ER20 air-cooled spindle, suitable for various CNC applications

Factors Affecting Earning Potential with CNC Machines

Several factors influence how much you can make with a CNC machine:

- Machine Capabilities: The type and capabilities of your CNC machine directly impact what you can produce and, consequently, your earning potential.

- Skill Level: Your proficiency in operating the machine, designing products, and problem-solving affects productivity and quality.

- Market Demand: The demand for CNC-produced items in your area or target market plays a significant role in your earning potential.

- Business Model: Whether you’re offering services, creating products, or both will impact your earnings.

- Niche Selection: Specializing in a particular niche can lead to higher profits due to less competition and higher perceived value.

- Marketing and Sales Skills: Your ability to market your services or products and close sales is crucial for success.

- Operational Efficiency: Managing costs, optimizing production processes, and maintaining your machine properly all contribute to profitability.

Business Models for CNC Machine Owners

There are several ways to make money with a CNC machine. Let’s explore some popular business models:

1. Custom Fabrication Services

Offering custom fabrication services is a common way to make money with a CNC machine. This model involves creating custom parts or products for clients based on their specifications.

Potential Earnings: $50 – $150 per hour, depending on complexity and material costs.

2. Product Manufacturing

Creating and selling your own line of products can be highly profitable. This could include anything from home decor items to specialized tools.

Potential Earnings: Varies widely, but successful product lines can generate $5,000 – $20,000+ per month.

3. Prototyping Services

Many inventors and product designers need prototypes. Offering rapid prototyping services can be lucrative, especially if you have a high-speed spindle like the 60000RPM 1.2KW ER11 water-cooled model.

A high-speed 60000RPM 1.2KW ER11 water-cooled spindle, ideal for rapid prototyping

Potential Earnings: $75 – $200 per hour, depending on complexity and turnaround time.

4. CNC Education and Training

If you’re skilled with CNC machines, you could offer training courses or workshops to others looking to enter the field.

Potential Earnings: $500 – $2,000 per student for a comprehensive course.

5. Niche Market Products

Specializing in a particular niche, such as custom guitar parts or model railroad components, can lead to higher profits due to less competition.

Potential Earnings: Highly variable, but successful niche businesses can earn $10,000 – $50,000+ per month.

Real-World Examples of CNC Machine Earnings

To give you a better idea of the earning potential, let’s look at some real-world examples:

- Custom Sign Making Business: A small business owner using a CNC router to create custom wooden signs reports earning $5,000 – $8,000 per month after expenses.

- Prototype Service Provider: An engineer offering CNC prototyping services to local businesses earns an average of $12,000 per month, working primarily with a 3KW ER20 water-cooled spindle.

- Custom Furniture Maker: A woodworker using CNC machines to create high-end custom furniture pieces reports annual earnings of over $150,000.

- Industrial Parts Manufacturer: A small machine shop specializing in precision CNC-milled parts for the aerospace industry generates over $500,000 in annual revenue.

Maximizing Your Earnings with CNC Machines

To maximize your earnings with a CNC machine, consider the following strategies:

- Invest in Quality Equipment: While it may be tempting to start with a budget machine, investing in quality equipment like a 4.5KW ER20 water-cooled spindle can increase your capabilities and efficiency.

A powerful 4.5KW ER20 water-cooled spindle for high-performance CNC applications

- Develop Your Skills: Continuously improve your CNC programming, design, and machining skills to take on more complex and lucrative projects.

- Focus on High-Value Markets: Target industries that require precision parts and are willing to pay premium prices, such as aerospace or medical device manufacturing.

- Offer Value-Added Services: Provide additional services like design consultation, finishing, or assembly to increase the value of your offerings.

- Optimize Your Workflow: Implement efficient processes to reduce production time and increase output without sacrificing quality.

- Build a Strong Online Presence: Use social media, a professional website, and online marketplaces to showcase your work and attract clients.

- Network and Partner: Build relationships with complementary businesses to expand your reach and tap into new markets.

Challenges and Considerations

While the earning potential with CNC machines can be significant, it’s important to be aware of the challenges:

- Initial Investment: Quality CNC machines and tools require a substantial upfront investment.

- Learning Curve: Mastering CNC operation and programming takes time and dedication.

- Competition: The CNC market can be competitive, especially in saturated areas.

- Maintenance Costs: Regular maintenance and occasional repairs are necessary expenses.

- Material Costs: Fluctuations in material prices can affect your profit margins.

The Future of CNC Machine Earnings

The future looks bright for those skilled in CNC machining. As technology advances, new opportunities are emerging:

- Industry 4.0 Integration: CNC machines are becoming more connected and data-driven, opening up new service possibilities.

- Hybrid Manufacturing: Combining CNC machining with 3D printing is creating new market opportunities.

- Sustainable Manufacturing: There’s growing demand for CNC services that prioritize sustainability and eco-friendly practices.

- Customization Trends: The increasing demand for personalized products bodes well for CNC machine owners.

Getting Started with CNC Machine Earnings

If you’re new to the world of CNC machining and looking to start earning, here are some steps to get started:

- Educate Yourself: Take courses, watch tutorials, and practice with CAD/CAM software.

- Start Small: Begin with a manageable machine like a desktop CNC router to learn the basics.

- Identify Your Niche: Determine what products or services you want to offer based on your skills and local market demands.

- Create a Business Plan: Outline your startup costs, pricing strategy, and marketing approach.

- Build a Portfolio: Create sample products to showcase your capabilities to potential clients.

- Network: Join CNC forums, attend trade shows, and connect with potential clients and fellow machinists.

Scaling Your CNC Business

As your skills improve and your business grows, consider these strategies for scaling:

- Expand Your Equipment: Invest in additional or more advanced machines to take on larger projects.

- Hire and Train: Bring on skilled operators to increase production capacity.

- Diversify Services: Add complementary services like design or finishing to become a one-stop shop.

- Explore E-commerce: Sell your products online to reach a broader customer base.

- Seek Commercial Contracts: Partner with businesses for recurring orders to stabilize income.

FAQs

What is the average startup cost for a CNC machine business?

The startup cost can range from $5,000 for a small desktop setup to $100,000+ for a professional-grade CNC machine and associated equipment. This includes the machine, tools, software, and initial materials.

How long does it take to become proficient with a CNC machine?

With dedicated practice, you can become proficient in basic operations within 3-6 months. However, mastering complex techniques and becoming highly efficient can take several years of experience.

Can I make money with a CNC machine as a side hustle?

Yes, many people start CNC machining as a side hustle. You can begin by taking on small projects or creating products in your spare time, gradually building your business as demand grows.

What are some of the most profitable products to make with a CNC machine?

Profitable products often include custom signage, personalized gifts, specialized industrial parts, high-end furniture components, and prototypes for inventors. The key is to find a niche that aligns with your skills and has strong market demand.

How important is the choice of CNC spindle in determining earning potential?

The choice of spindle is crucial as it affects the types of materials you can work with, the speed and precision of your work, and the overall quality of your output. A high-quality spindle like the 5.5KW ER25 water-cooling spindle can significantly increase your capabilities and, consequently, your earning potential.

A high-performance 5.5KW ER25 water-cooling spindle for advanced CNC applications

Is it better to offer services or create products when starting with CNC machining?

Both approaches can be profitable. Offering services can provide a steady income and help you build skills across various projects. Creating products allows for scalability and potentially higher profits but may require more upfront investment in design and marketing. Many successful CNC businesses do a combination of both.

Conclusion

The earning potential with CNC machines is significant and varied. From small side hustles earning a few thousand dollars a month to full-scale operations generating six-figure annual revenues, the possibilities are vast. Your success will depend on factors such as your skills, chosen niche, business acumen, and the quality of your equipment.

Remember that while the potential for high earnings exists, it requires dedication, continuous learning, and smart business strategies. Start by identifying your strengths and the needs of your target market. Invest in quality equipment, like reliable spindles from reputable suppliers, to ensure you can deliver high-quality work consistently.

Whether you’re looking to supplement your income or build a full-fledged CNC machining business, the key is to start small, learn continuously, and grow strategically. With persistence and the right approach, a CNC machine can indeed become a valuable tool for generating substantial income.

As the manufacturing landscape continues to evolve, those with CNC skills are well-positioned to capitalize on new opportunities. By staying informed about industry trends and continuously improving your capabilities, you can ensure that your CNC machine remains a profitable investment for years to come.