In the world of modern manufacturing, CNC programmers play a crucial role in transforming raw materials into high-precision components that power industries worldwide. CNC (Computer Numerical Control) programming is not only a highly technical field but also one that offers significant rewards in terms of job satisfaction, career growth, and, of course, salary. But how much does a CNC programmer make? This guide will explore the various factors that influence CNC programmer salaries, including skill level, experience, location, and industry demands.

Understanding the Role of a CNC Programmer

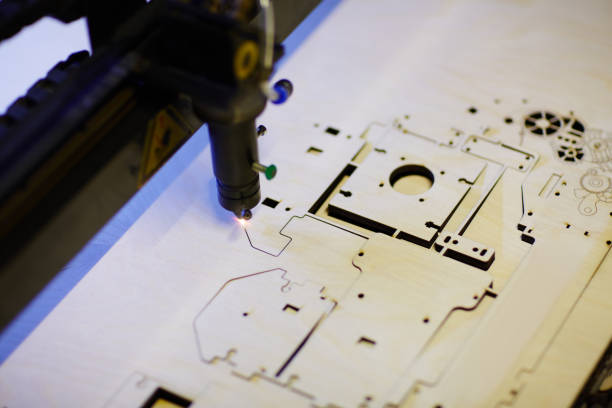

Before diving into salary details, it’s essential to understand what CNC programmers do. A CNC programmer is responsible for creating the instructions—using G-code or CAM software—that CNC machines follow to manufacture parts from materials like metals, plastics, and composites. They are instrumental in setting up, testing, and troubleshooting these programs to ensure precision in manufacturing.

Key Responsibilities of a CNC Programmer

- Creating CNC Programs: CNC programmers write G-code or use CAM software to translate a CAD model into instructions the CNC machine can understand.

- Tool Selection and Setup: Choosing the right cutting tools for specific jobs, such as spindle motors like the 6KW Air-Cooled Spindle, is vital for efficient production.

- Troubleshooting Programs: Detecting errors in the programming and making necessary adjustments to optimize the machining process.

- Ensuring Quality: Monitoring the finished parts to ensure they meet specifications and tolerances.

The role of a CNC programmer is challenging and requires a deep understanding of machining processes, CNC machine operations, tooling, and software like Mastercam or Fusion 360. Programmers must know the material properties and how they interact with different cutting tools to produce high-quality results consistently.

Factors That Influence CNC Programmer Salaries

The salary of a CNC programmer is influenced by multiple factors, including experience, level of expertise, industry, and geographical location. Let’s break down how each of these elements affects earning potential.

Experience Level

Experience is perhaps the most critical factor affecting a CNC programmer’s salary. As programmers gain experience, they become more adept at handling complex machining projects, selecting suitable tools like the 2.2KW ER20 Air-Cooled Spindle, and troubleshooting errors effectively.

- Entry-Level Programmers: Fresh graduates or those with limited experience generally earn between $35,000 – $45,000 annually. These programmers often start by assisting more experienced team members, gradually taking on more responsibilities as they learn.

- Mid-Level Programmers: With 3-5 years of experience, salaries typically range from $50,000 – $65,000. Mid-level programmers handle more complex tasks and may begin specializing in either CNC mills or lathes, depending on their skills.

- Senior Programmers: Highly experienced CNC programmers, with 10 or more years in the field, can expect to earn anywhere from $70,000 to over $90,000 annually, depending on their expertise and industry.

Industry Type

The type of industry where a CNC programmer works also plays a significant role in determining salary. Some industries pay higher wages due to the complexity and precision required for the components produced.

- Aerospace and Defense: CNC programmers in aerospace often work with complex geometries and tight tolerances, requiring more expertise. Salaries here are generally on the higher end of the spectrum.

- Automotive Industry: CNC programmers who work in the automotive industry may have to deal with large production runs, which focus on efficiency and precision. Salaries are competitive, but not as high as aerospace.

- Medical Devices: The medical device industry demands precision and accuracy, and CNC programmers in this field can command premium salaries.

Geographic Location

Geographic location greatly influences how much CNC programmers make. Programmers working in regions with a high cost of living, such as California, often earn more than those working in rural areas.

- California and New York: Average annual salaries range between $75,000 and $95,000, reflecting the higher cost of living and the demand for advanced manufacturing.

- Midwestern States: Areas like Ohio and Michigan have a strong manufacturing base. Salaries range from $50,000 – $70,000 but often come with more job security due to the high concentration of manufacturing facilities.

- Southern States: States like Texas and Alabama offer salaries in the range of $45,000 – $65,000, often balanced with a lower cost of living.

How Certification and Skills Impact Salary

Certifications and specialized skills can significantly enhance a CNC programmer’s earning potential. Many programmers pursue additional qualifications and skills to make themselves more marketable.

CNC Certification Programs

- NIMS Certification: The National Institute for Metalworking Skills (NIMS) offers certifications that validate a programmer’s skills in CNC operation, programming, and setup. Having a NIMS certification can add up to 10% to a programmer’s salary.

- Mastercam and SolidWorks Certifications: These certifications demonstrate proficiency in industry-standard CAD/CAM software and can make a programmer more valuable to potential employers.

Specialized Skills

- 5-Axis CNC Programming: Skilled CNC programmers who can program and operate 5-axis CNC machines are in high demand and often receive higher pay. These machines require more advanced skills to operate due to their complexity and versatility.

- Spindle Motor Knowledge: Being able to work with different spindle motors, such as the 24000RPM 3.2KW ER20 Water-Cooled Spindle, adds value to a programmer’s expertise and makes them more attractive to employers.

- CAM Software Proficiency: Proficiency in software like Fusion 360, Mastercam, or SolidWorks significantly impacts a CNC programmer’s value. Employers often seek programmers who can manage the entire process from CAD design to generating the final G-code.

The Earning Potential for CNC Programmer/Operators

In some facilities, the role of a CNC programmer overlaps with that of a CNC operator. A CNC Programmer/Operator is responsible for both writing the CNC code and operating the machine, ensuring that each part meets specifications.

Responsibilities of a CNC Programmer/Operator

- Programming and Setup: Writing the CNC program and setting up the machine to run the part.

- Machine Operation: Operating the CNC machine during production runs, adjusting feeds, speeds, and other variables as needed.

- Quality Control: Inspecting the machined parts to ensure they meet the required specifications.

In these hybrid roles, salaries can range between $50,000 – $70,000 per year. The versatility required for this position means employers are willing to pay more for the additional skill set.

Average CNC Programmer Salaries by Experience Level

| Experience Level | Average Annual Salary (USD) |

|---|---|

| Entry-Level (0-2 years) | $35,000 – $45,000 |

| Mid-Level (3-5 years) | $50,000 – $65,000 |

| Senior (10+ years) | $70,000 – $90,000+ |

| Programmer/Operator | $50,000 – $70,000 |

The table above provides an overview of average salaries by experience level. Note that these figures may vary depending on industry, location, and specific skills.

The Benefits of a Career in CNC Programming

Aside from competitive salaries, a career in CNC programming comes with numerous other benefits.

Job Stability and Growth

The demand for CNC programmers remains strong as the manufacturing industry grows. CNC machines are crucial for many types of production, from creating automotive components to aerospace parts. As long as there is demand for precision manufacturing, CNC programmers will continue to be in high demand.

Opportunities for Advancement

With additional experience and certifications, CNC programmers can advance to positions like CNC Machining Team Lead, Manufacturing Engineer, or Production Manager. Some even specialize in a particular area, such as 5-axis machining, leading to roles with increased responsibility and higher pay.

Diverse Work Environments

CNC programmers have the opportunity to work in various industries, each with unique projects and challenges. Whether it’s in aerospace, medical devices, or automotive, the work can be both fulfilling and rewarding.

FAQs

1. How much does a CNC programmer make per hour?

CNC programmers typically make between $20 to $40 per hour depending on their experience, skill level, and geographic location. Rates are higher for those with advanced skills or certifications.

2. Is CNC programming a good career?

Yes, CNC programming is an excellent career choice for those interested in manufacturing and technology. It offers good pay, job stability, and opportunities for growth.

3. What factors affect a CNC programmer’s salary?

Several factors impact a CNC programmer’s salary, including experience level, industry, geographic location, certifications, and specialized skills such as 5-axis CNC programming.

4. Can CNC programmers increase their salary through certifications?

Yes, obtaining certifications like NIMS, Mastercam, and SolidWorks can increase a CNC programmer’s earning potential by demonstrating advanced skills and knowledge.

5. What is the salary range for a CNC programmer/operator?

CNC programmer/operators typically earn between $50,000 – $70,000 per year, depending on their skills and experience.

Conclusion

CNC programming is a rewarding career that offers both financial stability and the opportunity for continuous learning and growth. By understanding the different factors that influence salaries—such as experience, industry, and location—you can make informed decisions about how to advance in this field. Acquiring certifications and specialized skills, such as 5-axis programming or expertise in different spindle motors, can significantly increase earning potential and career opportunities.

If you’re ready to take your CNC programming career to the next level, consider investing in high-quality spindle motors and other essential CNC components. Visit spindlemotorshop.com to explore a wide range of products designed to enhance your machining capabilities and precision. With dedication, practice, and the right tools, you can excel as a CNC programmer and achieve outstanding results in the world of manufacturing.