The CNC machining industry is crucial for modern manufacturing, and Haas is a recognized leader in providing quality CNC machines that deliver high precision, versatility, and dependability. But one of the most common questions for prospective buyers is: how much does a Haas CNC machine cost? This question is important because CNC machines are a significant investment, and understanding the costs involved can help you plan accordingly. This article will break down the pricing factors, common models, and considerations to keep in mind when purchasing a Haas CNC machine. Let’s dive into the details!

Overview of Haas CNC Machines

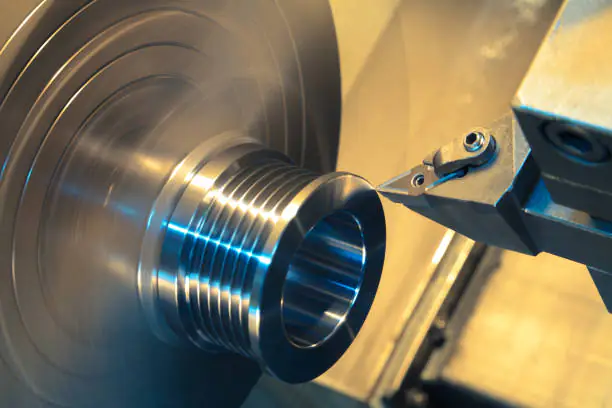

Haas Automation is one of the largest manufacturers of CNC (Computer Numerical Control) machines in the world, specializing in vertical machining centers, horizontal machining centers, rotary tables, and other automation solutions. Their machines are used widely in industries like aerospace, automotive, and medical devices. With a wide range of CNC machines, Haas caters to small shops as well as large production companies.

Haas CNC machines are known for their affordability, durability, and precision. They offer different models and configurations that can match your specific manufacturing requirements. Whether you need a vertical mill for light precision work or a 5-axis machining center for complex parts, Haas provides versatile solutions to meet production demands.

Factors That Affect the Cost of a Haas CNC Machine

The cost of a Haas CNC machine is not straightforward and depends on several factors. Let’s explore these factors that will influence the overall price:

- Machine Type: Haas offers a variety of machine types, such as vertical machining centers (VMCs), horizontal machining centers (HMCs), turning centers, and rotary tables. Each of these comes at a different price point.

- Specifications and Options: The power of the spindle, travel length, number of axes, speed, and various additional options, such as automatic tool changers or pallet changers, can significantly affect the machine’s price.

- Customization and Accessories: Options like rotary tables, tool presetters, and specific work-holding devices add to the base price.

- New vs. Used: Purchasing a used Haas CNC machine can be much more affordable than buying new, but it might come with limitations regarding warranty and support.

- Shipping and Installation: Delivery fees, installation, and other setup services may also add to the cost.

These factors should be considered while determining the final cost of purchasing a Haas CNC machine.

Price Ranges for Popular Haas CNC Models

1. Haas VF Series (Vertical Mills)

The VF series is the most popular vertical machining center from Haas, known for its versatility and reliability. Prices for the VF series vary depending on the model and specifications.

- VF-1: This is one of the entry-level models, and prices can range from $40,000 to $50,000.

- VF-2SS: The Super Speed version is suitable for high-speed milling, with costs ranging from $70,000 to $90,000.

- VF-4: This larger version, providing greater travel, is priced between $70,000 and $100,000 depending on the features.

2. Haas ST Series (Turning Centers)

Haas also offers a series of turning centers called the ST series. These are precision machines used for high-performance turning operations.

- ST-10: The smallest model in the ST series, typically starts at around $35,000.

- ST-30: More advanced turning centers with added flexibility, ranging from $70,000 to $90,000.

3. Haas UMC Series (5-Axis Machining Centers)

The UMC series is Haas’s 5-axis line, offering complete simultaneous motion and ideal for complex part production.

- UMC-500: Prices for the UMC-500 start at around $120,000, depending on additional options like high-speed spindles.

- UMC-1000: With larger capacity and increased travel, the price can go beyond $150,000.

For those looking for additional spindle options for their CNC setup, check out the ER11 Water-Cooled Spindle that offers high RPM, providing a reliable solution for complex operations.

Optional Features That Add to the Cost

1. Rotary Tables and Indexers

Adding a rotary table can convert a simple 3-axis machine into a 4 or even 5-axis setup, offering more versatility and capability. Haas offers a wide range of rotary tables that range from $5,000 to $30,000, depending on the size and complexity.

- Haas HRT160: A popular choice for adding 4-axis capability, priced around $8,000.

2. Tool Changers

Haas machines come with a basic tool changer, but upgrading to a high-speed tool changer or increasing the tool capacity can add to the cost. For instance:

- Standard 10-tool changer is included in most machines, while upgrading to a 24-tool side mount can add around $5,000 to the cost.

3. High-Speed Spindle Options

Upgrading to a high-speed spindle is another way to improve productivity, especially in applications requiring rapid material removal. Spindle options like the 15,000 RPM or 20,000 RPM versions can add between $3,000 to $8,000 to the base cost.

For example, the 2.2KW ER20 Air-Cooled Spindle available at spindlemotorshop.com offers exceptional speed for those looking to enhance their machining capabilities.

Costs Associated with Maintenance and Operation

Maintenance Costs

Maintenance is a critical aspect of owning a CNC machine. Proper maintenance helps in reducing downtime, prolonging machine life, and ensuring high productivity. The annual maintenance cost for a Haas CNC machine can vary between $1,000 to $3,000, depending on usage, maintenance type, and the parts needed for replacements.

Operational Costs

Operational costs are also significant. These costs include electricity, coolant, tooling, and operator wages. Haas CNC machines are known for their energy efficiency, but you should still factor in electricity usage which may cost around $500 to $1,500 annually, depending on your production hours.

Tooling costs depend on the type of tools used and the materials being machined. Investing in high-quality tool holders, collets, and end mills can help improve efficiency and reduce tool wear.

Is It Worth Buying a Haas CNC Machine?

Haas CNC machines are an excellent choice for those seeking high-performance and value for money. Their machines are easy to program using Haas Control, which is intuitive and operator-friendly. Additionally, Haas Factory Outlet (HFO) provides strong customer support, including training, service, and parts.

If you are running a small-to-medium-sized machine shop, Haas offers machines that can fit your budget while delivering the precision and speed necessary to compete in the industry. The versatility of VF series, the advanced features of ST series, and the complete machining solution from the UMC series make Haas a reliable option for diverse manufacturing needs.

Frequently Asked Questions

1. What is the starting price of a Haas CNC machine?

The starting price for a basic Haas CNC machine, such as the VF-1, can be around $40,000. Prices vary depending on the model and customization options.

2. Are used Haas CNC machines worth buying?

Yes, buying a used Haas CNC machine can be cost-effective. However, always ensure the machine has been well-maintained and consider the support and warranty options.

3. What are some recommended spindle upgrades for a Haas CNC?

Spindle upgrades, like the 24000RPM 0.8KW ER11 Water-Cooled Spindle found here, are great for improving speed and precision in demanding applications.

4. Does Haas offer financing options for CNC machines?

Yes, Haas offers financing options through their Haas Factory Outlet to make the purchasing process easier for businesses.

5. How often should a Haas CNC machine be serviced?

It is recommended to perform routine maintenance on a Haas CNC machine every six months, with a more detailed service once a year.

Conclusion

The cost of a Haas CNC machine can vary greatly depending on the model, size, and the additional features that are included. From vertical mills like the VF series to complex 5-axis UMC machines, there is a Haas CNC to meet a wide range of production needs and budgets. Purchasing a CNC machine is a significant investment, and understanding the associated costs will help you make an informed decision.

If you are ready to invest in a Haas CNC machine, or if you need CNC spindle upgrades to get more out of your current machine, be sure to explore the selection available at spindlemotorshop.com. With the right machine, you can increase your productivity, improve part quality, and ensure your business stays competitive in the industry.