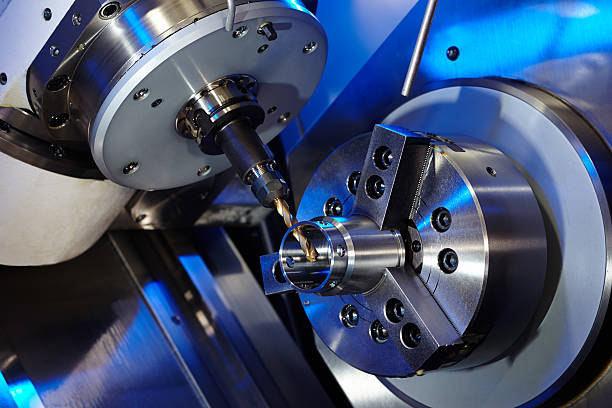

Renting a CNC machine can be a cost-effective solution for businesses or hobbyists looking to complete short-term projects without the burden of purchasing a new machine. Whether you need to create complex parts or run a small series of production, renting offers flexibility and lowers upfront costs. In this guide, we will explore the factors that influence CNC machine rental costs, the benefits of renting versus buying, and how to determine if renting is the right decision for you.

Why Rent a CNC Machine?

Advantages of Renting a CNC Machine

There are several reasons why renting a CNC machine can be an attractive option for many individuals and companies:

- Cost Savings: Renting eliminates the high initial capital investment required to buy a CNC machine. The upfront costs of purchasing a CNC machine, especially high-end models, can be prohibitive for many.

- Flexibility: Renting gives you access to the exact machine you need for your project. You can adjust the machine specifications based on the requirements of each project.

- Testing Equipment: For companies considering purchasing a CNC machine, renting provides an opportunity to test specific models before making a commitment.

- Lower Maintenance Responsibility: Maintenance costs and regular servicing are typically covered by the rental company, reducing the overall hassle and expense.

When Should You Consider Renting?

- Short-term Projects: Renting is a perfect choice for projects with a defined duration.

- Limited Budget: If the budget doesn’t permit buying a machine, renting allows you to proceed without massive initial costs.

- Skill Development: For those learning CNC machining, renting offers an opportunity to train without investing heavily in equipment that might not be fully utilized.

Factors That Influence the Cost of Renting a CNC Machine

The cost of renting a CNC machine can vary significantly based on several factors, including:

1. Type of CNC Machine

Different types of CNC machines have varying rental costs. The complexity and capabilities of the machine greatly affect the price.

- CNC Mills: Typically used for milling metal or other hard materials. The rental cost for a CNC mill ranges from $500 to $3,000 per month, depending on the machine’s specifications.

- CNC Lathes: These are generally less expensive to rent than mills. Monthly rental rates can range from $300 to $1,500.

- CNC Plasma Cutters: Plasma cutters used for cutting metal can cost between $1,000 to $4,000 per month to rent.

2. Rental Duration

The rental cost often decreases the longer you rent the machine. For example, renting for a week might be relatively expensive, whereas monthly or long-term rentals come at a discounted rate.

- Weekly Rentals: Expect higher per-day costs, ranging from $200 to $1,000 per week depending on the machine.

- Monthly Rentals: Monthly rates are typically lower, ranging between $500 and $5,000, based on the type of machine.

- Long-term Rentals: For contracts lasting 6 months or longer, discounts may be available, reducing overall rental costs.

3. Machine Specifications and Capabilities

The size, capabilities, and technology of a CNC machine are significant contributors to rental costs. Advanced machines with capabilities like 5-axis milling, high spindle speed, and automated tool changers are more expensive to rent than basic models.

- Spindle Power: Machines with higher spindle power and torque are more versatile but also command higher rental prices.

- Cutting Tool Compatibility: Some CNC machines can work with a wider variety of cutting tools, which increases their rental value.

Check out this 2.2KW ER20 Air-Cooled Spindle to learn more about spindle types that could affect CNC rental costs.

4. Equipment Accessories and Software

Some rental packages include additional accessories or software like CAD/CAM software, which can make operation easier. The availability of advanced accessories often influences the rental cost.

- Software Licensing: If you need proprietary software like Mastercam or Fusion 360, the licensing fee may be included in the rental price or charged separately.

- Table Size and Axis Movement: Larger tables and additional axis movement capabilities (such as 5-axis) also add to rental fees.

5. Maintenance and Support

Most CNC rental services include routine maintenance and technical support, which adds value but also affects the overall rental price. Machines requiring frequent calibration or having extensive warranties tend to have higher rental costs.

Cost Comparison: Renting vs. Buying a CNC Machine

Buying a CNC Machine

- High Initial Investment: Buying a CNC machine can cost anywhere from $10,000 to over $100,000, depending on its type and capabilities.

- Maintenance: Owners are responsible for all maintenance, calibration, and parts replacement, which can add significantly to the total cost of ownership.

- Depreciation: Machines depreciate over time, affecting the value of your investment if you decide to sell the equipment.

Renting a CNC Machine

- Lower Upfront Cost: Renting requires significantly less capital upfront, making it accessible for smaller businesses and projects.

- Operational Flexibility: Renting allows flexibility. If project demands change, you can switch to a different machine or adjust rental duration accordingly.

- No Depreciation: Since you don’t own the machine, you don’t face depreciation losses.

| Aspect | Buying | Renting |

|---|---|---|

| Initial Cost | High (Up to $100,000+) | Low ($300 – $5,000 per month) |

| Maintenance | Owner’s Responsibility | Handled by Rental Company |

| Depreciation | Yes, can lose value | No depreciation costs |

| Flexibility | Limited once purchased | High, can switch machines easily |

For more detailed information on CNC equipment, consider browsing CNC Spindle Motors that can help you determine the best fit for your project.

How to Rent a CNC Machine

1. Identify Your Needs

Before renting a CNC machine, it’s crucial to determine the specific needs of your project:

- Material: Are you cutting aluminum, steel, plastic, or wood? Each material requires different machine capabilities.

- Size Requirements: What are the dimensions of the workpieces you need to produce? Larger parts require a larger table.

- Precision: Do you need very tight tolerances? More advanced CNC machines offer better precision and repeatability.

2. Research CNC Rental Companies

Several companies offer CNC machine rentals. Look for those with good reviews, extensive support, and comprehensive rental packages.

- Rental Terms: Review the rental terms carefully, including the duration, maintenance provisions, and terms for returning the machine.

- Service Support: Good customer service and support are vital when renting equipment. Make sure the rental company offers on-site or virtual technical assistance.

3. Determine the Rental Period

The rental period directly impacts cost. Consider how long you need the machine and if the rental company offers discounts for longer terms.

- Short-Term: Ideal for testing machines or quick projects.

- Long-Term: Better rates are often available for rentals that span several months or longer.

4. Calculate the Costs

Costs can vary significantly depending on the machine type, duration, and accessories included.

- Initial Deposit: Most rental agreements require an initial deposit.

- Monthly Fees: These range based on machine type and rental duration. The monthly fee usually covers maintenance but may exclude wear parts.

- Delivery and Setup: Some companies charge extra for delivery, installation, and setup. Be sure to factor in these costs when planning.

To understand what makes CNC machine components essential for renting or buying, check out the 24000RPM 0.8KW ER11 Water-Cooled Spindle.

Tips for Getting the Best Deal on CNC Rentals

1. Compare Multiple Quotes

Reach out to multiple rental companies and compare their pricing. Ask if they provide any promotional discounts or price matching.

- Get Itemized Costs: Ensure that all quotes are itemized. This will help you understand what is included and if there are any hidden fees.

- Negotiate Terms: Don’t be afraid to negotiate. Rental companies may provide better rates for longer rentals or repeat customers.

2. Opt for Long-Term Rentals If Applicable

If your project spans several months, long-term rental rates are usually cheaper on a per-month basis than short-term rates.

3. Consider Machine Accessories

Renting machine accessories like specialized tool holders or spindles can be more economical than purchasing them outright.

- Tool Holders: Specialized tool holders can enhance precision and reduce setup time.

- Spindles: High-performance spindles, such as a 60000RPM Water-Cooled Spindle, can improve the quality of your finished product.

FAQs

1. How much does it cost to rent a CNC machine per day?

The daily rental cost for a CNC machine can range between $50 to $200, depending on the type and capabilities of the machine. Typically, renting by the day is more expensive compared to monthly rentals.

2. Is maintenance included in CNC machine rentals?

Yes, most CNC rental agreements include routine maintenance. However, consumables like cutting tools may need to be replaced at the renter’s cost.

3. Can I rent a CNC plasma cutter?

Yes, CNC plasma cutters are available for rent, and their costs can range between $1,000 and $4,000 per month depending on the machine’s power and specifications.

4. Are there financing options for renting CNC machines?

Some rental companies offer financing options or lease-to-own plans. These plans allow you to eventually own the equipment while spreading out payments over a period.

Conclusion

Renting a CNC machine can be a highly practical solution, particularly for those with short-term projects or for those just stepping into CNC machining without a substantial budget. It offers flexibility, reduces upfront costs, and allows you to focus on completing your project without worrying about equipment maintenance. By carefully comparing quotes, understanding the components included in the rental package, and being mindful of your specific project needs, you can make a well-informed decision that suits your requirements.

Check out various spindles and CNC parts at Spindle Motor Shop to better understand the options available and how they might benefit your projects.