Introduction

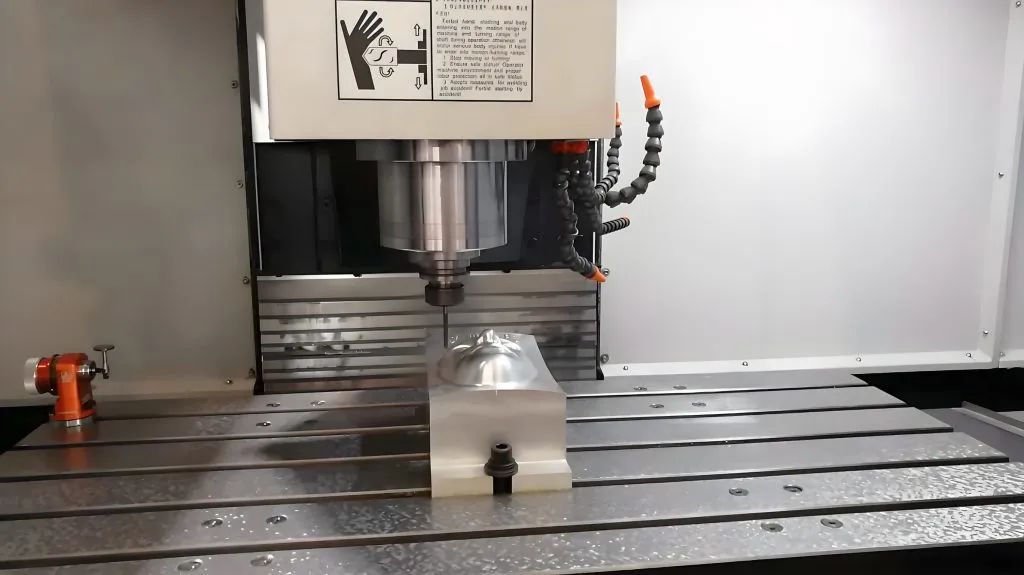

After your CNC spindle motor is disassembled or repaired, proper installation is the key to ensure that the spindle motor can operate normally. Here are the installation steps.

Cleaning and lubrication

Use gasoline to clean the inner wall of the housing and the spindle jacket to prevent impurities from entering and affecting the quality of the fit. Lubricate the bearings. High-temperature-resistant lithium-based grease or sodium-based grease is recommended to ensure lubrication.

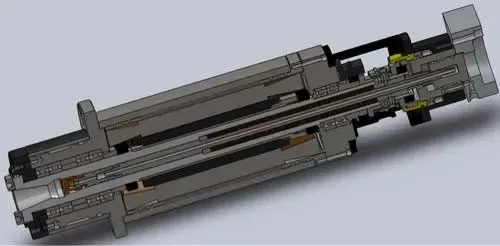

Install the bearings

First, install the rear bearing and then fix it. Secondly, the front bearing is installed, and the sleeve is machined by a nylon rod to match it to ensure that the bearing is installed firmly.

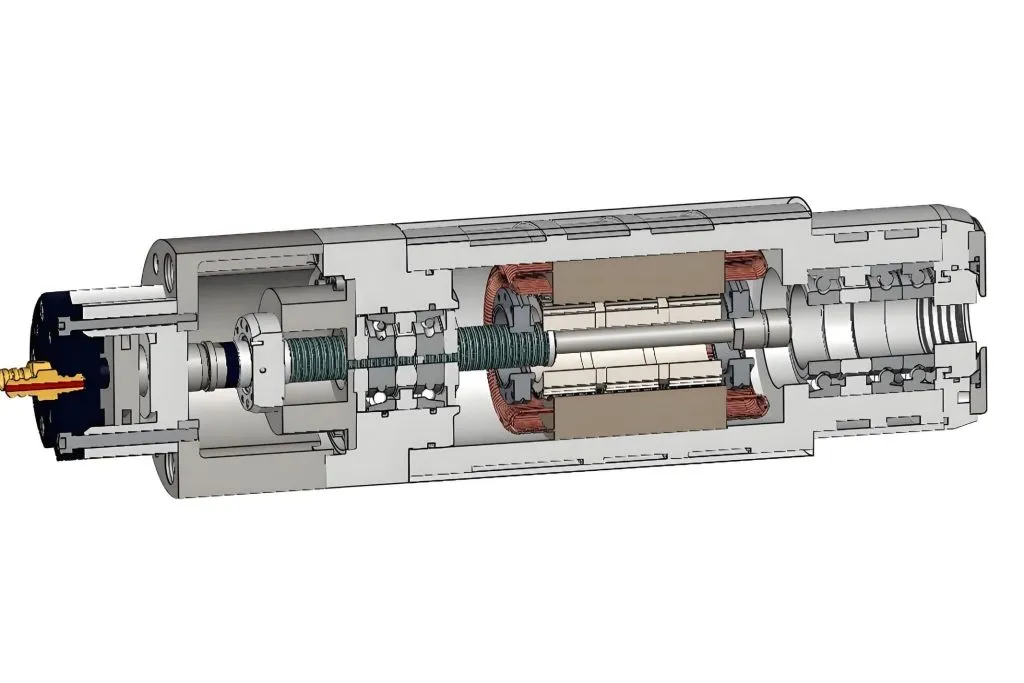

Install the spindle core.

Push the spindle from the back of the electric shaft to ensure that all bearings and covers are installed correctly. Check the alignment of each component to ensure that the spindle remains stable during operation.

Measure the spindle tool change position

For machine tools that need to measure the position of the spindle during a tool change, pay special attention to the axial extension length from the clamping to the release of the spindle. According to the thickness of the old gasket, move the spindle to the appropriate position through the operation panel and use a dial indicator to measure and adjust the gasket thickness.

Install the coupling

Finally, tighten the coupling to ensure the runout range is between 0.01 and 0.02 mm. This ensures the accuracy and stability of the spindle during operation.

Measure the spindle accuracy

After inserting the toolbar, use a dial gauge to measure the runout of the front and rear ends of the spindle to ensure that these parameters are within the specified range (usually within 0.05 mm) to ensure processing accuracy.

Conclusion

The correct CNC electric spindle disassembly and installation steps can not only extend the service life of the spindle but also ensure that the machine tool operates stably under high-precision conditions. Through the above steps, you can effectively maintain the spindle, reduce the occurrence of equipment failures, and improve processing efficiency.

Summary FAQ

1. Why do you need to measure the accuracy of the spindle when installing the spindle?

Measuring the accuracy of the spindle can ensure the accuracy and quality of the processing and avoid errors caused by spindle runout or poor alignment.

2. How to determine whether the bearing needs to be replaced?

Through cleaning and inspection after disassembly, if the bearing shows obvious signs of wear or damage, it is recommended that it be replaced in time to avoid affecting the normal operation of the spindle.

3. What are the requirements for the selection of lubricating oil?

Choosing high-temperature resistant lubricants, such as lithium-based grease or sodium-based grease, can ensure stable bearing lubrication at high temperatures and extend its service life.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.