CNC machine operators play a crucial role in modern manufacturing, transforming raw materials into precise parts used in everything from automotive components to aerospace technology. If you’re considering a career in the field, you may be wondering how to become a CNC machine operator. This comprehensive guide will walk you through the steps required to launch a successful career as a CNC machine operator, covering skills, training, job opportunities, and more. Whether you’re just starting out or making a career switch, this guide is for you.

What is a CNC Machine Operator?

Defining the Role

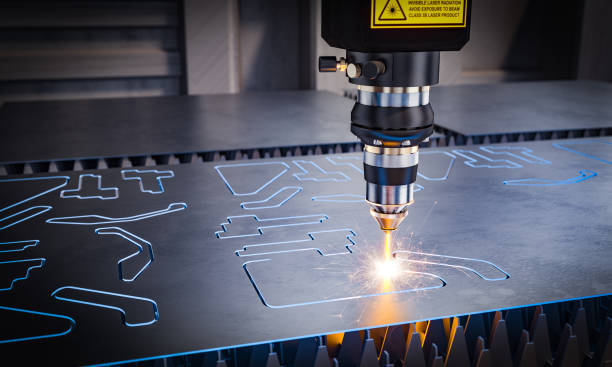

A CNC (Computer Numerical Control) machine operator is responsible for operating machines that use programmed software to produce parts from materials like metal, plastic, or wood. Unlike CNC machinists, who are more involved with programming and setup, CNC operators focus on running and monitoring these machines to ensure they are functioning correctly.

CNC machine operators load materials, initiate the program, and oversee the entire process to ensure that each part meets the required specifications. They also make minor adjustments and ensure that safety standards are met throughout the process.

Key Responsibilities

A CNC machine operator is tasked with several responsibilities, including:

- Loading Materials: Preparing raw materials and loading them into the CNC machine.

- Running CNC Programs: Initiating programs to produce the required parts.

- Monitoring Machine Performance: Ensuring that the CNC machine is operating properly.

- Quality Control: Measuring finished parts to ensure they meet the required specifications.

- Basic Maintenance: Performing minor maintenance to keep machines in good working order.

Skills Needed to Become a CNC Machine Operator

Technical Skills

To excel as a CNC machine operator, you need several technical skills:

- Mechanical Aptitude: A basic understanding of how machines and tools work is crucial.

- Blueprint Reading: Operators must be able to read technical drawings to understand how parts should be made.

- Basic Programming Knowledge: While operators don’t usually write programs, understanding G-code can help troubleshoot issues.

- Math Skills: A good understanding of basic math, particularly geometry, helps in measuring and setting up parts.

Soft Skills

- Attention to Detail: CNC machining is all about precision, and operators need to be meticulous.

- Problem-Solving: Issues will arise, and a good CNC operator should be able to quickly address problems.

- Dependability: Manufacturers need operators who can run machines reliably without constant supervision.

Hands-On Experience

Gaining hands-on experience is crucial for becoming proficient in CNC machine operation. Working alongside experienced machinists helps new operators learn the nuances of machine setup, troubleshooting, and maintenance.

To gain practical experience, quality tools are essential. Consider our 2.2KW ER20 Air-Cooled Spindle for consistent and precise machine performance.

Steps to Becoming a CNC Machine Operator

1. Obtain a High School Diploma or GED

The first step towards becoming a CNC machine operator is to earn a high school diploma or GED. High school courses such as math, computer science, and shop classes can provide a strong foundation.

2. Enroll in CNC Training Programs

Many community colleges and trade schools offer CNC training programs that can take anywhere from a few weeks to several months. These programs teach you the basics of machine operation, safety protocols, and how to read blueprints.

| Institution Type | Program Duration | Focus |

|---|---|---|

| Community College | 6 months – 1 year | CNC fundamentals, blueprint reading |

| Trade School | 2 – 6 months | Hands-on machine operation |

| Apprenticeship Programs | 1 – 2 years | In-depth practical experience |

3. Gain Hands-On Experience through Apprenticeships

Apprenticeships offer an excellent way to gain hands-on experience while earning a wage. They typically last 1-2 years and provide exposure to different types of CNC machines and real-world manufacturing processes.

4. Obtain Certification

While not always required, getting certified can greatly enhance your career prospects. Certifications such as the NIMS (National Institute for Metalworking Skills) CNC Machine Operator certification demonstrate your competency to employers.

- NIMS Certification: Covers machine setup, operation, and basic programming skills.

- HAAS CNC Certification: Ideal for those who work with HAAS CNC machines.

5. Apply for CNC Machine Operator Jobs

Once you have the required skills and certifications, you can begin applying for jobs. Modern manufacturing facilities, aerospace companies, and automotive parts manufacturers are just a few industries in need of skilled CNC machine operators.

Types of CNC Machines You May Operate

1. CNC Milling Machines

CNC milling machines use rotating cutting tools to remove material from a workpiece. Operators are responsible for selecting the right tool, loading the material, and overseeing the cutting process.

2. CNC Lathes

A CNC lathe spins the material while a stationary tool shapes it. Lathes are often used for parts that are symmetrical, like screws or pins. CNC operators need to ensure the material is loaded properly and the machine is functioning smoothly.

3. CNC Routers

CNC routers are used to cut and shape wood, plastic, and other softer materials. CNC operators working with routers may be involved in furniture making or other wood-related manufacturing.

4. Multi-Axis CNC Machines

Multi-axis CNC machines are capable of moving cutting tools in multiple directions, allowing for the creation of more complex parts. These machines require a greater degree of expertise to operate.

Tools and Equipment for CNC Machine Operators

CNC Tools

- Cutting Tools: Inserts, end mills, and drills are essential for material removal.

- Collets and Chucks: Used for securing the workpiece during machining.

CNC Spindles

Spindles are crucial components in CNC machines that determine the speed and precision of cuts. Using a reliable spindle, like our 24000RPM 1.5KW ER16 Water-Cooled Spindle, ensures optimal machine performance and reduces wear.

Daily Life of a CNC Machine Operator

Typical Workday

A CNC machine operator’s day typically starts with a review of production schedules and machine assignments. Once the machine is set up with the appropriate tools and materials, the operator will:

- Load the Material: This involves placing the raw material in the machine’s fixture or chuck.

- Run the CNC Program: Operators initiate the pre-loaded program, ensuring it follows the blueprint specifications.

- Monitor and Adjust: Throughout the machining process, operators make necessary adjustments to ensure precision.

- Quality Control Checks: Using calipers, micrometers, and other measuring tools, operators verify the dimensions of completed parts.

- Maintenance: Performing routine maintenance, such as lubricating components or replacing worn tools.

Safety Considerations

Safety is a priority in CNC machining. Operators must always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, and follow proper safety protocols to prevent accidents.

Challenges Faced by CNC Machine Operators

Precision and Accuracy

One of the biggest challenges for CNC operators is maintaining the precision required by the job. Small deviations can lead to parts being out of tolerance, which can be costly for manufacturers.

Repetitive Tasks

While the work is rewarding, it can also be repetitive. This means CNC operators must maintain focus throughout their shift to avoid mistakes.

Machine Downtime

Machine downtime is an issue that operators often face. Troubleshooting issues and getting the machine back up and running quickly is crucial for maintaining production schedules.

Career Growth Opportunities

CNC Machinist

After gaining experience as a CNC operator, you could progress to become a CNC machinist. This role involves more responsibilities, such as setting up machines, programming, and making more complex adjustments.

CNC Programmer

With additional training, CNC operators can move into CNC programming roles. This role requires a deeper understanding of CAD/CAM software and the ability to write custom programs for CNC machines.

CNC Supervisor

Experienced CNC operators may also move into supervisory roles, overseeing other operators, ensuring that production schedules are met, and maintaining quality standards.

Tips for Success as a CNC Machine Operator

- Practice Regularly: The more time you spend operating CNC machines, the more proficient you’ll become.

- Stay Updated: CNC technology evolves, so staying updated with new tools and methods is key.

- Take Further Training: Enrolling in courses to learn CNC programming or additional machining techniques can open new career doors.

- Communicate Well: Being able to communicate with CNC machinists and supervisors helps in ensuring that projects run smoothly.

FAQs

1. How long does it take to become a CNC machine operator?

It usually takes 3-6 months if you enroll in a trade school program or community college. Apprenticeships may take longer, providing more comprehensive training.

2. Is CNC machine operation a good career?

Yes, becoming a CNC machine operator offers job stability, growth opportunities, and competitive pay, especially in the manufacturing sector.

3. Do I need certification to be a CNC operator?

While certification is not always required, it can significantly improve your employability and earning potential.

4. How much do CNC machine operators earn?

The average hourly wage for a CNC machine operator in the United States ranges from $15 to $25 depending on experience and location.

5. What industries hire CNC machine operators?

Aerospace, automotive, medical device manufacturing, and general manufacturing are the top industries that hire CNC machine operators.

Conclusion

Becoming a CNC machine operator is a rewarding path that offers job security, good pay, and growth opportunities. From learning the fundamentals in trade school to gaining hands-on experience in a manufacturing setting, there are multiple ways to enter this field and build a successful career. The demand for CNC operators continues to grow as industries like aerospace, automotive, and medical devices expand, making now an ideal time to begin this career journey.

Using high-quality tools, such as our 24000RPM 1.5KW ER16 Water-Cooled Spindle, ensures that you are prepared for success in any CNC operation. By following the steps outlined in this guide, you can build the skills and experience