Building a CNC router table is a highly rewarding project that combines creativity with precision engineering. Whether you’re a hobbyist, a small business owner, or a DIY enthusiast, having your own CNC router table can make it easier to create complex parts and bring your designs to life. In this guide, we’ll cover everything you need to know about building a CNC router table, from selecting materials to assembling the machine.

What is a CNC Router Table?

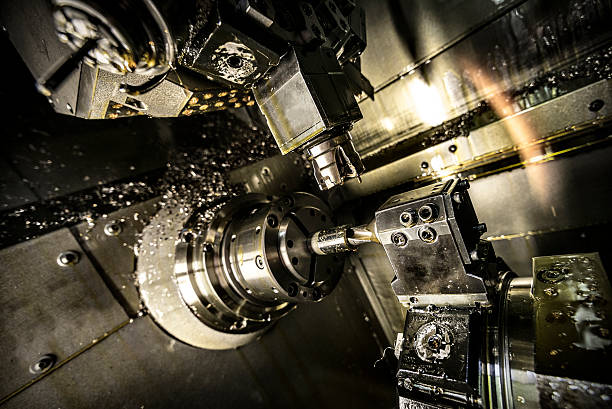

A CNC (Computer Numerical Control) router table is a machine that can precisely cut and shape materials like wood, plastic, and metal by following programmed instructions. It consists of a flat work surface (the table), cutting tools, and a computer that directs the movement of the cutting tool.

CNC router tables are commonly used for woodworking, metalworking, and custom fabrication. With the right tools and a proper understanding of the components, you can build a CNC router table that fits your needs, whether you’re a professional or just starting out in the world of CNC machining.

Why Build Your Own CNC Router Table?

Building your own CNC router table has many advantages. Not only can you save on costs, but you can also customize the machine to meet your specific requirements. Here are some reasons to consider building your own CNC router table:

- Cost Savings: Purchasing a pre-built CNC router can be expensive, especially for larger models. By building your own, you can save significantly.

- Customization: You have complete control over the design, size, and features of the CNC router table.

- Learning Experience: Building a CNC router table is an excellent way to learn about the components of CNC machines and how they work together.

Essential Components of a CNC Router Table

Before diving into the building process, it’s important to understand the key components that make up a CNC router table:

- Frame: The structural foundation of the machine. The frame must be sturdy to prevent vibrations and ensure precision.

- Gantry: The horizontal structure that holds the spindle and allows movement across the table.

- Spindle Motor: The cutting tool that performs the actual material removal.

- Linear Rails: These are tracks that guide the movement of the gantry.

- Stepper Motors and Drivers: These components control the movement of the machine along the X, Y, and Z axes.

- Controller: The brain of the CNC machine, which interprets G-code and sends commands to the motors.

You can learn more about spindle motors, which are crucial for achieving precision, on CNC Spindle Motors.

Step-by-Step Guide to Build a CNC Router Table

Step 1: Design Your CNC Router Table

The first step is to design the CNC router table. You can use software like Fusion 360 or SolidWorks to create a 3D model of your machine. When designing the table, consider factors such as:

- Size of the Work Area: Determine the size of the work area you need based on the type of projects you’ll be working on.

- Material: Choose materials like steel or aluminum for the frame to ensure stability.

- Type of Rails: Select between linear rails or V-wheels based on your budget and accuracy requirements.

Pro Tip: A larger work area allows for greater flexibility but requires a more rigid frame to maintain accuracy.

Step 2: Gather Materials and Tools

Once you have a design in mind, it’s time to gather the materials. Here is a basic list of materials you will need:

| Material | Purpose |

|---|---|

| Steel/Aluminum | Frame and gantry |

| MDF | Work surface |

| Stepper Motors | Control movement |

| Spindle Motor | Cutting tool |

| Linear Bearings | Smooth gantry movement |

| Drive System | Belts, screws, or rack and pinion |

In addition to materials, you will need tools like drills, wrenches, and a welder to assemble the components.

Step 3: Build the Frame

The frame is the backbone of your CNC router table. It must be rigid enough to prevent any vibrations that could impact the accuracy of your cuts.

- Use steel tubing or extruded aluminum for the frame, depending on the budget and desired weight.

- Make sure all corners are properly aligned and welded if using steel. For aluminum, connectors are typically used.

Note: Ensure that the frame is level to prevent any inaccuracies during operation.

Step 4: Assemble the Gantry and Rails

The gantry holds the spindle and moves along the X-axis and Y-axis. Use linear bearings and rails to guide this movement.

- Mount the linear rails on both sides of the frame. These will allow the gantry to move smoothly across the X and Y axes.

- Attach the gantry to the rails and ensure it moves freely without any obstruction.

You can check out some linear rail systems and spindle options on Spindles for CNC Router.

Step 5: Install the Spindle Motor

The spindle motor is the cutting tool of the CNC router, and it’s crucial for the quality of the finished product. You can choose between water-cooled or air-cooled spindles based on your requirements.

- Water-Cooled Spindles: Ideal for longer run times as they prevent overheating.

- Air-Cooled Spindles: Easier to set up and maintain but may not handle prolonged usage as efficiently as water-cooled models.

For a powerful option, consider the 24000RPM 3KW ER20 Water-Cooled Spindle, which offers high precision and durability.

Step 6: Set Up the Electronics

The electronics are what make your CNC router operate. The key components include stepper motors, motor drivers, limit switches, and the controller.

- Stepper Motors and Drivers: Mount the stepper motors and connect them to the gantry. The drivers control the power and direction of the motors.

- Controller: This component takes G-code commands from the computer and converts them into signals that drive the motors.

You can either use an off-the-shelf CNC controller board or build your own using Arduino and CNC shield.

Step 7: Wiring and Cable Management

Proper wiring and cable management are crucial for safety and reliability.

- Use cable chains to route the wires for the stepper motors and spindle motor. This will prevent the wires from getting tangled during operation.

- Make sure all electrical connections are secure, and use cable ties to keep everything organized.

Step 8: Calibrate the CNC Router

Once everything is assembled, it’s time to calibrate your CNC router. Calibration ensures that the router moves accurately and cuts precisely.

- Check the Alignment: Make sure the gantry is level and moves freely along the rails.

- Set Up Limit Switches: Limit switches help prevent the machine from moving beyond its intended range.

- Test Movements: Use G-code to move the router along the X, Y, and Z axes to ensure smooth operation.

Step 9: Test Run and Adjustments

Before starting any production work, it’s essential to conduct a test run. Run the machine without any material to ensure all parts are moving as they should.

- Dry Run: Perform a dry run to check for any mechanical or electrical issues.

- Adjustments: Make necessary adjustments if there are any misalignments or if the spindle is not holding its position properly.

Step 10: Start Cutting

Once you’re confident in your CNC router’s performance, you can start cutting. Begin with simple projects to get a feel for the machine.

- Choose the Right Bit: Different materials require different cutting bits. For wood, use end mills with two or four flutes.

- Set the Speed and Feed: Adjust the spindle speed and feed rate based on the material.

For more information on CNC bits and tools, you can visit CNC Router Spindles.

Maintenance Tips for CNC Router Table

To keep your CNC router table in optimal condition, regular maintenance is crucial:

- Clean the Rails: Dust and debris can accumulate on the linear rails. Make sure to clean them regularly.

- Lubricate Moving Parts: Proper lubrication of the linear bearings and lead screws will reduce wear and extend the life of your machine.

- Inspect Wiring: Regularly inspect the wiring for any signs of wear or loose connections.

Frequently Asked Questions

1. What materials can I cut with a CNC router table?

A CNC router table can cut a variety of materials, including wood, plastic, aluminum, and brass. The type of spindle and cutting bit used will determine what materials can be processed.

2. Is building a CNC router table cheaper than buying one?

Yes, building a CNC router table can be significantly cheaper than purchasing a pre-built one. However, it requires a good understanding of mechanics and electronics.

3. What type of spindle motor should I use?

The type of spindle motor depends on your usage. For frequent and extended usage, water-cooled spindles are recommended, whereas air-cooled spindles are suitable for occasional use.

4. Can I build a CNC router table without welding?

Yes, you can use extruded aluminum with connectors instead of welding. This option is particularly useful for hobbyists who do not have access to welding equipment.

5. How accurate can a homemade CNC router table be?

The accuracy of a homemade CNC router table depends on the quality of components and assembly precision. With proper calibration and high-quality components, it is possible to achieve an accuracy within 0.1mm.

Conclusion

Building a CNC router table is a rewarding experience that allows you to create precise and complex parts right in your workshop. By understanding the essential components, gathering the right materials, and following a step-by-step assembly process, you can build a machine that meets your specific needs. Whether you’re building it for hobbyist projects or for small-scale manufacturing, a CNC router table is a valuable tool that will expand your capabilities.

To learn more about spindle motors and other CNC components, make sure to visit spindlemotorshop.com. With a well-built CNC router, the possibilities are endless, and you can take your ideas from concept to reality with ease.