Introduction

Checking the health of the CNC electric spindle is essential to ensure machining quality, machining efficiency and extend the life of the spindle. Here are some basic inspection steps and methods for reference only

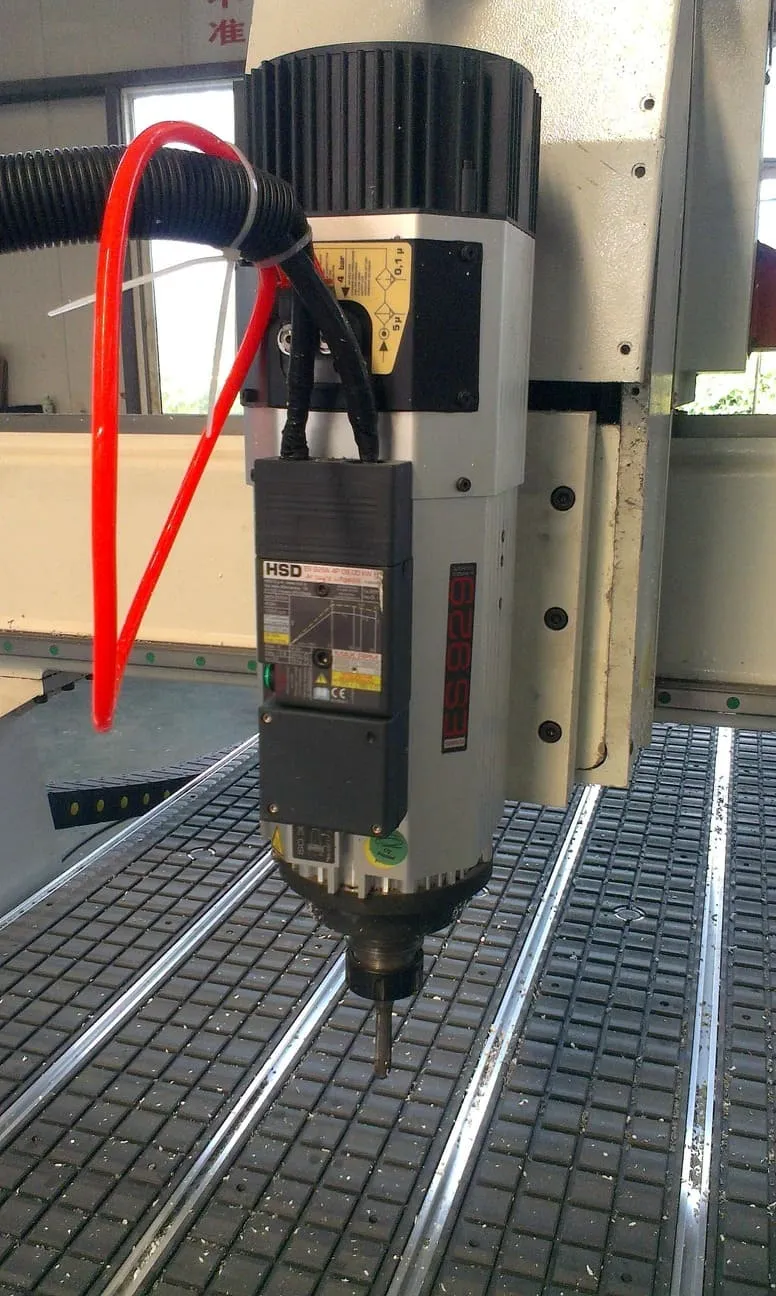

Appearance inspection

Carefully inspect the electric spindle for visible damage, dents, cracks or abnormal wear. This can help you discover potential spindle problems and avoid the damage becoming more serious.

Sound inspection

Listen for abnormal noise: When the electric spindle is running, pay attention to any abnormal noise, such as friction, knocking or whistling. These sounds may be signs of problems with the internal parts of the spindle and need to be handled and repaired in time.

Check the bearing condition

Check whether the bearing is worn or damaged, and observe whether it runs smoothly. You can judge whether the rotation is smooth and stable by listening to whether the bearing is running or manually rotating the shaft.

Axial and radial runout inspection

Use the spindle test rod to measure and check the axial and radial runout of the spindle to ensure that it is working within the allowable error range. This helps maintain machining accuracy and avoids affecting the quality of the final product.

Temperature inspection

After a long period of operation, check whether the temperature of the electric spindle is average. Abnormally high temperatures may cause equipment wear, damage or performance degradation, which needs to be dealt with in a timely manner.

Maintenance and Cleaning

Regularly clean the chips, dust and other impurities on the electric spindle to prevent contamination and overheating, keep the electric spindle clean, and help extend its service life.

Conclusion

Through the above inspection and maintenance steps, you can fully understand the health of the CNC spindle and take appropriate measures to ensure the stability and efficiency of the processing process. Regular inspection and maintenance can not only extend the service life of the equipment but also improve the processing accuracy and reduce the failure rate.

Summary FAQ based on the article

1. Why should the CNC spindle be inspected regularly?

Regular inspections can detect potential problems, avoid fault expansion, ensure the normal operation and processing accuracy of the equipment, and improve the service life of the equipment.

2. How to check the electrical system of the electric spindle?

Check the power cord status and perform an insulation resistance test and motor resistance test to ensure the normal operation of the electrical system.

3. What should be paid attention to when inspecting the bearing?

Check the wear or damage of the bearing, determine whether it is running smoothly, and replace or repair it if necessary.

4. How to monitor the temperature of the electric spindle?

A temperature sensor or infrared thermometer is used to monitor the operating temperature of the electric spindle to ensure that it is within the normal range.

5. What is a dynamic balance check?

The dynamic balance check is to ensure that the electric spindle maintains a good balance at high speed through testing to reduce vibration and improve processing accuracy.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.