Cleaning your CNC machine is crucial for maintaining its performance, extending its lifespan, and ensuring precise machining results. CNC machines are built to handle complex operations, but dirt, debris, and general wear can cause significant problems if they aren’t addressed regularly. This comprehensive guide will teach you how to effectively clean your CNC machine, from basic maintenance tasks to in-depth cleaning routines, so you can ensure your machine stays in optimal working condition.

Why Cleaning Your CNC Machine Is Important

Regularly cleaning your CNC machine serves multiple purposes. The most important reason is to prevent downtime due to clogs, jams, or decreased accuracy. Dust, chips, and general grime can lead to reduced performance and even costly damages if they find their way into sensitive parts of the machine.

Benefits of a Clean CNC Machine

- Prolonged Lifespan: Routine cleaning reduces the wear on components, resulting in a longer operational lifespan.

- Improved Precision: Dust, grime, and residue can interfere with the machine’s accuracy, leading to errors and defects in the final product.

- Reduced Maintenance Costs: Preventative maintenance, including cleaning, helps reduce the need for costly repairs, ultimately saving you money.

To explore more on how to enhance your CNC system, you can visit our CNC Spindles page.

Tools You Need for Cleaning a CNC Machine

Before you start cleaning, ensure you have the right tools to avoid any accidental damage to the machine’s components. The following are the basic tools you need:

Recommended Cleaning Supplies

| Tool | Purpose |

|---|---|

| Lint-Free Cloth | Wiping down surfaces |

| Vacuum Cleaner | Removing dust and metal chips |

| Soft Brush | Cleaning sensitive areas |

| Isopropyl Alcohol | Disinfecting metal surfaces |

| Coolant Oil Filter | Maintaining coolant clarity |

Safety gear like gloves, protective goggles, and a dust mask are also crucial to protect yourself from any potential hazards while cleaning the CNC machine.

Step-by-Step Guide to Cleaning a CNC Machine

1. Power Down and Disconnect

The first and most crucial step is to power down the machine and disconnect it from the main power supply. This step is non-negotiable as it prevents electric shock or accidental activation during the cleaning process.

2. Remove Chips and Debris

After every machining session, it is essential to remove metal chips and debris. Use a vacuum cleaner or a specialized chip removal tool to suck up chips from hard-to-reach areas and corners. This helps prevent buildup that can damage the machine’s moving parts.

Tip: Using a shop vacuum with a narrow nozzle can be especially helpful for removing stubborn chips lodged in tight spaces.

If you want to learn more about maintaining different CNC components, check out our CNC Spindle Motors guide.

3. Wipe Down All Surfaces

Take a lint-free cloth dampened with isopropyl alcohol to wipe down all accessible surfaces of the CNC machine. This will remove grime and leftover coolant, leaving the machine clean without leaving any residue. Make sure you dry off all surfaces properly to avoid rust.

4. Clean the Coolant System

The coolant system plays an important role in the efficiency of a CNC machine. Dirty coolant can affect machine performance and lead to corrosion.

- Replace Coolant Regularly: Check your manufacturer’s manual for coolant replacement frequency, and make it a habit to replace it as recommended.

- Clean the Coolant Tank: Remove the tank, empty the old coolant, and clean any sludge or deposits before refilling.

Learn more about the 24000RPM 0.8KW ER11 Water-Cooled Spindle, which uses advanced cooling systems for better machining.

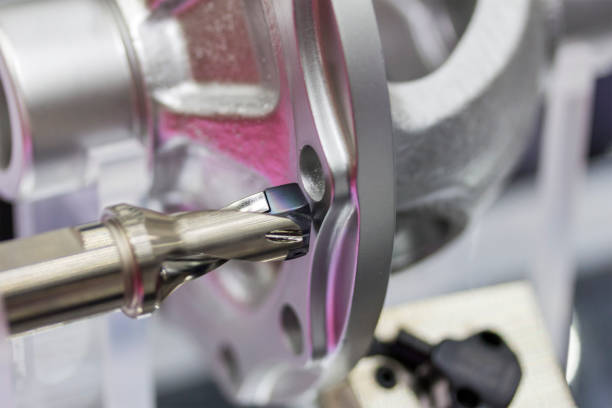

Cleaning the Spindle of Your CNC Machine

The spindle is the heart of a CNC machine, and keeping it clean ensures accurate machining and longer tool life.

1. Inspect the Spindle

Visually inspect the spindle for any signs of wear, residue buildup, or damages. Use a clean cloth to remove any visible dust from the spindle’s surface.

2. Clean the Spindle Nose

Using a soft brush, clean the spindle nose and tool holder surfaces. This area is prone to collecting dirt and debris, which can lead to concentricity issues during machining if not properly maintained.

Quote: “The spindle is the engine of your CNC machine; treat it well, and it will provide precise cuts for years.” – CNC Maintenance Expert, John Matthews

3. Lubricate After Cleaning

After cleaning, it’s vital to lubricate the spindle to keep it moving smoothly and reduce friction. This step not only extends the spindle’s lifespan but also enhances the quality of your cuts.

Recommended Spindle Maintenance Products

Cleaning the Linear Rails and Ball Screws

1. Linear Rails

The linear rails are essential for the accurate movement of the CNC machine components along their axes. Regular cleaning is crucial for smooth operations.

- Wipe Down: Use a clean, dry cloth to remove dust and particles from the linear rails.

- Inspect for Wear: Check for signs of wear such as scoring or pitting that might affect the machine’s accuracy.

2. Ball Screws

The ball screws are vital for maintaining the accuracy of the CNC machine. They need consistent cleaning and lubrication to function properly.

- Wipe and Lubricate: After wiping down the ball screws, apply a suitable lubricant. Regular lubrication reduces friction and prevents excessive wear.

What to Avoid While Cleaning

While cleaning a CNC machine, you should avoid using certain tools and methods to prevent damage:

- Compressed Air: Using compressed air might push dirt and debris further into the machine, which can lead to internal damage.

- Water: Direct water application can lead to rust or corrosion, damaging the machine over time.

- Harsh Chemicals: Strong solvents can corrode sensitive components or strip necessary lubricants.

Common Mistakes During CNC Machine Cleaning

1. Inadequate Cleaning Frequency

Waiting too long between cleanings can lead to the accumulation of debris, which may result in operational issues. Develop a regular cleaning routine that includes daily, weekly, and monthly maintenance.

2. Neglecting the Control Panel

The control panel is just as important as other mechanical components. Clean the control panel regularly to prevent dust accumulation that could impair button function.

3. Failing to Replace Filters

Filters play a critical role in keeping contaminants away from the machine’s sensitive parts. Replace coolant and air filters as needed to maintain optimal performance.

Frequently Asked Questions

1. How often should I clean my CNC machine?

Ideally, you should clean your CNC machine after every shift to maintain peak performance. In addition, perform a more thorough cleaning on a weekly or monthly basis, depending on usage.

2. Can I use soap and water to clean my CNC machine?

No, using soap and water directly is not advisable because it can cause rust and corrosion. Use isopropyl alcohol or specialized machine cleaners instead.

3. What happens if I don’t clean my CNC machine regularly?

Failing to clean your machine can lead to a buildup of debris, negatively affecting accuracy and possibly causing damage to moving parts.

4. Are specialized cleaning agents necessary?

While specialized agents are not strictly required, it is advisable to use non-corrosive and lint-free materials to avoid damage.

5. How do I maintain my CNC spindle?

To maintain the spindle, conduct regular inspections, apply appropriate lubrication, and keep tool holder surfaces clean. Listen for any unusual noises that may indicate issues.

Conclusion

Properly cleaning your CNC machine is essential to maintaining its efficiency and longevity. By cleaning components like the spindle, linear rails, and control panels, you can prevent costly breakdowns and ensure consistently high-quality work. This routine is not only about boosting performance but also about safeguarding your investment.

If you’re looking for additional information or products that can help you maintain your CNC machine, visit our CNC Spindles Page. Keeping your CNC machine clean will improve performance, enhance precision, and reduce the risks of expensive repairs.