Introduction

Keeping your CNC spindle clean is essential for precision, longevity, and smooth operation. Neglecting spindle maintenance can result in performance degradation, higher repair costs, and even machine downtime. This guide will walk you through the process of cleaning a CNC spindle, ensuring that your machining center stays in top shape. Whether you’re a seasoned professional or just starting, understanding how to maintain your spindle will save you both time and money.

What is the Role of a CNC Spindle?

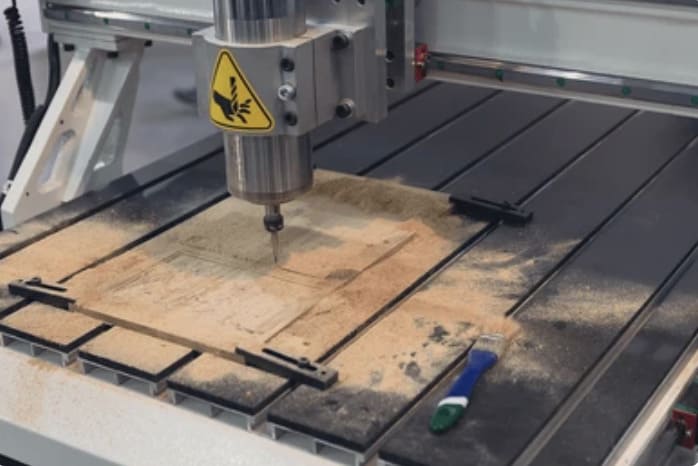

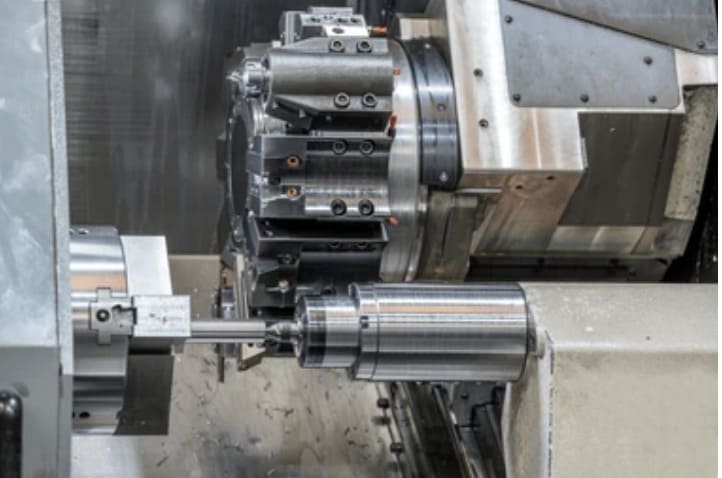

The CNC spindle is the heart of your machine. It is responsible for rotating the cutting tool or workpiece, providing the speed and torque needed to machine parts. Without a well-functioning spindle, your CNC machine cannot perform the high-precision tasks required in many industries.

Spindles come in various types and sizes, depending on the machine’s requirements and the processed materials. Understanding its role helps appreciate why regular maintenance, particularly cleaning, is crucial for maintaining spindle efficiency.

Different Types of CNC Spindles and Their Uses

Are all CNC spindles the same?

No, different CNC spindles serve different purposes. They are categorized based on their power ratings, speed capabilities, and the specific material they’re designed to cut. Some of the most common types include:

- Belt-driven spindles: Ideal for lighter materials.

- Direct-drive spindles: Preferred for high-precision machining tasks.

- Gear-driven spindles: Used when cutting harder materials like steel.

Knowing the type of spindle you’re working with is essential when performing maintenance and cleaning, as each type has unique care requirements.

Why is Regular Spindle Maintenance Important?

Routine spindle maintenance, particularly cleaning, ensures smooth operation and extends the lifespan of the spindle. A clean spindle reduces the risk of vibration, tool misalignment, and even overheating. Without proper cleaning, debris can clog the spindle bearings, resulting in reduced machine performance and costly repairs.

By scheduling regular cleanings, you can avoid sudden machine downtime, protect the spindle shaft, and ensure that the bearings are functioning smoothly.

Tools and Materials Needed for Cleaning

Before starting the spindle cleaning process, make sure you have the right tools:

- Non-abrasive cloths for wiping down the spindle.

- Compressed air to blow away small debris.

- Lubricants for the spindle bearings.

- Cleaning solutions designed for CNC spindles.

Using proper tools ensures that you don’t accidentally damage the spindle during cleaning.

| Tool | Purpose |

|---|---|

| Non-abrasive cloths | Wipe surfaces without scratching. |

| Compressed air | Remove debris from small crevices. |

| CNC spindle cleaner | Remove grease and grime from spindle surfaces. |

| Lubricants | Ensure bearings remain lubricated after cleaning. |

Step-by-Step Guide to Cleaning Your CNC Spindle

What is the right way to clean a CNC spindle?

Here’s a step-by-step guide to cleaning your CNC spindle:

- Turn off and isolate the machine: Always start by turning off the CNC machine and disconnecting it from the power source.

- Remove spindle components: Disassemble the necessary parts such as tool holders or collets for easy access to the spindle.

- Clean the spindle shaft and bearings: Use a non-abrasive cloth and spindle cleaner to wipe down the spindle shaft. Be careful around the bearings to avoid damaging them.

- Use compressed air: Blow away any debris or fine particles trapped in small areas.

- Lubricate the spindle: After cleaning, apply lubricant to ensure smooth operation and longevity.

Following these steps will help you maintain your spindle’s performance and prevent unwanted downtime.

How Often Should You Clean a CNC Spindle?

The frequency of spindle cleaning depends on how often the machine is used and the type of material being machined. For high-precision tasks like mold making or aerospace components, cleaning should be more frequent due to the demands of tight tolerances.

How can improper cleaning affect spindle performance?

Improper cleaning or neglect can lead to a buildup of material, which can affect spindle speed and accuracy. It’s best to clean the spindle after any heavy machining operation or at least once a week for general usage.

Common Mistakes to Avoid During CNC Spindle Maintenance

Mistakes during spindle cleaning can have long-term consequences. Here are some common pitfalls:

- Using the wrong cleaning products: Avoid abrasive chemicals or cloths that can damage the spindle’s surface.

- Skipping lubrication: After cleaning, failing to lubricate the spindle can lead to friction, causing wear on the bearings.

- Not properly reassembling: Always ensure every part is reassembled securely after cleaning to avoid spindle misalignment.

Avoiding these errors can help extend the lifespan of your CNC spindle.

What are the Risks of Neglecting CNC Spindle Cleaning?

Neglecting spindle cleaning can lead to severe performance issues, including:

- Overheating: A clogged spindle can overheat, causing damage to internal components.

- Increased wear and tear: Dirt and debris increase friction, wearing down the spindle over time.

- Poor machining quality: If the spindle isn’t properly maintained, it can result in inaccurate cuts and reduced precision.

Case Studies: Before and After Cleaning Analysis

Does cleaning really impact spindle performance?

Yes! Here are a couple of real-world examples showcasing the benefits of regular cleaning:

- Before cleaning: A manufacturer experienced significant vibration issues and inconsistent tool changes. After cleaning, these problems were eliminated.

- After cleaning: A woodworking CNC machine saw improved tool life and better surface finishes after a thorough spindle cleaning and lubrication.

These examples highlight the importance of maintaining a clean and functional spindle.

Conclusion

Maintaining a clean CNC spindle is not just about prolonging the machine’s life—it’s essential for delivering high-quality results. By following this guide and incorporating regular cleaning into your maintenance routine, you’ll ensure optimal spindle performance and avoid unnecessary downtime. Whether you’re working with wood, metal, or composites, a well-maintained spindle is key to achieving accuracy and efficiency.

Key Takeaways:

- A CNC spindle requires regular maintenance for optimal performance.

- Proper cleaning helps prevent overheating, vibration, and wear.

- Always use the right tools and materials for spindle cleaning.

- Consistent spindle care improves both the quality of your machining and the lifespan of your machine.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.