Introduction

The balance of the CNC spindle is crucial to the operation efficiency and accuracy of CNC machine tools. To ensure that the spindle can run smoothly at high speed and avoid vibration and damage caused by imbalance, spindle dynamic balancing debugging is required.

Static balancing method

The static balancing method is mainly used to adjust the balance of the spindle in a static state. Its basic principle is to keep the spindle balanced in a horizontal position by adding or removing an appropriate amount of mass.

Place the spindle horizontally

First, place the spindle horizontally on two supporting points so that it can rotate freely.

Adjust the mass distribution

By adding or removing an appropriate amount of mass, the spindle can maintain a horizontal position without external interference.

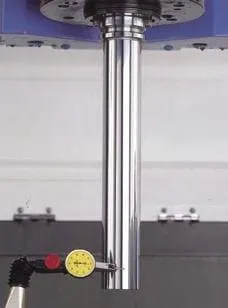

Measure with a static balancer

Use a static balancer or a hook to measure the balance of the spindle. If an imbalance is found, further adjust the mass distribution until balance is achieved.

Dynamic balancing method

The dynamic balancing method is a method of detecting imbalance by rotating the spindle and taking corresponding measures to achieve balance.

Fix a tension band on the spindle

First, fix a tension band on the spindle, and then install the spindle on the balancing machine.

Start the balancing machine for measurement

Start the balancing machine and let the spindle start to rotate. The balancing machine will measure the unbalanced vibration of the rotating spindle and derive the direction and size of the imbalance.

Adjust according to the measurement results

According to the measurement results of the balancing machine, choose the appropriate method to achieve dynamic balancing, such as adding or deleting mass, changing the mass distribution.

Steps for dynamic balancing debugging of the spindle

Determine the spindle type and parameters

Before debugging, you first need to determine the type and parameters of the spindle to be debugged and understand the design requirements of the spindle.

Prepare debugging tools and instruments

Prepare the required debugging tools and instruments, such as static balancing instruments, hooks, balancing machines, etc.

Prepare a spindle brake balance test card

Make a spindle brake balance test card to record the debugging parameters and results.

Perform static balancing debugging

Place the spindle horizontally

Place the spindle horizontally and fix it with support points.

Measure the balance state

Use a static balancing instrument or hook to measure the balance state of the spindle and record the imbalance.

Adjust the mass distribution

According to the measurement results, add or delete the appropriate amount of mass until the spindle reaches a balanced state.

Confirm whether the design requirements are met

Re-measure the balance state of the spindle to confirm whether it meets the design requirements.

Perform dynamic balancing debugging

Install the spindle on the balancing machine

Install the spindle on the balancing machine and fix the tension belt on the spindle.

Start the balancing machine for measurement

Start the balancing machine, make the spindle start to rotate, and measure its unbalanced vibration.

Adjust according to the suggestions

According to the debugging suggestions of the balancing machine, choose a suitable method for dynamic balancing, such as adjusting the mass and changing the mass distribution.

Conclusion

Spindle dynamic balancing debugging is a key step to ensure the smooth operation of the machine tool spindle, improve equipment efficiency and extend service life. The unbalanced state of the spindle can be effectively eliminated by combining the static balancing method with the dynamic balancing method. In actual operation, it is necessary to carefully record and analyze the debugging results, and make adjustments as needed to ensure that the balance performance of the spindle meets the design requirements. At the same time, the operator must pay attention to safety and comply with relevant operating procedures to ensure the smooth progress of the debugging work.

Summary FAQ based on article

1. What is the basic principle of static balancing?

The static balancing method adds or removes an appropriate amount of mass to keep the spindle balanced in a horizontal position.

2. How does the dynamic balancing method achieve spindle balance?

The dynamic balancing method detects imbalance by rotating the spindle and adjusts the mass distribution according to the measurement results to achieve spindle balance.

3. What are the preparations for spindle dynamic balancing debugging?

The preparations include determining the spindle type and parameters, preparing debugging tools and instruments, and making spindle brake balance test cards.

4. How to confirm whether the spindle balance state meets the design requirements during the debugging process?

After static and dynamic balancing debugging, re-measure the balance state of the spindle and confirm whether it meets the design requirements.

5. What should be done when the debugging results do not meet the design requirements?

If the debugging results do not meet the design requirements, further adjustments and re-measurements are required until the requirements are met.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.