Introduction

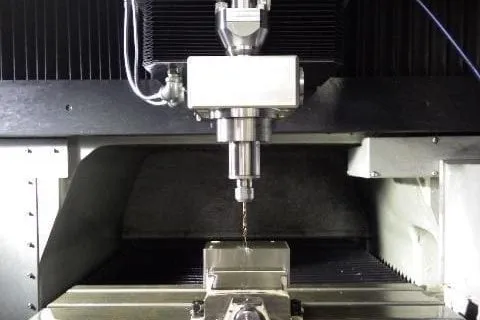

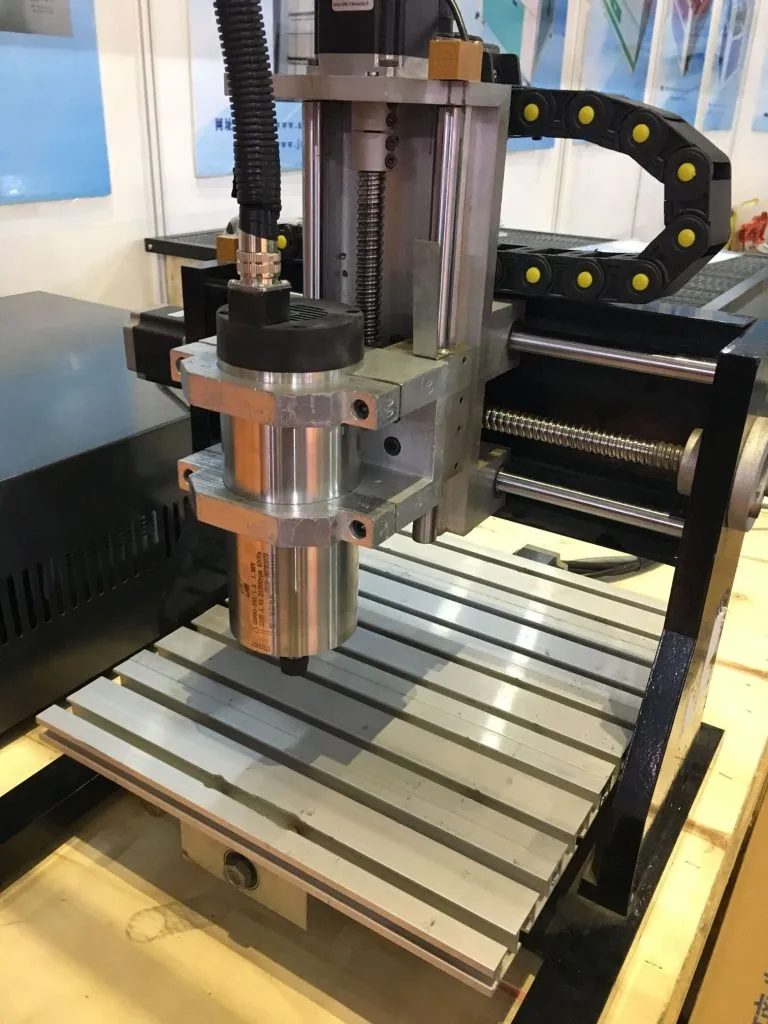

In the daily maintenance of CNC machine tools, removing and installing the CNC spindle is a key step. Correct operation can ensure the equipment’s normal operation and extend the electric spindle’s service life. This guide will introduce in detail how to remove and install the CNC spindle to help you perform effective maintenance work.

Disconnect the power supply

First, make sure the machine power supply is disconnected. This step is critical to avoid accidental startup of the machine during operation and major safety accidents, ensuring the safety of the operator.

Remove accessories

Remove all accessories from the spindle, including tools and fixtures, and if it is a water-cooled spindle, remove the cooling device connections (such as cooling water pipes and air pipes) and power cords. Make sure that nothing obstructs the spindle removal process.

Record the position

Before disassembly, mark the position of the spindle and its components. Please ensure they can be restored to their original position when reinstalling. This will help maintain accurate stability when reinstalling.

Remove internal components

Remove the spindle front cover, bearing cover or support sleeve, which may involve a disc spring block, washers and various fastening nuts. Be careful when operating to avoid damaging these precision parts.

Remove bearings

For bearings with interference fit, you may need to heat the spindle or use special tools to remove the bearings slowly and evenly. Pay special attention to protecting the bearings from damage during this process.

Conclusion

Correct CNC disassembly steps can not only extend the service life of the spindle but also avoid secondary damage to the machine tool under certain conditions. You can disassemble the spindle and avoid disassembly stories through the above steps.

Summary FAQ

1. Why is disconnecting the power supply the first step?

Disconnecting the power supply ensures the operator’s safety and avoids accidental startup during disassembly and installation.

2. Why must you record the position when disassembling the electric spindle?

Recording the position ensures that the precise position is maintained during reinstallation to avoid equipment failure caused by improper installation.

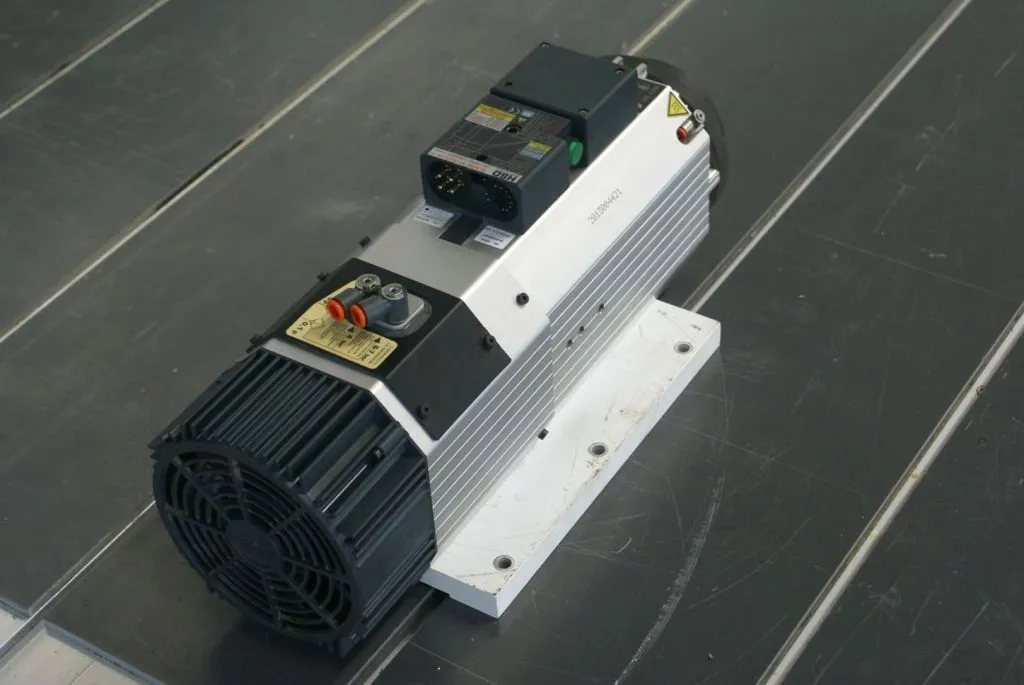

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.