In the world of precision manufacturing, finding skilled CNC machinists is a crucial step to ensure the smooth and efficient operation of your CNC machines. The demand for talented CNC machinists is high, and the right individual can make all the difference in your production process, ensuring parts are created accurately and on time. In this guide, we’ll cover every aspect of how to find CNC machinists, including the key skills to look for, where to find them, and the recruitment strategies that will attract the best talent. If you’re looking to answer the question, “How to find CNC machinists?” then you’ve come to the right place.

Understanding the Role of a CNC Machinist

What is a CNC Machinist?

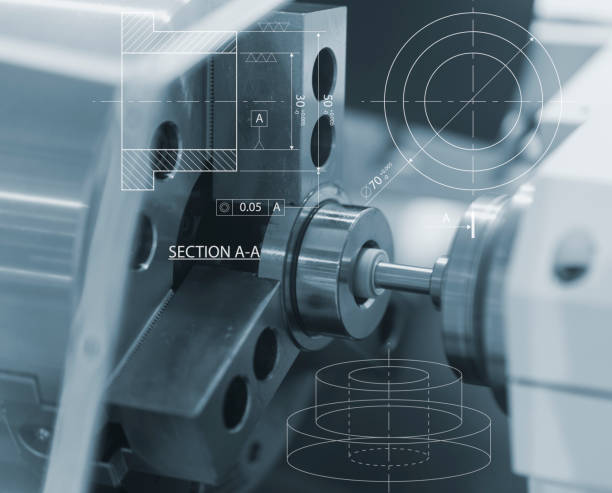

A CNC machinist is a highly skilled professional responsible for operating and maintaining CNC machines. These machines are used to cut, shape, and finish materials like metal, wood, and plastic with extreme precision. CNC machinists program the CNC machine based on detailed blueprints and specifications, ensuring that each part meets the required standards.

Key Responsibilities of a CNC Machinist

- Programming the Machine: Using G-code to instruct the machine on movements, speeds, and cuts.

- Setting Up the Machine: Installing tools, fixtures, and materials before starting a job.

- Quality Control: Inspecting finished parts to ensure they meet the required specifications.

- Troubleshooting and Maintenance: Addressing any issues that arise and maintaining the CNC machine to ensure proper function.

Skills Required for CNC Machinists

To find a good CNC machinist, look for candidates with the following skills:

- Technical Proficiency: A good understanding of CNC programming, machine operation, and reading blueprints.

- Attention to Detail: Precision is key in CNC machining, and machinists need to maintain high accuracy levels.

- Problem-Solving Ability: CNC machinists often need to troubleshoot and solve problems quickly.

- Experience with CNC Tools: Knowledge of CNC tools, including spindles like our 60000RPM 1.2KW ER11 Water-Cooled Spindle, can be an indicator of valuable hands-on experience.

Where to Find Skilled CNC Machinists

1. Technical Schools and Community Colleges

Many technical schools and community colleges offer CNC training programs. These institutions produce graduates with a fundamental understanding of CNC operation, programming, and maintenance. Establish partnerships with these schools to create a pipeline of potential recruits.

2. Job Boards and Recruitment Websites

Posting on general job boards such as Indeed, LinkedIn, or specialized manufacturing job sites like MachinistJobs can yield great candidates. Make sure your job posting is well-crafted, with clear details about the skills and experience required.

3. Industry-Specific Forums and Websites

Online forums related to CNC machining, like Practical Machinist, and websites that cater to the manufacturing industry are excellent resources for finding CNC machinists. These platforms often have dedicated job boards and community areas where machinists congregate and discuss job opportunities.

4. Apprenticeship Programs

Consider offering apprenticeships to attract new talent. These programs can be a cost-effective way to find and train skilled CNC machinists. Apprenticeships give you the opportunity to shape new workers to fit your specific requirements.

5. Recruitment Agencies Specializing in Manufacturing

If you’re struggling to find suitable candidates on your own, consider partnering with recruitment agencies that specialize in manufacturing and CNC machining. These agencies have existing talent pools and can help you find the right fit more quickly.

Qualities to Look for in a CNC Machinist

Hiring the right CNC machinist goes beyond just technical skills. Here are some of the qualities to prioritize:

- Strong Work Ethic: CNC machining requires focus and dedication. A machinist must be committed to delivering quality work on time.

- Team Player: In most manufacturing environments, CNC machinists work alongside engineers, other machinists, and operators. Good teamwork is essential.

- Adaptability: CNC technology is always evolving, and a good machinist should be able to learn new software, tools, and methods as they emerge.

Writing an Effective Job Description for CNC Machinists

To attract the best CNC machinists, you need to create a compelling job description. Here’s what to include:

Job Title

Use a clear and descriptive title like CNC Machinist – Milling and Turning Specialist or CNC Operator for High-Precision Machining.

Job Summary

Provide an overview of the position, including the types of CNC machines used (e.g., 2-axis lathes, 5-axis milling machines), and what products or parts they’ll be working on.

Responsibilities

List the specific tasks that the machinist will be responsible for. Be detailed but avoid being overwhelming. Include tasks like:

- Programming CNC machines using G-code.

- Setting up machines with the correct tooling and fixtures.

- Conducting quality checks and inspections.

Required Skills and Qualifications

Specify the level of experience you are looking for, such as:

- 3-5 years of CNC machining experience.

- Familiarity with CAD/CAM software like Fusion 360.

- Experience with spindle maintenance, such as the 24000RPM 1.5KW ER11 Water-Cooled Spindle.

Benefits

Mention the benefits that come with the job, like competitive pay, health insurance, paid leave, and career development opportunities. Benefits are often a deciding factor for job seekers.

Screening and Interview Process for CNC Machinists

Finding the right CNC machinist involves a structured interview and assessment process to evaluate their skills, experience, and fit for your team.

1. Resume Screening

Look for relevant keywords like CNC machining, CAD/CAM, and specific machine types. Pay attention to the machinist’s experience level, previous employers, and certifications.

2. Skill Assessment Test

Conduct a practical test to evaluate the machinist’s knowledge and skills. This could include:

- Programming a simple part on CAM software.

- Setting up a CNC machine and running a trial part.

- Identifying and solving a common machining problem.

3. Behavioral Interview

In the interview, ask questions that assess both technical knowledge and behavioral traits. Sample questions include:

- Can you describe a challenging CNC machining project you’ve worked on and how you solved any problems that arose?

- How do you ensure safety and precision while working?

- Describe a time when you had to adapt to a new type of CNC machine or technology. How did you approach learning it?

Training and Development for CNC Machinists

Once you’ve found a CNC machinist, retaining them and keeping their skills up to date is the next step. Here’s how to do that:

1. On-the-Job Training

Provide structured on-the-job training for new hires. This helps them become familiar with the specifics of your machinery, tools, and production methods.

2. Continuous Education

Encourage machinists to take up courses in CAD/CAM software, advanced machining techniques, or new types of machinery. Many online platforms offer training that can fit around a busy work schedule.

3. Skill Development Workshops

Invest in workshops or seminars on new CNC tools or methods. For example, learning about newer spindle models like our 2.2KW ER20 Square Air-Cooled Spindle with Flange can improve their productivity.

FAQs

1. What qualifications do I need to look for when hiring a CNC machinist?

Look for qualifications such as experience in CNC programming, familiarity with CAD/CAM software, and hands-on experience with different types of CNC machines.

2. How can I ensure a CNC machinist is skilled in troubleshooting?

During the interview, ask them to describe a situation where they had to troubleshoot a problem with a CNC machine and how they solved it. Practical tests can also help assess these skills.

3. Is it important for a CNC machinist to have knowledge of spindle maintenance?

Yes, spindles are a key part of CNC machines, and proper maintenance is essential for smooth operation. Knowledge of spindle maintenance, like working with a water-cooled spindle, can be a great asset.

4. Where can I find CNC machinists with experience in high-precision work?

You can find experienced machinists through industry-specific job boards, recruitment agencies, or by networking with trade schools that offer advanced CNC machining courses.

5. How much does a skilled CNC machinist typically earn?

The average salary for a CNC machinist depends on experience and location, but typically ranges from $45,000 to $70,000 per year, with more experienced machinists earning higher wages.

Conclusion

Finding the right CNC machinist is a challenging but rewarding task. By understanding the skills required, utilizing the right recruitment channels, and offering competitive job descriptions, you can attract talented professionals who will add significant value to your business. Remember, a skilled machinist isn’t just an operator—they’re the backbone of efficient and precise production.

To ensure success in CNC machining, always invest in continuous training and the right tools for the job. Quality components, such as high-performance spindles like our 60000RPM 1.2KW ER11 Water-Cooled Spindle, can enhance productivity and lead to better results in the long run.

With the right strategy, you can build a team of talented CNC machinists capable of taking your manufacturing processes to the next level, ensuring both precision and efficiency.