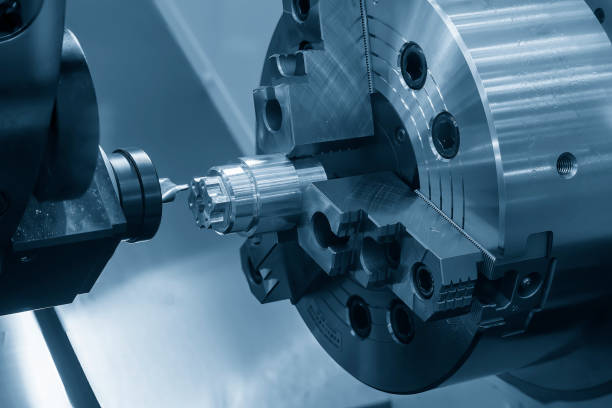

CNC machining is a crucial aspect of modern manufacturing, providing the precision needed to create everything from automotive parts to medical devices. To excel in the field of CNC machining, obtaining a CNC certification is an excellent step that can open up multiple job opportunities and establish your credibility as a skilled machinist. In this article, we will explore the journey to becoming a certified CNC operator, the benefits it brings, and the specific skills required to succeed in this field.

What is CNC Certification?

CNC certification is an official recognition that indicates your knowledge and proficiency in operating CNC machines. These certifications cover a wide range of skills—from understanding the programming language (like G-code) to setting up machines and performing quality checks. Whether you are an aspiring CNC machinist or an experienced professional looking to boost your career, a CNC certification helps validate your expertise.

There are several bodies that offer CNC certifications, such as the National Institute for Metalworking Skills (NIMS), Manufacturing Skill Standards Council (MSSC), and local technical schools that provide CNC-specific courses. Certifications typically cover topics like machine setup, CNC programming, safety protocols, and quality control.

Why Pursue CNC Certification?

1. Increased Job Opportunities

The demand for skilled CNC machinists is high in industries like automotive, aerospace, and construction. Obtaining a CNC certification significantly boosts your chances of getting hired by proving your skillset to potential employers.

- Job Security: Certified machinists are often favored by employers because they bring validated skills to the table.

- Better Pay: CNC machinists with certification generally earn higher wages compared to non-certified operators.

2. Proof of Skill and Knowledge

CNC certification offers employers a clear indication that you possess the technical knowledge and hands-on skills needed to operate CNC machinery efficiently.

- Industry Standards: Certifications are designed to meet industry standards for CNC machinists, ensuring that your skills are in line with current technology and practices.

- Recognition: Having a certification from a recognized body like NIMS makes it easier for employers to evaluate your skills compared to someone without formal credentials.

3. Career Growth

If you are already working as a CNC operator, certification can provide opportunities for promotion into more advanced roles, such as CNC programming, shop management, or even CNC instructor positions.

“Certification not only proves your skill but also shows your commitment to professional growth, making you stand out in the competitive job market.”

Types of CNC Certifications

1. Entry-Level Certifications

For those just starting out in the field, entry-level certifications offer basic CNC training. These certifications cover topics like basic machine operation, reading blueprints, and tool handling.

- NIMS Entry-Level Certification: This is ideal for beginners who want to understand the fundamentals of CNC machining.

- MSSC Certified Production Technician (CPT): This certification includes a module on CNC operations, giving candidates a well-rounded introduction to manufacturing skills.

2. Advanced Certifications

Advanced certifications are for those who want to expand their skills into programming and machine setup.

- NIMS CNC Programming Certification: This certification focuses on programming skills, including writing G-code and using CAD/CAM software.

- CAM Certification: Certifications in Computer-Aided Manufacturing (CAM) are beneficial for CNC machinists who want to learn about creating toolpaths and generating CNC programs.

3. Specialized Certifications

Certain industries require specialized CNC knowledge. For example, the aerospace industry often requires additional certifications that cover quality control and working with specific metals like titanium or Inconel.

- AS9100 Certification: Often required for CNC machinists in the aerospace industry, this certification focuses on quality management systems.

Steps to Get CNC Certified

1. Enroll in a CNC Training Program

The first step to becoming a certified CNC machinist is to enroll in a CNC training program. This could be through a community college, technical school, or specialized online courses.

- Hands-On Training: Ensure the program provides hands-on training, as practical experience is crucial in CNC machining.

- Use of CNC Machines: Look for programs that give access to various CNC machines, such as mills, lathes, and routers.

2. Gain Practical Experience

While learning the theory is essential, practical experience is just as important. Many programs offer internships or apprenticeships, allowing you to work directly under experienced machinists and understand how to apply classroom knowledge in real-world settings.

- Internships: Participating in an internship at a local manufacturing company will help you build skills under real-world conditions.

- Apprenticeship: An apprenticeship program may last 6 months to 2 years and is an excellent way to gain a broad set of skills.

3. Take Certification Exams

Once you’ve completed your training and gained some experience, it’s time to take the certification exam. Exams typically include both a written component and a practical exam.

- Written Exam: Tests your understanding of CNC programming, safety protocols, and the functionality of various CNC machines.

- Practical Exam: Requires candidates to perform tasks like machine setup, programming, and machining a part according to given specifications.

4. Additional Certifications

Once you’ve achieved your entry-level certification, consider pursuing additional certifications in areas like CNC programming or CAD/CAM. These certifications can make you more marketable and provide you with additional career opportunities.

Skills Required for CNC Certification

To succeed as a certified CNC machinist, you’ll need a blend of technical skills and hands-on abilities. Here’s a breakdown of the essential skills required:

1. Understanding of CNC Programming

CNC programming is a vital skill. It involves writing G-code, which dictates the actions of the CNC machine.

- G-code and M-code: Knowing how to write and interpret these codes is essential.

- CAD/CAM Software: Experience with software like Fusion 360 or Mastercam helps in generating CNC programs.

2. Machine Operation Skills

CNC operators must know how to set up and run CNC machines effectively. This includes tool setup, selecting the appropriate feed rate, and ensuring the part meets quality standards.

3. Blueprint Reading

Reading technical blueprints is critical for machinists to understand the exact specifications required for each part.

- Dimensions and Tolerances: Understanding dimensions and tolerances ensures the parts are machined correctly and fit together as intended.

4. Safety Knowledge

Working with CNC machinery involves numerous safety risks. Knowing safety procedures is essential to avoid accidents.

- PPE: Personal Protective Equipment, such as safety goggles and gloves, must always be used.

- Emergency Procedures: Operators should be trained to know where emergency stop buttons are and how to use them in a crisis.

Where to Get CNC Certified

1. Technical Schools and Community Colleges

Many technical schools and community colleges offer CNC certification programs. They provide a comprehensive education in CNC machining, including hands-on practice with CNC equipment.

- Courses Offered: Programs may include basic CNC operations, CNC milling, and lathe operation.

- Local Options: Look for colleges near you that offer certification programs. These are often more affordable than private institutions.

2. Online Courses

For those who need flexibility, online CNC courses offer a convenient way to prepare for certification.

- LinkedIn Learning and Udemy: Both offer courses on CNC machining, covering programming, setup, and basic operation.

- NIMS E-learning: The National Institute for Metalworking Skills offers online courses that can be used as preparation for their certification exams.

3. On-the-Job Training Programs

Some companies offer on-the-job training that leads to certification. This is an excellent way to learn while you earn.

- Manufacturer-Specific Training: Some companies provide training specific to the machines they use, which can also lead to certification.

Cost of CNC Certification

The cost of CNC certification varies depending on the level of certification and the institution offering it. Here is a breakdown:

- Entry-Level Certification: Usually costs between $200 – $500 for the course and exam fees.

- Advanced Certification: Certifications like NIMS CNC Programming can cost upwards of $1000, especially if additional coursework is required.

- Financial Aid: Some schools offer scholarships or financial aid options for those looking to get certified.

Frequently Asked Questions About CNC Certification

1. How long does it take to get CNC certified?

The length of time depends on the level of certification. Entry-level certification typically takes 6 months, while advanced certifications can take 1-2 years, including hands-on training.

2. Can I get CNC certified online?

Yes, several organizations offer online CNC courses that prepare you for certification exams. However, hands-on experience is often required, which might necessitate visits to a local workshop.

3. Do I need prior experience to enroll in a CNC certification course?

No, many entry-level courses are designed for complete beginners. However, having some familiarity with manufacturing or machining processes is beneficial.

4. How much does a certified CNC machinist make?

Salaries vary by location and experience, but certified CNC machinists typically earn between $45,000 to $65,000 annually. Advanced certifications can lead to even higher pay.

5. Is CNC certification worth it?

Absolutely. CNC certification can significantly improve job prospects, earning potential, and career growth opportunities, making it a worthwhile investment.

Conclusion

Getting CNC certified is a powerful step towards building a rewarding career in manufacturing. It demonstrates that you have the skills and expertise required to operate CNC machines efficiently, program them accurately, and maintain high quality in production. Whether you’re just starting out or looking to expand your capabilities, the right CNC certification can unlock new opportunities and help you stand out in a competitive job market.

If you’re considering a future in CNC machining, it’s also important to equip yourself with the right tools. For those seeking precision and reliability, spindles play a crucial role in CNC machining. Check out Spindle Motor Shop for a wide selection of CNC spindle.