How to Get CNC Experience

CNC (Computer Numerical Control) machining is an essential skill in many modern industries, particularly in manufacturing, aerospace, and automotive sectors. Becoming a proficient CNC machinist requires a combination of formal education, hands-on experience, and ongoing practice. In this guide, we’ll explore different ways to gain CNC experience, from enrolling in specialized programs to gaining on-the-job training, and how you can build the knowledge and skills needed to succeed in this field. Whether you’re starting from scratch or aiming to enhance your current capabilities, this guide will offer actionable steps to accelerate your CNC experience.

Understanding CNC Machining: What Does a CNC Machinist Do?

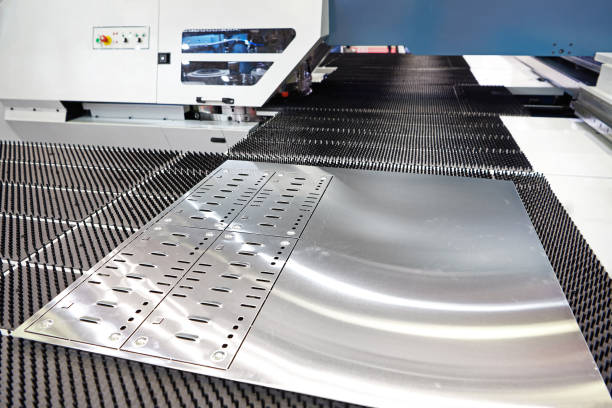

A CNC machinist is responsible for operating, setting up, and maintaining CNC machines that are used to manufacture precision components. These machines follow pre-programmed commands to cut, shape, and form materials such as metal and plastic. CNC machinists must have a mix of technical skills and knowledge to read blueprints, set machine parameters, select the appropriate tools, and troubleshoot any problems that arise during operation.

Key Skills Needed to Become a CNC Machinist

- Technical Skills: A strong understanding of mechanical systems is essential. This includes understanding how CNC machines work, such as the interaction between spindle motors, linear guides, and cutting tools. Learning about different types of spindle motors, like the 2.2KW ER16 Air-Cooled Spindle, can help you understand how different parts contribute to the overall machining process.

- Blueprint Reading: CNC machinists must read and interpret technical drawings and blueprints to manufacture the correct parts. This skill is fundamental in ensuring the machine follows the proper instructions for precision cutting.

- Computer Skills: Since CNC machines are computer-controlled, basic knowledge of G-code programming and CAD/CAM software is crucial. G-code is the language that tells the machine how to move and what actions to perform.

- Problem-Solving: CNC machinists frequently face unexpected issues like tool wear or misalignment, and they need strong problem-solving skills to correct these issues quickly.

These skills can be gained through a combination of hands-on experience, formal education, and specialized training courses. Gaining a firm grasp of the basic CNC components, including various spindle motors like the 800W ER11 Air-Cooled Spindle, will help you become more comfortable with CNC systems.

Enroll in a Trade School or CNC Program

The most straightforward way to begin your journey toward becoming a CNC machinist is by enrolling in a trade school or technical college that offers CNC-related courses.

Choosing the Right School

When looking for a suitable school, consider institutions that have a strong reputation in industrial technology. Trade schools typically offer programs that focus on hands-on training, allowing students to gain real-world experience on state-of-the-art CNC machines. A trade school certificate program typically lasts between 12 to 24 months, depending on the level of certification.

Look for programs that cover the following areas:

- G-Code Programming: Learning how to write and modify G-code, the machine language for CNC, is fundamental.

- Tool Setup and Operation: Hands-on experience with setting up spindle motors, installing cutting tools, and calibrating the machine.

- CAD/CAM Software: Learning to use computer-aided design and manufacturing software helps to create toolpaths that will be used by CNC machines.

Completing a program from a recognized trade school or technical college will provide you with a high school diploma or GED equivalent that showcases your expertise in CNC machining, making you more employable in the industry.

Getting Hands-On Experience During Your Studies

During your time at a trade school, prioritize hands-on practice over theoretical learning whenever possible. Getting comfortable using high-quality spindle motors like the ER11 1.5kw 24000rpm Water-Cooling Spindle will enhance your understanding of different tools available for CNC applications.

Apprenticeships: Learning on the Job

One of the most effective ways to gain CNC experience is through apprenticeships. Many companies offer apprenticeship programs that allow you to learn from experienced machinists while earning a wage. These programs typically last one to four years and give you hands-on experience with the latest CNC technologies.

Benefits of an Apprenticeship

- Real-World Experience: Learning directly in the workplace allows you to understand the day-to-day challenges and how to troubleshoot problems effectively.

- Mentorship: Having an experienced machinist as a mentor can provide invaluable guidance, helping you avoid common pitfalls and learn advanced techniques more quickly.

- Exposure to Different CNC Systems: During your apprenticeship, you will likely work on various types of CNC machines, from routers to mills, and use different spindle motors like the 7.5KW ER32 Air-Cooled Spindle, providing you with a well-rounded skillset.

To find an apprenticeship, reach out to local manufacturing companies or consult trade school career services. Be prepared to demonstrate your passion for CNC machining and your willingness to learn.

Gaining CNC Experience Through On-the-Job Training

If you are already working in a factory or manufacturing environment, there might be opportunities to gain CNC experience through on-the-job training (OJT). Companies often promote promising employees to CNC operator positions after they’ve demonstrated aptitude and a good work ethic.

Tips for Making the Most of OJT

- Show Initiative: Express your interest in CNC machining to your supervisor, and ask for opportunities to shadow more experienced machinists.

- Learn the Basics on Your Own: Before officially starting CNC training, familiarize yourself with G-code programming and CAD software. This knowledge will give you an advantage during training.

- Practice on Simple Parts: When beginning, ask to practice on simpler parts to build your confidence before taking on more complex projects.

With dedication, on-the-job training can be an excellent way to transition from a general manufacturing role into a CNC machinist role, allowing you to build your skills and knowledge over time.

Self-Learning Through Online Courses and Resources

In today’s digital world, many reputable platforms offer online CNC courses that can help you gain the necessary skills from the comfort of your home. Websites like Coursera, edX, and even YouTube have courses taught by experienced professionals.

Online Learning Tips

- Start with the Basics: Focus first on learning how to read blueprints, G-code, and basic machine operations. Understanding these fundamentals will make advanced topics easier.

- Invest in Simulation Software: CNC simulation software allows you to practice programming and visualize the machine’s operations without the need for a physical machine. This is a great way to learn how the CNC system interprets G-code.

- Hands-On Practice is Key: Try to find access to a CNC machine, even if it’s at a local maker space or through a friend’s workshop. Practicing on real machines will solidify your understanding.

For those unable to access CNC machines directly, gaining familiarity with different CNC components such as spindle motors through reputable resources like spindlemotorshop.com is invaluable.

Building a CNC Machine from a Kit

Another unique way to gain hands-on CNC experience is by building your own CNC machine from a kit. This can help you learn not only how to operate CNC machinery but also how the various components interact.

Benefits of Building Your Own CNC

- In-Depth Understanding: You will learn about every component of a CNC machine, including spindle motors, linear guides, and controllers.

- Practical Skills: Assembling a CNC machine requires mechanical aptitude and troubleshooting skills, which are essential for any CNC machinist.

Building a CNC machine gives you practical insight into machine setup and calibration—skills that are directly transferable to working on professionally manufactured CNC equipment. Consider using a 24000RPM 3.2KW ER20 Water-Cooled Spindle to understand different spindle options for CNC machines.

Frequently Asked Questions

1. How long does it take to become proficient in CNC machining?

It typically takes about one to two years of hands-on training or formal education to become proficient. This timeline may vary depending on the complexity of the tasks and individual aptitude.

2. What is the difference between a CNC operator and a CNC machinist?

A CNC operator generally runs and monitors machines but may not set them up or program them. A CNC machinist, on the other hand, is responsible for programming, setting up, and troubleshooting CNC machines.

3. Can I learn CNC programming online?

Yes, many platforms offer online courses for CNC programming. You can also find tutorials on YouTube and other educational websites to learn G-code and CAD/CAM software.

4. Is building my own CNC machine worth it?

Building your own CNC machine can be highly rewarding and educational. It provides hands-on experience and a deeper understanding of how CNC systems operate.

5. What tools are essential for CNC machining?

Essential tools include cutting tools, spindle motors, clamping devices, and measuring instruments like calipers and micrometers. Understanding different spindle options, such as those found at spindlemotorshop.com, is key to improving your machining capabilities.

Conclusion

Getting CNC experience involves a combination of education, hands-on training, and practice. Whether you choose to enroll in a trade school, secure an apprenticeship, learn on the job, or even build your own CNC machine, each path provides valuable experience and builds the foundation of skills needed to excel in this growing field. Remember, becoming a CNC machinist is not just about running machines; it’s about understanding how every component—from spindle motors to control systems—works together to produce precision parts.

Visit spindlemotorshop.com for a wide range of high-quality spindle motors and other essential components to kickstart or enhance your CNC journey. Your path to becoming a skilled CNC machinist starts today—take that first step, and watch your expertise grow.