How to Get Orders for CNC

In today’s competitive manufacturing landscape, securing CNC machining orders requires a strategic approach combined with technical expertise. Whether you’re running a small machine shop or expanding your CNC machining service, this comprehensive guide will help you attract and retain valuable customers.

Understanding the CNC Machining Market

The CNC machining industry continues to grow, driven by demand from aerospace, automotive, medical, and consumer products sectors. Success in this market requires understanding both the technical aspects of CNC machining and effective business development strategies. Having the right equipment, like a reliable 2.2KW ER20 Air-Cooled Spindle, is just the beginning.

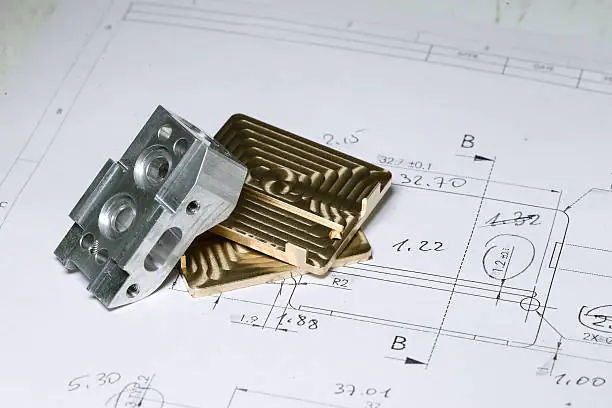

A professional-grade CNC spindle is essential for delivering quality machining services

Building Your Machine Shop’s Foundation

Essential Equipment

Your shop needs reliable machinery to handle various orders:

- CNC milling machines

- CNC lathes

- Quality measurement tools

- Advanced spindle systems

Material Capabilities

Demonstrate expertise in machining:

- Stainless steel

- Aluminum

- Plastics

- Exotic materials

Developing a Competitive Edge

To stand out in the CNC machining service market:

- Invest in high-quality equipment

- Maintain strict quality control

- Offer competitive pricing

- Provide excellent customer service

- Meet tight deadlines

The 1.5KW ER11 Square Air-Cooled Spindle with Flange enables precise machining for demanding projects

Marketing Your CNC Services

Online Presence

Create a professional website featuring:

- Portfolio of completed projects

- Equipment specifications

- Quality certifications

- Contact information

Digital Marketing

Implement these strategies:

- Search engine optimization (SEO)

- Social media marketing

- Email newsletters

- Industry forums participation

Targeting the Right Industries

Focus on industries that need regular CNC machining services:

- Medical device manufacturers

- Aerospace suppliers

- Automotive parts makers

- Industrial equipment manufacturers

Building Client Relationships

Strong relationships are crucial for recurring orders:

“The key to long-term success in CNC machining is not just technical excellence, but building trust with clients through consistent quality and communication.”

Quality Assurance and Certification

Maintain high standards through:

- ISO certification

- Quality management systems

- Regular equipment calibration

- Staff training

Upgrade to the 3.5KW ER20 Air-Cooled Spindles for handling larger production runs

Pricing Strategies

Develop competitive pricing by:

- Understanding market rates

- Calculating true costs

- Offering volume discounts

- Providing quick quote turnaround

Streamlining Order Process

Make it easy for clients to order:

- Online quote system

- Clear communication channels

- Simple ordering process

- Regular status updates

Networking and Industry Events

Participate in:

- Trade shows

- Industry conferences

- Local manufacturing groups

- Online forums

Managing Production Time

Optimize your operation for:

- Quick turnaround times

- Efficient production scheduling

- Regular maintenance windows

- Emergency capacity

Handling Custom Orders

Develop processes for:

- Prototype development

- Small batch production

- Custom material requests

- Special finishing requirements

Documentation and Communication

Maintain detailed records of:

| Document Type | Purpose | Update Frequency |

|---|---|---|

| Quality Reports | Verify specifications | Every order |

| Machine Logs | Track performance | Daily |

| Customer Requirements | Ensure accuracy | Per project |

| Material Certifications | Quality assurance | As needed |

Expanding Service Offerings

Consider adding:

- Design assistance

- Assembly services

- Finishing operations

- Inventory management

Continuous Improvement

Regularly:

- Update equipment

- Train staff

- Optimize processes

- Gather customer feedback

FAQs

1. What industries typically need CNC machining services?

Aerospace, automotive, medical device manufacturing, and industrial equipment makers are primary markets for CNC machining services. Each industry has specific requirements and quality standards.

2. How can I provide competitive quotes for CNC work?

Understand your operational costs, maintain efficient processes, and invest in quality equipment like precision spindles. Track material costs and optimize production time to offer competitive pricing while maintaining profitability.

3. What certifications do I need to attract more CNC orders?

ISO 9001 certification is essential. Industry-specific certifications like AS9100 for aerospace or ISO 13485 for medical devices can open additional markets.

4. How important is turnaround time for getting CNC orders?

Very important. Quick turnaround times can be a major competitive advantage. Efficient production planning and reliable equipment are crucial for meeting tight deadlines.

5. What should I include in my CNC machining service portfolio?

Include diverse examples of completed projects, highlighting complex parts, different materials, and various industries served. Document your quality processes and equipment capabilities.

Conclusion

Success in getting CNC orders requires a combination of technical excellence, business acumen, and strong customer relationships. By investing in quality equipment, maintaining high standards, and building a strong market presence, you can develop a steady flow of machining orders. Remember that each satisfied customer can become a source of recurring business and referrals.

Focus on continuous improvement in both technical capabilities and customer service. Stay updated with industry trends and maintain open communication with clients. With dedication to quality and customer satisfaction, your CNC machining business can thrive in this competitive market.

For more information about upgrading your machining capabilities or discussing specific equipment needs, don’t hesitate to contact us. Our team is ready to help you choose the right solutions for your growing business.