Introduction

CNC spindle motors are the heart of a CNC machine and are responsible for powering the cutting and drilling processes. Ensuring that these motors run efficiently and last longer can significantly impact the overall performance of CNC machines. This article will guide you through proven methods to enhance the runtime of CNC spindle motors, reducing wear and tear while maintaining high precision and output.

Understanding CNC Spindle Motors

The Role of Spindle Motors in CNC Machines

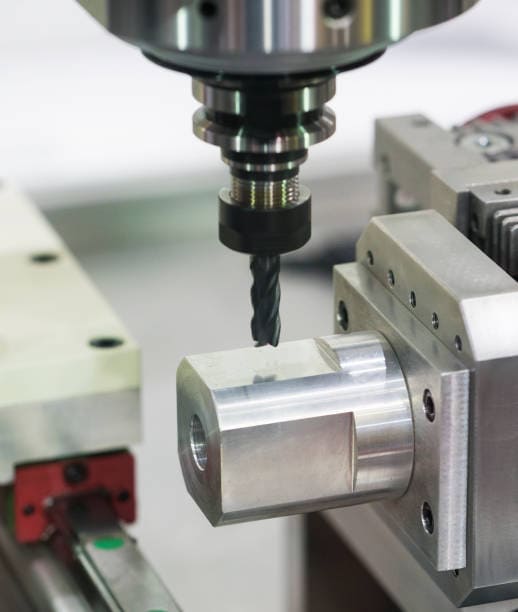

CNC spindle motors are responsible for rotating the cutting tool at high speeds, enabling precise shaping, cutting, and drilling. These motors are integral to the operation of CNC routers, lathes, and mills. The performance of the CNC spindle directly affects the accuracy and quality of the final product, making it essential to keep these motors running optimally for extended periods.

Factors Affecting Spindle Motor Performance

Several factors influence the performance and runtime of CNC spindle motors, including load conditions, operating speeds, and environmental conditions. For instance, overloading the motor or running it at excessive speeds for prolonged periods can lead to overheating and premature wear. Additionally, dust and debris generated during the machining process can interfere with motor components, reducing efficiency and increasing the risk of breakdowns.

Key Strategies for Enhancing Spindle Motor Runtime

Regular Maintenance and Care Tips

Regular maintenance is one of the most effective ways to extend the runtime of CNC spindle motors. This includes routine cleaning, lubrication, and checking for wear on bearings and seals. Keeping the motor free from dust and contaminants can prevent overheating and improve efficiency. Scheduling regular inspections will also help detect potential issues before they escalate into major problems, reducing downtime and repair costs.

Optimizing Spindle Motor Speeds for Different Materials

Each material requires a specific spindle speed to ensure optimal cutting and drilling. For example, harder materials like steel demand slower spindle speeds to prevent overheating and excessive wear, while softer materials like wood or plastic can be processed at higher speeds. Using the correct spindle speed for each material reduces strain on the CNC spindle motor, extending its operational life.

| Material | Recommended Spindle Speed (RPM) |

|---|---|

| Steel | 3,000 – 6,000 RPM |

| Aluminum | 8,000 – 12,000 RPM |

| Wood | 12,000 – 24,000 RPM |

Advanced Techniques to Extend Spindle Life

Implementing Efficient Cooling Systems

Efficient cooling is critical to extending the life of a CNC spindle motor. Spindle motors generate significant heat during operation, and without proper cooling, this heat can cause internal components to degrade over time. Air-cooled and water-cooled spindle motors are common solutions, with water-cooled systems being more effective for prolonged use in industrial settings. Implementing these systems can prevent overheating, reducing the risk of motor failure and downtime.

Upgrading to High-Performance Spindle Motors

Another way to improve spindle motor runtime is by upgrading to high-performance CNC spindle motors designed for durability and efficiency. These motors often feature better cooling systems, higher torque, and greater resistance to wear. Upgrading your spindle motor can provide a significant boost in performance, especially if you’re working with tough materials or running your machine for extended periods.

Troubleshooting Common Spindle Motor Issues

Identifying Symptoms of Spindle Motor Failure

Recognizing the early signs of spindle motor failure can save you from costly repairs and extended downtime. Common symptoms include unusual noises, vibrations, or a decrease in cutting performance. If you notice the spindle motor overheating or struggling to maintain consistent speeds, it’s time to inspect the motor for issues such as worn bearings or faulty wiring.

Quick Fixes vs. Professional Repairs

While some minor spindle motor issues can be resolved with quick fixes, such as cleaning or replacing worn parts, more serious problems may require professional repair. It’s essential to assess the severity of the issue before attempting any repairs. For example, replacing a worn-out bearing might be a simple fix, but if the spindle motor has internal damage, it’s best to consult a professional technician to avoid causing further harm.

Conclusion

Maximizing the spindle motor runtime of your CNC machine is critical for ensuring optimal performance, reducing downtime, and extending the life of the machine. Regular maintenance, proper cooling, and upgrading to high-performance motors are all key strategies for achieving this goal. By keeping your CNC spindle in top condition, you can significantly improve the efficiency and productivity of your operations.

- Maintain your CNC spindle motor through regular cleaning, lubrication, and inspections.

- Optimize spindle motor speeds based on the materials you’re working with to prevent wear and overheating.

- Invest in efficient cooling systems to keep spindle motors from overheating during extended use.

- Consider upgrading to high-performance spindle motors for better durability and efficiency.

- Troubleshoot early signs of spindle motor failure and seek professional repairs for complex issues.

FAQs

What is the average lifespan of a CNC spindle motor?

The lifespan of a CNC spindle motor can vary depending on the operating conditions, but with proper maintenance, most spindle motors can last between 5,000 and 10,000 hours of operation.

How often should spindle motors be serviced for optimal performance?

Spindle motors should be serviced at least once a year, or more frequently if they are used in demanding or continuous operations. Regular checks for lubrication, bearing wear, and cooling efficiency are essential to ensure long-term performance.

What maintenance routines improve spindle motor runtime?

Key maintenance routines include regular cleaning to remove dust and debris, proper lubrication of moving parts, and periodic inspection of bearings and seals for wear and tear. Keeping the spindle motor in good condition can significantly extend its runtime.

Can upgrading my spindle motor make a significant difference?

Yes, upgrading to a high-performance spindle motor can improve efficiency, reduce downtime, and allow for better handling of tough materials. High-performance motors often come with enhanced cooling systems and higher torque, making them ideal for heavy-duty operations.

How do temperature variations affect spindle motor performance?

Temperature fluctuations can affect the performance of CNC spindle motors. Excessive heat can cause components to expand, leading to misalignment and wear, while extremely cold conditions can make the motor more prone to brittleness and damage. Implementing efficient cooling systems helps maintain optimal operating temperatures.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.