How to Learn CNC Programming Online

Learning CNC programming can open up a world of opportunities, whether you are aiming to work in manufacturing, boost your skills for a new career, or simply satisfy a personal interest in Computer Numerical Control (CNC) technology. Thanks to the availability of numerous online resources, you can now acquire CNC programming skills right from your home. In this guide, we’ll cover everything you need to know to successfully learn CNC programming online, from understanding the basics to mastering advanced techniques.

What is CNC Programming?

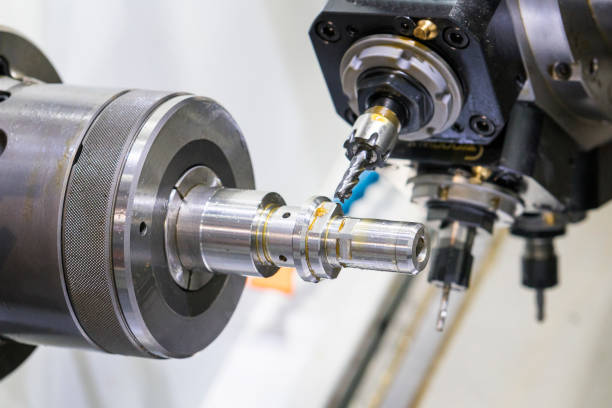

CNC programming is the process of creating a set of instructions for a CNC machine to follow, enabling it to carry out precise operations like cutting, drilling, and shaping materials such as metal, wood, and plastic. Essentially, it involves using G-code, a language that tells the machine how to move, how fast, and what actions to perform. CNC programming allows for high accuracy and repeatability, making it essential for many industries, including automotive, aerospace, and woodworking.

The programming process generally involves two main parts:

- CAD (Computer-Aided Design): Creating a digital model of the part to be produced.

- CAM (Computer-Aided Manufacturing): Generating the G-code that controls the CNC machine based on the CAD model.

Why Learn CNC Programming Online?

There are several compelling reasons to learn CNC programming online, including convenience, affordability, and access to a wide range of high-quality resources. Let’s take a closer look at these benefits:

- Flexibility: Online learning allows you to learn at your own pace, making it possible to fit study time into your busy schedule.

- Access to Expert Resources: Many online platforms feature courses taught by experienced professionals in the field, giving you access to industry-level knowledge.

- Affordability: Compared to in-person classes, online CNC programming courses are often more affordable, and many free resources are also available.

If you’re serious about learning CNC programming and want to kickstart your journey, you can start with fundamental topics like G-code and machine operations, before moving on to advanced CAD/CAM programming.

Best Online Resources to Learn CNC Programming

1. Online Courses

Enrolling in an online course is one of the best ways to systematically learn CNC programming. Here are some popular online platforms to consider:

- Udemy: Offers a variety of CNC programming courses, including beginner-friendly options and more advanced courses for those interested in 5-axis CNC.

- Coursera: Features courses taught by university instructors, which can provide a more academic approach to CNC programming.

- LinkedIn Learning: A great resource for short, targeted lessons on specific aspects of CNC programming.

These platforms allow you to learn about G-code generation, toolpath planning, and much more in a structured manner.

2. YouTube Tutorials

If you prefer visual learning, YouTube can be a great place to start. Many experts in CNC programming share comprehensive tutorials, covering everything from basic G-code commands to advanced machining techniques. The benefit of YouTube is that it’s free, but the downside is that you may need to piece together content from different channels to get a complete understanding.

3. CAD/CAM Software with Integrated Learning Tools

Learning how to use CAD/CAM software is an essential part of CNC programming. Some popular programs include:

- Fusion 360: Offers an integrated learning experience through tutorials and community support, making it easier to understand toolpath generation and simulation.

- SolidWorks: While not specifically CNC-focused, it’s great for creating models that you can then translate into G-code using CAM software.

- Mastercam: This is one of the most popular CAM software solutions in the industry. It also has an array of tutorials and user guides to help new users get accustomed.

You can find these programs’ tutorials on their respective websites or check out resources like SpindleMotorShop to understand how the CNC spindle works and get recommendations for compatible software.

4. CNC Simulation Software

Another excellent way to learn CNC programming is to practice with CNC simulation software. These programs allow you to test your G-code before running it on an actual machine, which is especially helpful for beginners. Simulation software helps you visualize what the machine will do based on the program, allowing you to identify and correct mistakes.

Popular CNC simulation software includes:

- CNC Simulator Pro: Ideal for beginners as it provides a real-time virtual environment to test your CNC programs.

- NC Viewer: A web-based G-code viewer that lets you simulate tool paths without needing to install any software.

By combining CNC simulation tools with online courses, you can get hands-on practice without the need for expensive equipment.

Step-by-Step Guide to Learning CNC Programming Online

1. Start with G-Code Basics

The first step to learning CNC programming is to understand G-code, the language of CNC machines. G-code consists of a set of commands, such as:

- G00: Rapid movement to a specified position.

- G01: Linear movement to a position at a specified feed rate.

- G02 and G03: Circular interpolation commands for clockwise and counterclockwise movements.

Understanding these basic commands is essential to control the linear and rotational movements of CNC machines.

2. Learn About Machine Setup and Tooling

Setting up a CNC machine involves several key steps, including installing the right tools, defining zero points, and ensuring all settings are correctly configured.

- Spindle Selection: Selecting the right spindle is essential for achieving the desired quality and efficiency. For example, a 1.5KW ER11 Square Air-Cooled Spindle with Flange can be ideal for beginners who are just starting to learn about CNC spindle motors.

3. Understand Toolpath Generation

After understanding the basics of G-code, the next step is learning how to generate toolpaths. This involves using CAM software to translate CAD models into commands that your CNC machine can understand.

A toolpath defines the path the cutting tool will follow, and it’s vital to get this right for efficiency and precision. You can practice toolpath generation using software like Fusion 360 or Mastercam.

4. Test with CNC Simulation Software

Before running your CNC machine, it’s crucial to simulate the operation to avoid mistakes that could damage the machine or ruin your workpiece. Using simulation tools like CNC Simulator Pro can help you see how the machine will execute your program, allowing you to make any necessary corrections beforehand.

5. Practice, Practice, Practice

The most important step is to practice. Begin with simple parts, and gradually increase the complexity as your understanding grows. You can download or create your own CAD models to practice toolpath generation and G-code programming. Some websites also offer practice projects, giving you a way to test your skills in a structured manner.

Choosing the Right CNC Programming Path

Hobbyist vs. Professional Path

Hobbyist Learning Path: If you are a hobbyist, focus on learning basic G-code, machine setup, and toolpath creation. Start with affordable equipment like a hobbyist CNC router, and use free resources such as YouTube tutorials and forums to guide you.

Professional Learning Path: If you’re aiming for a career in CNC machining, consider investing in a structured course and obtaining certifications. Learn advanced topics such as 5-axis programming, multi-tool operations, and machine calibration. It’s also essential to learn how to operate various spindles, such as the 3.5KW ER25 Air-Cooled Spindle for more advanced applications.

Overcoming Common Challenges in Learning CNC Programming

1. Understanding Complex G-Code Commands

Initially, G-code can seem complicated. One effective way to overcome this is by breaking the code into smaller, more manageable parts and practicing each command individually. CNC simulation software also helps by showing you the effects of each command in real time.

2. Dealing with Mistakes

Mistakes are common when you’re learning CNC programming. Always simulate your program before running it on a real machine to avoid costly errors. Forums like CNCZone and Practical Machinist can also be invaluable resources for troubleshooting common issues.

3. Staying Updated

Technology in the CNC field is constantly evolving, so staying updated is crucial. Follow CNC technology blogs, forums, and subscribe to newsletters from websites like SpindleMotorShop to stay informed about the latest spindle motors and CNC innovations.

Frequently Asked Questions (FAQs)

1. How long does it take to learn CNC programming?

Learning the basics of CNC programming can take anywhere from a few weeks to a few months, depending on your pace and the complexity of the topics covered. To become proficient, expect to dedicate several months of focused learning and practice.

2. Do I need a CNC machine to learn CNC programming?

No, you don’t need a physical CNC machine to start learning. You can practice G-code and toolpath generation using CNC simulation software, which allows you to visualize the machining process without the risk of damaging any equipment.

3. What software should I use to learn CNC programming?

Some popular software for learning CNC programming includes Fusion 360, Mastercam, and CNC Simulator Pro. These tools provide both design and simulation capabilities, making them suitable for beginners.

4. What is G-code, and why is it important?

G-code is the programming language used to control CNC machines. It tells the machine where to move, how fast, and when to perform specific actions, making it essential for precise machining.

5. Can I learn CNC programming on my own?

Yes, many people learn CNC programming on their own using online resources, including courses, YouTube tutorials, forums, and CNC simulation software.

Conclusion

Learning CNC programming online is not only feasible but also convenient, thanks to the wealth of resources available today. From structured courses on platforms like Udemy and LinkedIn Learning, to free YouTube tutorials and simulation tools, there are numerous ways to acquire CNC programming skills at your own pace. By starting with the basics, using quality learning resources, and practicing regularly, you’ll be well on your way to becoming proficient in CNC programming.

Remember, it’s important to start with the fundamentals, such as G-code, machine setup, and toolpath creation. The journey may have its challenges, but with persistence and the right tools, you can master CNC programming. If you’re looking for reliable equipment like spindles or other CNC components, check out SpindleMotorShop for a wide variety of parts that will help you get started on your CNC journey.