How to Make Money with CNC

In today’s world, technology continues to evolve and offer new opportunities for individuals and businesses alike. CNC (Computer Numerical Control) machines, which use software to control tools like routers and mills, are an excellent example of a technological advancement that can open doors to various ways of making money. With CNC machines, it is possible to produce high-quality, intricate designs with incredible precision. This article will guide you through the possibilities of making money with CNC, covering various aspects such as projects, CNC woodworking, metalworking, and tips on creating a successful CNC business.

Understanding the Basics of CNC Machines

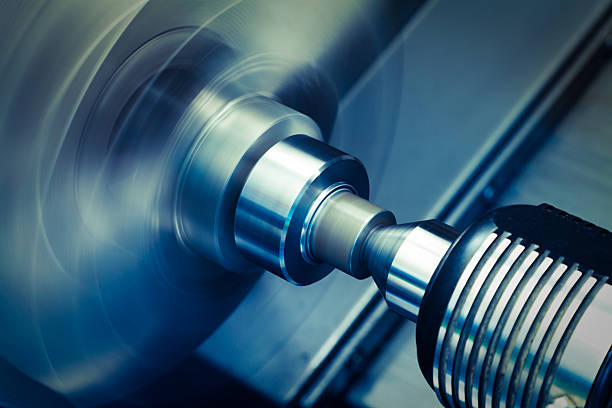

CNC machines have gained immense popularity because they combine technology and traditional craftsmanship in unique and profitable ways. CNC stands for Computer Numerical Control, and these machines are used to cut, carve, engrave, or mill materials using a computer and specific programming. The CNC machine receives instructions from the program, allowing you to create designs that are far more precise compared to traditional hand tools. CNC machines come in various types, such as CNC routers, mills, and lathes.

The core of the CNC business revolves around creativity and high-quality production. The versatility of these machines allows for a range of projects, from woodworking and metalworking to cutting acrylics and plastics. CNC machines can be used for both professional and artistic purposes, allowing entrepreneurs to generate income from customized products.

To start your CNC business, it is crucial to understand the different kinds of CNC machines available and select one that suits your goals. CNC routers are popular choices for woodworking and light metalworking projects, while CNC mills can be used for more heavy-duty applications. Regardless of which CNC machine you choose, investing in a quality spindle is vital. For instance, this 2.2KW ER16 Air-Cooled Spindle can be an excellent choice for various applications.

Profitable CNC Projects: Turning Ideas into Income

One of the best ways to make money with a CNC machine is by undertaking profitable projects that cater to specific markets. Depending on your interests and the types of CNC machines you have, there are several potential projects you could explore:

- Wooden signs and wall art: Personalized wall art is always in demand, whether for home decor or office spaces. You can use CNC routers to create customized signs with names, quotes, or even detailed carvings. Offering bespoke signs can set your CNC business apart and attract customers who want a unique touch to their decor.

- Furniture and Home Decor: CNC machines can create exquisite pieces of furniture. From creating custom tabletops to making fine details in chairs, tables, or other home decor items, CNC woodworking offers countless possibilities.

- Gifts and Souvenirs: CNC routers are ideal for creating personalized gifts like wooden clocks, engraved jewelry boxes, or custom keychains. Focusing on the gift market can bring in steady revenue as people are always looking for unique and meaningful gifts for special occasions.

- CNC Metalworking Projects: CNC mills and routers can also be used for metalworking projects, such as customized metal parts for machinery, personalized metal wall art, or custom brackets and hardware.

By diversifying the kinds of projects you offer, you can cater to different markets and increase your earning potential. Consider promoting your offerings through platforms like Etsy or your website to reach a wider audience.

Developing a CNC Business Plan

Having a well-thought-out business plan is crucial for any CNC venture. A business plan serves as your guide to success and provides you with a roadmap to follow while managing your CNC business.

Steps to Create a Successful CNC Business Plan

- Identify Your Niche: Decide what specific products or services you want to offer. Do you want to specialize in CNC woodworking or metalworking? Your niche will determine your target audience, marketing strategies, and production methods.

- Invest in the Right Tools: Make sure you have the right tools for the job. For a CNC business, the spindle motor is an important part of the setup. For example, this 3.5KW ER25 Air-Cooled Spindle is a reliable option for high-quality production.

- Budget and Funding: Calculate how much capital you need to start your business. Consider the cost of the CNC machine, spindle motors, raw materials, software, and other accessories. A solid budget will prevent any financial pitfalls as you grow.

- Marketing and Promotion: Marketing is key to attracting customers to your CNC business. Leverage social media, websites, and word of mouth to create awareness. Set up a dedicated website with clear photos of your products and provide easy ways for people to contact you.

- Customer Service: Providing excellent customer service can set you apart from competitors. Offering a customization option for products can increase customer satisfaction and encourage repeat business.

CNC Woodworking: Carving a Niche in the Market

Woodworking is one of the most popular uses of CNC machines. Many people enter the CNC business with a focus on woodworking due to its wide variety of applications and relatively lower barrier to entry. With a CNC router, it is possible to cut, engrave, carve, and mill woodworking projects of different scales and complexities.

Popular CNC Woodworking Projects

- Custom Cabinets: CNC woodworking is great for creating cabinets with precise designs, ensuring accuracy and consistency throughout. Custom cabinets are popular among homeowners and commercial spaces.

- Wooden Toys: Using a CNC machine, you can create wooden toys that are safe and customizable. With people looking for eco-friendly alternatives to plastic toys, the demand for well-crafted wooden toys is growing.

- Signs and Logos: Many businesses require custom wooden signs or logos for their branding. CNC routers make it easy to create high-quality signs that convey a professional image.

When starting out in CNC woodworking, it is essential to invest in a reliable spindle. An excellent option for woodworking is the 1.5KW ER11 Round Air-Cooled Spindle, known for its durability and versatility.

Making Money with CNC Router Projects

A CNC router can be used to create several high-value products that are in demand. Here are some ways to make money with a CNC router:

- Custom Engravings: CNC routers excel at engraving wood, acrylic, and plastics. By offering custom engravings, such as personalized plaques or trophies, you can cater to clients like schools, organizations, and corporations.

- Cutting Boards and Kitchen Accessories: Handmade kitchen items are popular among customers who appreciate craftsmanship. Using a CNC router, you can produce high-quality cutting boards, utensil holders, or serving trays that are both functional and beautiful.

- Architectural Details: CNC routers can be used to create intricate architectural elements such as crown moldings, corbels, and brackets. These items can be sold to home builders and contractors for use in custom homes and restoration projects.

To get the best results in router projects, using a good-quality spindle like the 800W ER11 Air-Cooled Spindle is recommended.

Scaling Your CNC Business with Metalworking

Apart from woodworking, metalworking is another way to make money with CNC machines. Metalworking CNC projects require more specialized machines and tools, but they can be highly profitable. Metalworking projects could include:

- Custom Car Parts: Enthusiasts often require custom metal parts for cars and motorcycles. CNC machines can produce these with high precision.

- Decorative Metal Items: CNC machines can cut or engrave intricate metal items, like decorative panels for home decor or garden sculptures.

- Mechanical Components: Many small manufacturers need metal components for their products, and they often look for local suppliers who can produce high-quality parts at a reasonable price.

The key to scaling a metalworking business is to offer quality products consistently. Investing in a powerful spindle motor, such as the 6KW ER32 Air-Cooled Spindle, can help you achieve this goal.

CNC Tooling and Maintenance

Proper tooling and maintenance are essential for the longevity and efficiency of your CNC machine. Here are some tips to ensure that your machine performs well:

- Tool Selection: Make sure you select the right tools for each project. The choice of tools depends on the type of material you’re working with, the design, and the required finish.

- Regular Cleaning: Clean your CNC machine and spindle regularly to ensure it operates smoothly. Dust and debris can interfere with the machine’s accuracy and potentially cause damage.

- Lubrication: Keep all the moving parts well-lubricated. Proper lubrication will reduce wear and tear and prolong the life of the machine.

Maintenance ensures not only the quality of the products but also the safety of the operation. Neglecting maintenance can lead to machine breakdowns and production delays, affecting your income.

FAQs

1. How much can you earn with a CNC machine?

The earnings depend on the products you create, the scale of production, and your market reach. On average, a small CNC business can make anywhere from $500 to $10,000 per month based on demand.

2. What kind of CNC machine is best for beginners?

A CNC router is often best for beginners due to its versatility and ease of use. You can start with smaller projects like engravings and progress to larger pieces.

3. What materials can be used in CNC projects?

CNC machines can work with a variety of materials, including wood, metal, plastic, and acrylic. The type of machine and tools you use will determine the materials you can work with.

4. Do I need a business license to start a CNC business?

It depends on your location. Typically, you will need a business license to operate commercially. You should check local regulations to ensure compliance.

5. How do I promote my CNC products?

You can promote your CNC products online through platforms like Etsy, Amazon, or your own website. Additionally, social media and local advertising can help attract customers.

Conclusion

Making money with CNC machines is a fantastic opportunity for individuals who are creative, hands-on, and business-minded. By exploring different niches like woodworking, metalworking, and custom projects, you can turn your passion into profit. Whether you are creating personalized home decor, intricate metal parts, or custom cabinetry, the CNC machine offers limitless potential.

The key to success lies in selecting the right tools, such as investing in a good spindle, and focusing on marketing and customer satisfaction. Once you find your niche and build a strong business plan, your CNC business can grow into a profitable and rewarding venture.

Feel free to explore different possibilities and start your journey with CNC today. For those interested in quality spindle motors, check out SpindleMotorShop for a wide variety of spindles suitable for all types of CNC machines.