Introduction

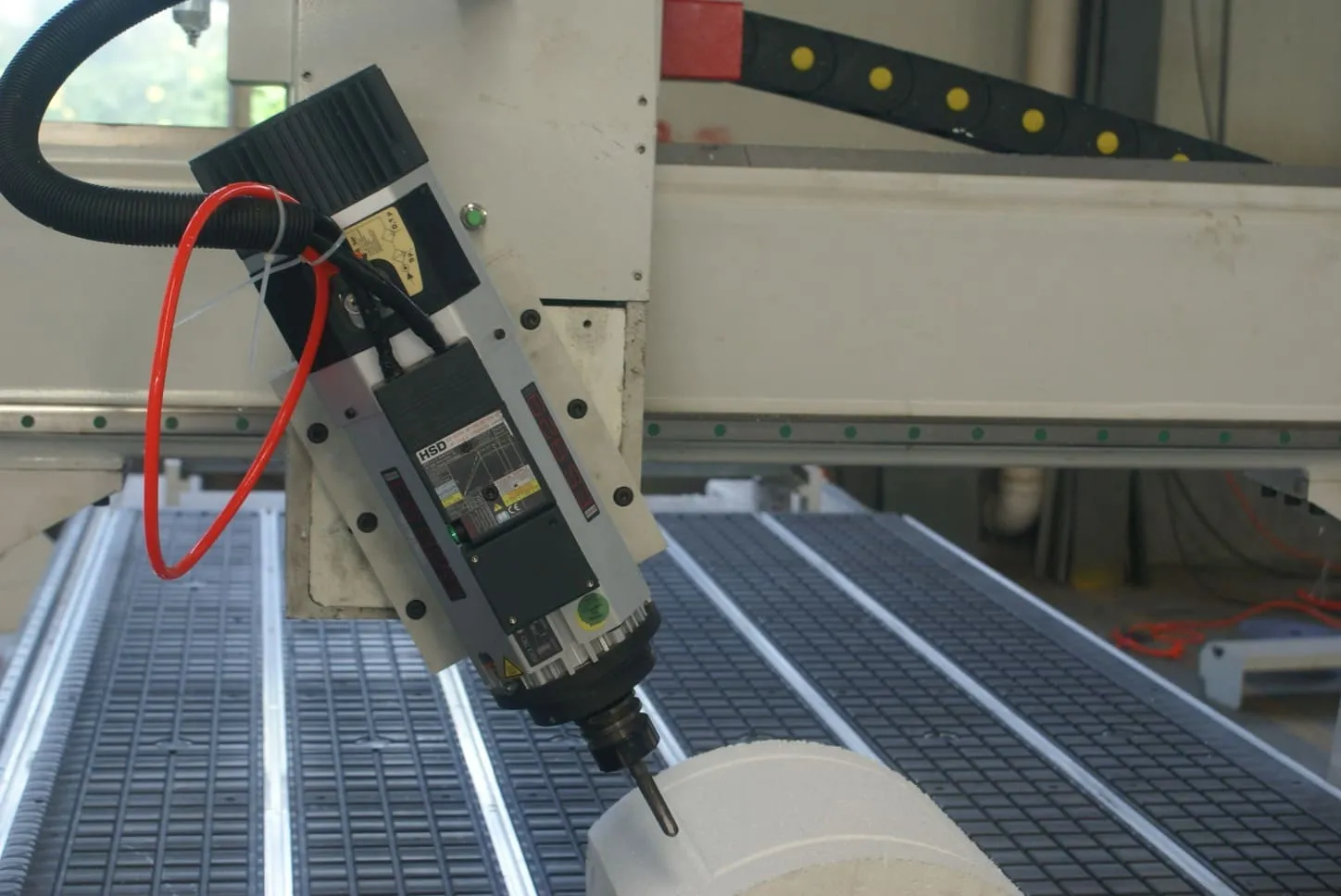

During the installation of the electro spindle, correct wiring is essential to ensure its normal operation and safe use. The spindles of different models and manufacturers may have different wiring requirements, so before wiring, be sure to read and follow the wiring instructions and manuals provided by the manufacturer. In order to avoid dangers such as short circuits, abnormal voltage/current or electric shock, it is recommended to consult a professional before operation. This article will introduce the general steps of electro spindle wiring to help you complete the wiring work correctly.

Confirm the specifications of the electric spindle

Voltage

First, confirm the rated voltage of the electric spindle, such as 380V three-phase electricity or 220V single-phase electricity. This is crucial for selecting a suitable inverter.

Power

Confirm the power of the electric spindle so that you can choose a suitable inverter. The power of the inverter should match the electric spindle to ensure its normal operation.

Speed

Understand the rated speed of the electric spindle so that you can set the corresponding frequency and other parameters on the inverter. The correct setting can ensure that the electric spindle operates within the expected working range.

Connection from the inverter to the electro spindle

CNC spindle cable connection

Connect the output terminal of the inverter (usually marked with “U”, “V”, “W”) to the input terminal of the electric spindle. Make sure that the cable specifications and wiring methods meet the requirements of the electric spindle, and the cross-sectional area of the cable should be able to withstand the current load.

Spindle cable connection

Power line connection: Make sure that the power line of the spindle is correctly connected to the output terminal of the inverter. Generally speaking, the spindle terminals are marked with “U”, “V”, “W”. Make sure the connection is tight to avoid looseness.

Grounding line connection: Connect the grounding line of the spindle to the grounding terminal on the spindle. Make sure that the grounding line has good contact to avoid electrical interference and safety hazards.

Wiring check

Check all connections

Check whether the power input and output terminals of the inverter and the wiring of the spindle are correct. Make sure all connection points are tight to avoid looseness.

Confirm grounding

Make sure that both the inverter and the spindle are properly grounded, and check whether the grounding line is disconnected or has poor contact.

Startup Test

Start the inverter

Start the inverter and observe the operating status of the spindle. Check whether the speed, noise and vibration of the spindle are normal.

Gradually increase the load

Gradually increase the load and observe the operation of the spindle under different loads. Check whether the operation is stable and ensure that the spindle performs well under various working conditions.

Safety Precautions

1. Before doing any wiring work, make sure the power is completely turned off.

2. If you are not familiar with electrical wiring, please seek help from a professional electrical engineer to ensure safety and accuracy.

Conclusion

Correct electric spindle wiring is essential for its normal operation and safety. From confirming the specifications of the electric spindle, connecting the inverter to the spindle, and checking the wiring to the startup test, every step needs to be carefully operated. Be sure to follow the manufacturer’s guidance and safety regulations, and seek professional help when necessary to ensure the stability and safety of the electric spindle system.

Summary FAQ Based on the Article

Q1: What specifications need to be confirmed before wiring the electric spindle?

A1: The rated voltage, power and speed of the electric spindle need to be confirmed in order to select the appropriate inverter and set the corresponding parameters.

Q2: How to connect the electric spindle to the inverter?

A2: Connect the output terminal of the inverter (marked with “U,” “V,” and “W”) to the input terminal of the electric spindle. Make sure that the cable specifications meet the requirements and that the connection is firm.

Q3: How to check whether the wiring of the electric spindle is correct?

A3: Check whether the power input and output terminals of the inverter and the wiring of the spindle are correct, ensure that all connection points are tightened and confirm that the grounding is good.

Q4: What should be paid attention to when starting the electric spindle?

A4: After starting the inverter, observe the operating status of the spindle, including speed, noise and vibration. Gradually increase the load and check the operating stability of the spindle under different loads.

Q5: What are the safety precautions in wiring work?

A5: Before wiring work, make sure that the power is completely turned off. If you are not familiar with electrical wiring, please seek help from a professional electrical engineer.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.