CNC machines have revolutionized manufacturing by providing precision, versatility, and efficiency in producing parts and components. Whether you are a novice just stepping into the world of CNC machining or an experienced machinist looking to refine your skills, working effectively with a CNC machine can elevate your projects to new heights. In this guide, we will delve into the core elements of CNC machining, from the tools needed to the best practices for achieving quality results. Let’s explore how to work with a CNC machine!

Understanding the Basics of CNC Machines

What is a CNC Machine?

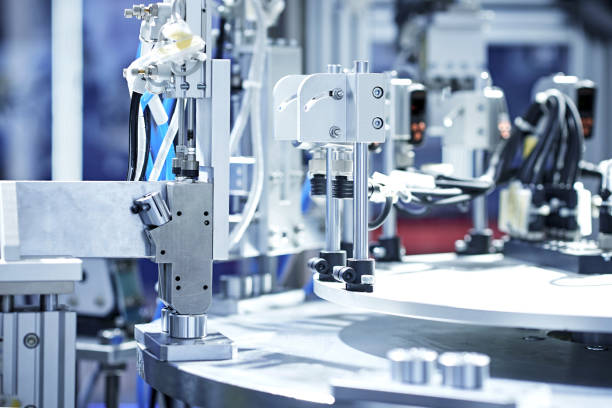

A CNC (Computer Numerical Control) machine is a piece of equipment that uses programmed software to control the movement of tools and machinery. It automates tasks like cutting, milling, drilling, and turning, ensuring precision, repeatability, and quality across multiple parts.

CNC machines use programming languages such as G-code to direct their actions. The operator designs the parts using CAD software and then converts those designs into machine-readable instructions. The CNC router or milling machine reads these instructions and moves accordingly.

The spindle is the heart of the CNC machine, responsible for holding and driving the cutting tool. For consistent performance, using a reliable spindle, such as the 24000RPM 0.8KW ER11 Water-Cooled Spindle, is crucial.

Components of a CNC Machine

CNC machines are made up of several components, each with a critical role in the machining process:

- Control Unit: Processes instructions from the G-code and tells the machine what to do.

- Spindle: Holds the cutting tool and rotates at various speeds, depending on the material and desired finish.

- Tooling: Includes cutting tools like end mills and drill bits used to shape the material.

- Work Table: Holds the material that is being machined.

- Axes: CNC machines usually have multiple axes, such as X, Y, and Z, which allow for different movement paths.

Types of CNC Machines

Different CNC machines cater to different kinds of work:

- CNC Routers: Best for wood, plastics, and soft metals. They are ideal for large and lightweight materials.

- CNC Mills: Can handle harder metals and produce intricate shapes. Equipped with powerful spindles, like the 2.2KW ER20 Air-Cooled Spindle, which ensures efficient cutting.

- CNC Lathes: Used for turning operations, suitable for creating cylindrical shapes.

Choosing the Right Tool for Your CNC Project

The selection of the right tool is crucial for the success of your CNC project. The tools determine the quality, precision, and time required to complete a part.

Types of Cutting Tools

- End Mills: The most common tool used in CNC machining for cutting in the X, Y, and Z axes. End mills come in different sizes and geometries, each suited for different materials and cuts.

- Ball Nose End Mills: These tools are ideal for 3D profiling and achieving smooth curves.

- Drills: For creating holes in the material, drills are used to precisely pierce through the workpiece.

Tip: When working on a project involving high-speed cuts in hard metals, consider using the 7.5KW ER32 Air-Cooled Spindle to maintain consistent power and precision.

Tool Selection Based on Material

The type of material determines the best tool for the job:

- Wood and Plastics: Single flute or two-flute end mills work well for materials like wood and plastic because they remove chips efficiently.

- Metals (e.g., Aluminum, Steel): Four-flute end mills are more suitable for metals, as they can provide the strength needed to cut harder materials.

Tool Holding and Spindle Compatibility

Make sure your tools are compatible with your spindle type. For example, an ER20 collet is compatible with the 24000RPM 3.2KW ER20 Water-Cooled Spindle, ensuring the tool stays stable during high-speed operations.

Programming Your CNC Machine

Using CAD/CAM Software

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software are used to create models and generate the tool paths required for CNC machining. The software converts your design into G-code, which the CNC machine uses to make cuts.

Popular CAD/CAM software options include:

- Fusion 360: User-friendly and great for beginners.

- Mastercam: Offers advanced functionalities for more complex projects.

- SolidWorks: Preferred for its powerful CAD modeling capabilities.

Writing and Editing G-Code

The language of CNC machines, G-code, tells the machine exactly how to move. It may seem complicated at first, but understanding G-code allows you to make manual adjustments that CAD/CAM software might not handle optimally.

Here are some common G-code commands you should know:

- G00: Rapid movement without cutting.

- G01: Linear cutting movement.

- M03/M05: Start/stop the spindle.

Example of G-Code for CNC Milling

Tip: Make sure to always simulate your G-code in your CAM software before running it on the machine. This helps avoid costly mistakes.

Setting Up the CNC Machine for Machining

Proper Workpiece Setup

The workpiece needs to be properly aligned and secured before machining begins to ensure accurate cuts. Here are steps to set up the workpiece:

- Material Clamping: Use clamps or a vacuum table to secure the workpiece.

- Setting Zero: Use the spindle to establish a zero point or work offset (e.g., G54), which serves as the starting point for the tool.

- Tool Length Compensation: Set the tool length to adjust for different cutting tools, ensuring precision in cutting depth.

Checking the Spindle

Always ensure that the spindle is aligned and running smoothly before machining. The spindle’s performance can greatly affect the quality of the cut. For example, a 5.5KW ER32 4-Pole Air-Cooled Spindle is ideal for high-precision tasks due to its stability and power.

Dry Run Testing

Before starting actual machining, always run a dry test (with no material or minimal depth). This helps ensure that the tool paths and machine settings are correct, preventing any potential collisions or errors.

Machining Process: From Start to Finish

Step-by-Step Machining

- Load the Program: Upload the G-code generated by your CAM software.

- Run a Dry Test: Check for errors in the G-code or unexpected movements.

- Start the Spindle: Set the spindle speed according to the material being machined.

- Engage the Tool: Slowly move the tool to the workpiece, watching for correct engagement.

- Machining: Once confident in the setup, begin the full operation.

- Inspection: Stop periodically to inspect the part to ensure dimensions are within tolerance.

Monitoring Machining Time

Efficiency is key in CNC machining. Monitor machining time to identify areas for improvement, such as tool wear or excessive repositioning. A reliable, high-performance spindle can significantly reduce machining time while maintaining quality.

Ensuring Quality Finish in CNC Machining

Achieving a Smooth Surface Finish

To achieve a high-quality surface finish:

- Use a Smaller Stepover: A smaller stepover reduces the ridges left between tool paths, resulting in a smoother surface.

- Reduce Spindle Speed: For final passes, lowering the spindle speed can minimize tool marks and improve finish.

- Finishing Tools: Use finishing tools with fewer flutes, as they tend to leave a better finish on the material.

Tool Wear and Replacement

Tool wear is an inevitable part of CNC machining. Monitor tools for signs of wear, such as reduced cutting efficiency or visible burrs on the finished parts. Replace worn tools promptly to ensure consistent quality and avoid compromising your projects.

Quality Checks

Use measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM) to ensure that the final part meets the required dimensions and tolerances. Implementing regular quality checks throughout the machining process helps to detect issues early, reducing waste and rework.

Safety Precautions When Working with CNC Machines

Proper Safety Gear

Working with CNC machines involves certain risks, especially when dealing with high speeds and sharp tools. Always wear the appropriate safety gear, including:

- Safety Glasses: Protect your eyes from flying chips and debris.

- Gloves: Use gloves when handling raw materials, but remove them when working directly with moving parts to prevent entanglement.

- Hearing Protection: CNC machines can be loud, especially during high-speed operations. Use earplugs or earmuffs to protect your hearing.

Machine Maintenance for Safety

Regular maintenance of the CNC machine is crucial to prevent malfunctions that could lead to accidents. Here are some maintenance tips:

- Lubricate Moving Parts: Regularly lubricate the machine’s moving components to prevent wear and overheating.

- Check for Loose Bolts: Loose bolts can lead to vibrations, affecting precision and safety. Tighten them as part of regular checks.

- Inspect Safety Features: Make sure that safety features like emergency stop buttons and protective guards are functional.

Avoiding Common Hazards

- Never Leave the Machine Unattended: Always stay nearby while the CNC machine is running. This ensures you can react quickly if something goes wrong.

- Keep the Work Area Clean: A clean workspace reduces the risk of tripping and ensures that tools and materials are easily accessible.

- Avoid Wearing Loose Clothing: Loose clothing can get caught in the machine. Wear fitted attire to minimize this risk.

Common Issues and Troubleshooting Tips in CNC Machining

Tool Breakage

Tool breakage can happen for various reasons, such as incorrect feed rates or improper tool selection. Here are some tips to avoid this issue:

- Check Feed and Speed: Ensure that the feed rate and spindle speed are appropriate for the tool and material.

- Use the Right Tool: Select tools that are suitable for the hardness and type of material being machined.

- Inspect Tool Wear: Worn tools are more likely to break. Replace tools before they reach the end of their lifespan.

Poor Surface Finish

If the surface finish is rough or inconsistent, you might need to adjust some settings:

- Decrease Stepover: A smaller stepover can help improve surface finish.

- Check Tool Sharpness: Dull tools can leave unwanted marks. Replace dull tools promptly.

- Adjust Spindle Speed: Sometimes increasing or decreasing the spindle speed can help achieve a better finish.

Machine Vibration

Excessive machine vibration can negatively impact accuracy and surface finish:

- Tighten Bolts and Fixtures: Ensure that all parts of the machine are securely fastened.

- Use a Sturdier Spindle: A high-quality spindle, such as the 7.5KW ER32 Air-Cooled Spindle, can help minimize vibrations and maintain stability.

- Adjust Cutting Parameters: Reducing the depth of cut or feed rate can sometimes alleviate vibration issues.

FAQs

1. What is the most important factor in achieving a smooth CNC finish?

The most important factors are using a smaller stepover, maintaining tool sharpness, and optimizing spindle speed. All these elements contribute to a finer surface finish.

2. How do I choose the right spindle for my CNC machine?

The spindle choice depends on the material and type of work. For instance, the 2.2KW ER20 Air-Cooled Spindle is suitable for lighter operations, while heavier tasks require more powerful spindles.

3. Why is a dry run important in CNC machining?

A dry run is essential to verify that the tool paths are correct and to avoid collisions. It helps you identify potential issues in the program without damaging the workpiece or machine.

4. How can I reduce tool wear in CNC machining?

To reduce tool wear, make sure you are using the correct feed rate, spindle speed, and type of tool for the material. Also, replace tools before they become too worn to avoid compromising the quality of your cuts.

5. What are some good practices for CNC machine maintenance?

Regularly lubricate moving parts, inspect and tighten bolts, and check all safety features such as emergency stop buttons. Preventive maintenance helps to avoid unexpected breakdowns and ensures consistent performance.

Conclusion

Working with a CNC machine can be incredibly rewarding, allowing you to create precise and intricate components with ease. To be successful, you need a good understanding of the machine’s components, the right tools for your project, and a solid grasp of G-code and CAD/CAM software. By following best practices for setup, safety, and quality assurance, you can ensure your CNC projects are both efficient and high-quality.

Don’t forget that the choice of spindle plays a critical role in achieving the desired results. Explore options like the 24000RPM 0.8KW ER11 Water-Cooled Spindle or the 7.5KW ER32 Air-Cooled Spindle to find the right fit for your needs. With the right setup, tools, and knowledge, your CNC machining projects will reach new heights of precision and quality.

If you have any questions or need help selecting the right equipment, feel free to contact us. We’re here to help you make the most of your CNC machining journey.