Creating a CNC program for milling involves a combination of precision, creativity, and technical knowledge. CNC milling allows for the automated machining of intricate parts with high accuracy, transforming raw materials into detailed products. If you’ve been wondering how to write a CNC program for milling, this guide will take you through the essential steps, tools, and best practices involved. We’ll cover everything from understanding the basics to writing G-code, defining tool changes, and applying work offsets.

Introduction to CNC Milling

What is CNC Milling?

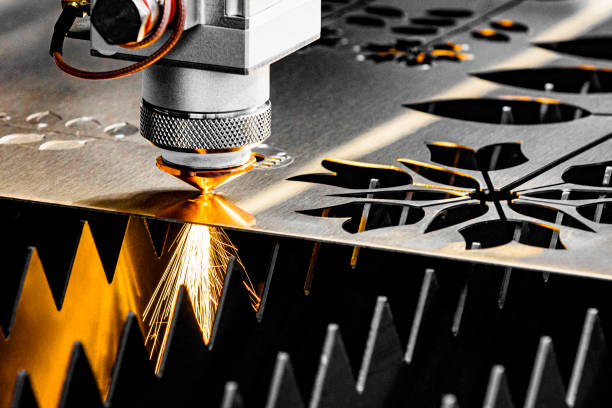

CNC milling is a subtractive manufacturing process that uses rotating cutting tools to remove material from a workpiece. The movements of the tool are controlled by a pre-programmed set of instructions, called a CNC program. These instructions are often written in G-code, a standard language for controlling CNC machines.

CNC milling is commonly used in industries such as automotive, aerospace, and toolmaking to manufacture complex parts with precision. By creating a program, you can tell the CNC machine exactly how to move, where to cut, and when to perform various operations.

Why Learn to Write a CNC Milling Program?

Writing your own CNC milling program has numerous benefits:

- Precision Control: Direct control over the cutting tool for intricate designs.

- Customization: Create a CNC program specifically suited to your project requirements.

- Efficiency: Optimize tool paths, workpiece handling, and production time.

Key Components of a CNC Milling Program

1. G-Code: The Language of CNC Programming

The foundation of a CNC program is G-code, which controls movements like cutting, drilling, and changing tools. Some common G-codes used in milling include:

- G00: Rapid movement

- G01: Linear feed movement

- G02/G03: Circular interpolation (clockwise/counterclockwise)

- G17/G18/G19: Plane selection

G-code is complemented by M-codes, which handle functions such as starting and stopping the spindle, coolant control, and program ends.

2. Work Coordinate Systems and Offsets

Work Coordinate Systems (WCS) help determine the reference points for machining. The G54-G59 codes are commonly used to set these offsets, allowing you to position the workpiece correctly on the milling machine.

Offsets are vital to ensure the tool length and workpiece position are accurately set, making sure each part is consistently machined to the desired specifications.

3. Tool Changes and Tool Length Compensation

In a milling operation, multiple tools are often used. M06 is the standard code for a tool change. After changing tools, you need to compensate for the new tool length using G43 or G44. Tool length compensation is essential to adjust for different tool lengths and ensure that each tool reaches the correct depth for cutting.

The 24000RPM 3KW ER20 Water-Cooling Spindle is an example of a spindle that offers the reliability and power needed for efficient CNC milling.

Steps to Write a CNC Milling Program

1. Define the Machining Cycle and Objectives

Before you write the CNC program, you need to define the machining objectives. This includes specifying:

- Workpiece Material: Understanding the material will help determine the optimal cutting speed and feed rate.

- Tool Requirements: Determine the tools required, such as end mills, drills, or face mills.

- Cycle Type: Identify the type of operations—whether facing, slotting, or contouring.

2. Setting the Workpiece Coordinates

To begin programming, you need to establish a reference point for your workpiece, usually defined as G54. This sets the initial coordinates where the CNC milling machine will start its operations.

- G54-G59: Define different work offsets if multiple parts are being machined on the same table.

- Zero Point: Usually, the lower-left corner or the center of the part is set as the zero point for X, Y, and Z coordinates.

3. Write the Initial Setup Code

The initial setup code prepares the machine for milling, including:

- G17: Selects the XY plane.

- G21: Specifies metric units (G20 for inches).

- G90: Sets absolute positioning mode.

- M06: Tool change command.

- G43 H01: Tool length compensation for tool number 1.

Example of Initial Setup Code:

This code sets the units to millimeters, selects the XY plane, loads tool number 1, compensates for tool length, and starts the spindle at 1500 RPM.

4. Program the Tool Paths

To create tool paths, use G-codes like G01 for linear cuts or G02/G03 for arcs. The feed rate is defined by F, which is important for controlling the cutting speed.

- Linear Move Example:

G02 X70.0 Y50.0 I10.0 J0.0

M06 T2

G43 H02

S2000 M03

G81 X30.0 Y40.0 Z-5.0 R1.0 F150

(Tool Change to T2 for Roughing)

M06 T2

“`

2. Test the Program with a Simulation

Before running the program on an actual CNC machine, it’s crucial to simulate the toolpath using CAM software or machine simulators. This helps detect potential collisions or errors that could damage the machine.

3. Optimize Feed Rates and Spindle Speeds

Optimizing feed rates and spindle speeds will improve cutting efficiency and tool life. The right speed and feed depend on factors such as the material of the workpiece, the tool type, and the cutting depth.

4. Include Safety Codes

Always include safety codes such as M05 (spindle stop), M30 (program end), and G28 (machine home position) to ensure that the CNC milling machine resets to a safe state after completing its operations.

5. Set Work Offsets Correctly

Ensure that your work offsets are set properly for each part you machine. Using G54-G59 coordinates helps in switching between different fixtures or setups, thus saving time and maintaining precision.

CNC Programming Tools and Software

Several software tools help in creating CNC milling programs. CAD/CAM software such as Fusion 360, Mastercam, and SolidWorks are widely used for designing parts and generating G-code.

1. CAD Software for Designing Parts

Computer-Aided Design (CAD) tools like AutoCAD, SolidWorks, and Fusion 360 help you create a digital model of the part you wish to manufacture.

2. CAM Software for Generating G-code

CAM (Computer-Aided Manufacturing) software translates CAD models into G-code. Programs like Fusion 360, Mastercam, and SolidCAM help create efficient tool paths and automatically generate G-code based on the geometry of your model.

FAQs

1. What is G-code, and why is it important for CNC programming?

G-code is the standard language used in CNC programming to control the movements of the machine. It tells the CNC where to move, how fast, and what path to follow, making it crucial for precision machining.

2. How can I set tool length compensation?

Tool length compensation is set using G43 followed by H and the tool number. This ensures that the CNC machine correctly adjusts for the different lengths of each tool.

3. What is the difference between G90 and G91?

G90 sets the machine to absolute positioning mode, where coordinates are defined from a fixed origin. G91 is for incremental positioning, where each coordinate is relative to the previous position.

4. How can I simulate a CNC program?

You can use CAM software like Fusion 360 or dedicated CNC simulators to visualize the toolpath and detect any errors before actual machining.

5. Why do I need work offsets like G54?

Work offsets help define the reference point on the workpiece. Using offsets like G54-G59 lets you use multiple parts in a single setup, each with its own reference point, saving time and increasing productivity.

Conclusion

Writing a CNC program for milling involves understanding G-code, work offsets, tool changes, and machining cycles. By mastering these concepts, you gain the ability to create precise, efficient programs tailored to your specific milling needs. The tools and techniques mentioned here—like using the right work offsets, optimizing feed rates, and compensating for tool lengths—are all critical for creating effective CNC milling programs.

With dedication and practice, programming a CNC milling machine can be highly rewarding. Whether you’re producing engine parts, tools, or custom prototypes, the ability to create your own CNC programs adds an element of control and creativity to the manufacturing process.