Summary:

CNC machine centers are complex systems requiring precise calculations for optimal performance, especially when it comes to spindle power during full load cutting. Accurately calculating spindle power is crucial for efficiency, tool life, and cutting quality. This article offers insights into spindle power calculation, factors affecting spindle performance, and how to optimize spindle usage in full load conditions. Whether you’re new to CNC machines or an experienced operator, this guide is essential for ensuring that your machine runs smoothly and efficiently.

Introduction

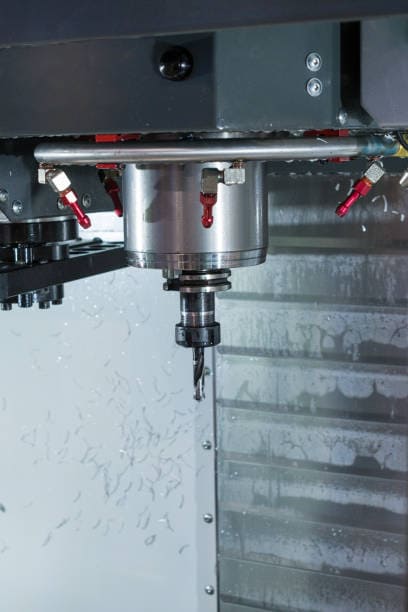

CNC machine centers are at the core of modern manufacturing processes, providing unparalleled precision and automation. However, one of the most important elements in these systems is the CNC spindle motor. It is responsible for cutting and shaping materials, and its power must be calculated accurately, especially during full load cutting. Understanding spindle power and how it relates to different CNC operations is essential for improving the quality of your machining work.

Understanding CNC Spindle Power

Spindle power in CNC machining refers to the energy that the CNC spindle motor provides during cutting operations. This power is directly tied to the performance of the CNC router spindle and determines how well it can cut through materials, especially under full load conditions. To maximize the spindle’s effectiveness, you need to understand the parameters that influence its power output.

Defining Spindle Power in CNC Machining

Spindle power is essentially the torque and speed of the spindle, working in tandem to perform cutting operations. High spindle power allows the CNC machine to cut through tougher materials, while lower spindle power is more suited for delicate and intricate cuts. Ensuring the correct power for your spindle CNC operations is vital for both efficiency and the lifespan of your CNC spindle motor.

Importance of Accurate Spindle Power Calculation

Accurate spindle power calculation is crucial because it directly affects the machine’s cutting capabilities, quality, and the wear and tear on the spindle motor. Overestimating or underestimating the required power can lead to suboptimal performance, tool breakage, or even spindle failure. Proper spindle power ensures smooth cuts, higher production rates, and less machine downtime.

The Basics of CNC Machine Centers

CNC machine centers come in various configurations, and their spindle motors are one of the most vital components. CNC router spindle motors vary in power, depending on the material and workload they are designed to handle. Whether you are working with a single spindle CNC machine or a multi-spindle CNC machine, understanding the basics of these machines helps you calculate the appropriate spindle power for full load cutting.

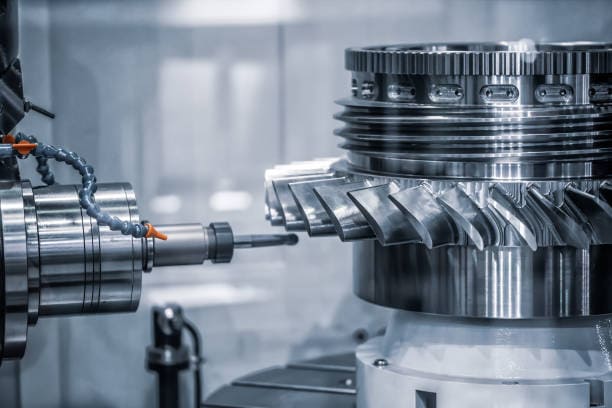

Types of CNC Spindles and Their Applications

CNC spindles come in several varieties, including air-cooled, water-cooled, and electric spindles. Each has its own advantages depending on the type of material being cut and the environment in which the machine operates. For instance, a water-cooled spindle for CNC offers better cooling efficiency during long operation times, making it suitable for heavy-duty tasks. CNC router spindles are commonly used in woodworking, while multi-spindle CNC machines are designed for high-volume production environments.

Factors Influencing CNC Spindle Performance

Several factors affect CNC spindle performance, including material type, feed rate, cutting speed, and the machine’s overall condition. The spindle’s power rating should be matched to the material’s hardness and the complexity of the cuts required. Additionally, proper maintenance of the spindle motor can significantly influence its long-term performance.

Calculating Spindle Power for Full Load Cutting

When a CNC machine is operating under full load, the spindle is under the most stress. It’s important to calculate the spindle power accurately to ensure optimal performance and avoid machine damage. Below is a step-by-step guide on how to calculate spindle power for full load cutting.

Step-by-Step Guide to Power Calculation

To calculate the spindle power required for full load cutting, you need to consider factors such as cutting force, spindle speed, and material hardness. Here’s a basic formula for calculating spindle power:

| Parameter | Formula | Description |

|---|---|---|

| Spindle Power (P) | P = (T × N) / 9550 | Where T is torque (Nm), N is spindle speed (RPM), and 9550 is a constant to convert to kW. |

This formula helps estimate the power required based on the spindle’s torque and speed. However, it’s important to also factor in cutting forces, material type, and the cutting environment to get the most accurate calculation.

Tools and Formulas for Spindle Power Estimation

There are several online tools available to help you estimate spindle power based on various inputs, such as cutting force, spindle speed, and material hardness. These tools can simplify the process and provide a good starting point for optimizing spindle performance.

Analyzing Full Load Cutting Conditions

Full load cutting occurs when the CNC spindle motor is operating at its maximum capacity, often cutting through hard or thick materials. It’s crucial to understand the conditions that define full load cutting and how to adjust spindle power accordingly.

Defining Full Load in CNC Operations

Full load in CNC operations refers to the point where the spindle motor is working at its highest power capacity to perform cutting. This is typically required for harder materials like metal or for deeper cuts in woodworking. Ensuring that your spindle CNC system is calibrated for full load conditions will help prevent overloading and potential spindle failure.

Impact of Material Type on Spindle Power

The material being cut plays a significant role in determining the spindle power needed. For instance, softer materials like wood require less power compared to harder materials like aluminum or steel. Calculating the spindle power based on the material type ensures that your CNC router spindle motor can handle the task without strain.

Calculating Spindle Power for Woodworking CNC Machines

In woodworking, spindle power calculations differ slightly due to the nature of the material. Wood is less dense than metals, so less power is typically required. However, the complexity of the cuts and the type of wood can influence the necessary spindle power.

Step-by-Step Calculation Guide

To calculate spindle power for woodworking CNC machines, you can use the same basic formula outlined earlier, adjusting for the wood’s hardness and the type of cuts being made. Here are the key factors to consider:

- Wood Type (softwood vs. hardwood)

- Feed Rate

- Cutting Depth

These factors will help you determine the correct spindle power to ensure precise and efficient cuts.

Tools and Formulas for Power Calculation

In addition to the basic formula, several specialized calculators are available for woodworking CNC machines. These calculators allow you to input wood-specific variables, such as moisture content and grain direction, to get a more accurate spindle power estimate.

Optimizing Spindle Power Usage

Once you’ve calculated the required spindle power for full load cutting, it’s important to optimize its usage to maximize efficiency and reduce wear on the spindle motor. Here are a few tips to ensure you’re using your CNC router spindle motor efficiently.

Tips for Efficient Power Use During Full Load Cutting

First, always ensure that your spindle motor is properly maintained. Regular lubrication and cooling system checks will keep the spindle running smoothly. Second, use the correct cutting tools for the job. Dull or inappropriate tools can increase the strain on the spindle, requiring more power to achieve the desired results. Finally, monitor the spindle’s performance during operation. If you notice fluctuations in power or overheating, stop the operation and check for potential issues.

Maintenance Practices to Sustain Optimal Power Levels

To maintain optimal spindle power levels, it’s important to regularly inspect and maintain your CNC spindle. This includes checking the spindle bearings, lubrication systems, and cooling mechanisms to prevent any drop in performance. Regular maintenance ensures that your spindle operates at its full power capacity and extends its overall lifespan.

Conclusion

Calculating the spindle power of a CNC machine center by full load cutting is essential for maximizing efficiency, reducing wear, and ensuring high-quality machining. Understanding the factors that influence spindle performance, such as material type and cutting conditions, allows for more accurate power estimation. By following the steps outlined in this guide, you can ensure that your CNC spindle motor operates at optimal power levels, improving both productivity and product quality.

Summary of Key Points:

- Spindle power calculation is essential for efficient CNC machining.

- Material type, feed rate, and spindle speed all influence power requirements.

- Accurate power calculation helps reduce machine wear and improves product quality.

- Regular maintenance of CNC spindles ensures long-lasting performance.

FAQ

What is meant by full load cutting in CNC machining?

Full load cutting refers to the operation where the CNC spindle is working at its maximum capacity to cut through tougher materials or perform deeper cuts.

How does spindle power affect the quality of CNC woodworking?

Spindle power directly impacts the precision and quality of cuts. Insufficient power can lead to rough or incomplete cuts, while excessive power can cause damage to the material.

Can spindle power be adjusted according to material hardness?

Yes, spindle power should be adjusted based on the hardness of the material being cut. Harder materials require more power, while softer materials require less.

What are common mistakes when calculating spindle power?

Common mistakes include underestimating the power required for harder materials and failing to account for factors such as cutting depth and feed rate.

Where can I find tools for spindle power calculation?

Several online tools and calculators are available that allow you to input key variables, such as material type and spindle speed, to estimate spindle power accurately.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.