If you are considering expanding your capabilities in manufacturing or DIY projects, the question often arises: Is a CNC machine a good investment? CNC (Computer Numerical Control) machines are powerful tools used in woodworking, metalworking, plastic manufacturing, and more. These machines offer precision, efficiency, and versatility that traditional manual machines simply cannot match. But investing in a CNC machine involves a significant amount of money, so it’s essential to know if it’s worth it for your needs. In this comprehensive guide, we will explore the costs, benefits, and considerations of owning a CNC machine to help you make an informed decision.

Understanding CNC Machines: What Makes Them Special?

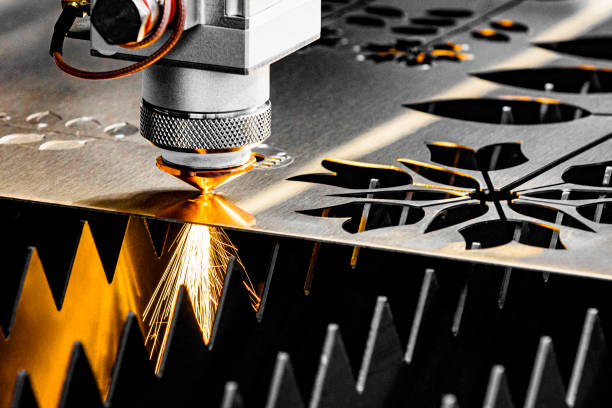

A CNC machine is a computer-controlled manufacturing device capable of cutting, drilling, milling, and shaping a variety of materials. CNC machines are popular in both hobby and professional workshops due to their ability to automate complex tasks that would be challenging and time-consuming when done manually.

Key Features of CNC Machines

- Precision and Accuracy: CNC machines can consistently make cuts within a very narrow tolerance range. This makes them ideal for creating complex parts.

- Automation: Unlike manual tools, CNC machines operate based on programmed instructions, allowing for repeatable accuracy without needing manual adjustments for every part.

- Versatility: CNC machines can work with various materials, including wood, metal, plastics, and composites, providing a wide range of applications.

- Reduced Labor: With CNC, a single operator can oversee multiple machines, reducing the amount of labor required.

The combination of these features means that CNC machines are well-suited for both mass production and highly detailed one-off projects.

Image Credit: 24000RPM 3.2KW ER20 Water-Cooled Spindle

Types of CNC Machines Available

There are several types of CNC machines available, each designed for different applications and materials. Below, we’ll explore some of the most common types:

1. CNC Routers

CNC routers are perhaps the most popular CNC machines for hobbyists and small workshops. They are great for cutting wood, plastic, and soft metals.

- Applications: Furniture making, sign production, cabinetry, and DIY projects.

- Pros: Versatile, easier to set up, and relatively affordable.

- Cons: Not suitable for hard metals.

2. CNC Mills

CNC mills are more robust machines capable of cutting hard metals like steel and aluminum. These machines are used in manufacturing settings where precision and heavy-duty operations are necessary.

- Applications: Metal part fabrication, automotive and aerospace components.

- Pros: High precision and the ability to cut tough materials.

- Cons: Larger and more expensive compared to CNC routers.

3. CNC Lathes

CNC lathes are used primarily for cylindrical parts. These machines can turn and cut material into various symmetrical shapes, making them perfect for parts like shafts and pistons.

- Applications: Automotive parts, piping, threaded components.

- Pros: Excellent for turning and shaping round parts.

- Cons: Limited in scope compared to milling machines and routers.

Image Credit: 1.5KW ER11 Round Air-Cooled Spindle

Benefits of Investing in a CNC Machine

1. Improved Efficiency and Productivity

One of the primary advantages of CNC machines is their ability to increase production efficiency. These machines can run continuously, producing parts with a consistent level of quality. In a professional manufacturing setting, this means increased output and fewer wasted materials.

2. Scalability for Business Growth

If you are running a small shop, adding a CNC machine can allow you to take on more orders. It scales your production without needing to hire extra workers or drastically change your workflow.

For instance, adding a CNC machine equipped with a powerful 24000RPM 0.8KW ER11 Water-Cooled Spindle provides the reliability needed to increase output while maintaining product quality.

3. High Quality and Precision

CNC machines offer unparalleled precision. Unlike manual processes that are subject to human error, CNC-controlled machines follow the same programmed path every time. This guarantees uniformity across all parts, which is essential for applications like automotive components or aerospace parts where tolerances must be exact.

4. Versatility in Material Handling

CNC machines are capable of working with a wide range of materials. They can cut and mill everything from hard metals like steel to softwoods, plastics, and even composites.

- Wood: Commonly used for making cabinets, signs, and furniture.

- Metal: CNC mills can precisely machine aluminum and steel parts.

- Plastics and Composites: CNC routers and mills are used to create plastic parts or composite components for various industries.

Costs Involved in CNC Machine Ownership

Investing in a CNC machine involves more than just the upfront cost. You should consider setup costs, ongoing maintenance, software expenses, and tooling costs as well.

1. Initial Purchase Cost

| Machine Type | Cost Range ($) |

|---|---|

| CNC Router | 1,500 – 10,000 |

| CNC Mill | 5,000 – 50,000 |

| CNC Lathe | 7,000 – 70,000 |

These costs can vary depending on factors such as brand, size, and capabilities.

2. Setup Costs

- Electrical Setup: You may need a dedicated power supply or additional wiring to handle the electrical load of a CNC machine.

- Tooling: The cutting tools, end mills, and drill bits are necessary and vary depending on the material and complexity of your work.

- Software Costs: You need CAD and CAM software to operate a CNC machine. Popular options like Fusion 360 or VCarve may involve one-time or subscription fees.

3. Maintenance and Upkeep

CNC machines require regular maintenance to function efficiently. Maintenance costs include:

- Lubrication: Keeping the ball screws and linear guides lubricated ensures smooth operation.

- Tool Replacement: Tools wear out and need replacement, especially when used for hard materials.

- Servicing: Professional service is needed periodically to calibrate and inspect the machine.

Image Credit: 24000RPM 0.8KW ER11 Water-Cooled Spindle

Pros and Cons of Owning a CNC Machine

Advantages

- Automation and Efficiency: Automates tasks that are labor-intensive when done manually, saving time and costs.

- Versatility: Able to handle a range of materials and create complex parts.

- Reduced Waste: With computer precision, CNC machines minimize errors, resulting in less wasted material.

Disadvantages

- High Initial Investment: CNC machines are expensive, especially if you need larger or more complex machinery.

- Learning Curve: Learning how to operate and program a CNC machine can take time. Although there are resources available, some beginners may find it challenging.

- Maintenance: CNC machines need regular maintenance, which can be costly over time if not handled properly.

Who Should Invest in a CNC Machine?

1. Small Business Owners

If you own a small fabrication shop or woodworking business, a CNC machine can greatly improve efficiency and scalability. For instance, adding a 24000RPM 3KW ER20 Water-Cooled Spindle allows you to cut parts quickly and with a high level of detail, which can be pivotal for custom furniture makers or cabinet shops.

2. Hobbyists and DIY Enthusiasts

Hobbyists can also benefit significantly from a CNC router or a small CNC mill. These machines offer the ability to create custom parts for personal projects, from custom engravings to small metal components. However, the initial investment can be high for a hobbyist.

3. Manufacturing Companies

For manufacturing companies, CNC machines are often indispensable. They ensure the consistency and precision needed for mass production. Whether in aerospace, automotive, or electronics, the value added by CNC technology is immense.

Return on Investment (ROI) Considerations

Calculating the Return on Investment (ROI) for a CNC machine involves considering both cost savings and revenue generation.

1. Labor Savings

- Reduced Staffing Needs: A CNC machine can do the work of multiple laborers, allowing you to reduce staffing costs.

- Skilled Labor vs. Automation: With a CNC machine, the need for highly skilled manual machinists is minimized, as programming skills take precedence.

2. Material Efficiency

- Minimized Waste: CNC machines produce less waste, as cuts are precise, and errors are minimized.

- Reuse of Offcuts: Leftover materials can often be reused, reducing overall material costs.

3. Increased Production Capacity

A CNC machine can significantly increase your production capacity, allowing you to take on more orders or create more detailed products that would not be feasible with manual labor. This scalability is essential for businesses looking to grow.

FAQs

1. Is a CNC machine a good investment for small shops?

Yes, for small shops, investing in a CNC machine can increase efficiency, reduce labor costs, and improve the quality of finished products, making it a worthwhile investment.

2. How much does a CNC machine cost?

The cost of a CNC machine varies significantly, from $1,500 for entry-level CNC routers to $50,000 or more for industrial-grade mills and lathes.

3. What are the main benefits of CNC machines over manual machines?

CNC machines offer precision, automation, and versatility, allowing you to produce parts faster, with fewer errors, and with more complex geometries compared to manual machines.

4. How can CNC machines save on labor costs?

CNC machines automate production, reducing the need for manual labor and allowing a single operator to manage multiple machines simultaneously.

5. What industries benefit the most from CNC machines?

Automotive, aerospace, medical device manufacturing, and furniture production industries benefit significantly from CNC machines due to their precision and ability to handle large-scale production.

Conclusion

Investing in a CNC machine is a significant decision that can lead to increased productivity, reduced costs, and scalability for your business or personal projects. While the upfront cost can be high, the benefits in terms of precision, efficiency, and versatility make CNC machines an invaluable asset for a wide range of industries. Whether you’re a hobbyist, a small business owner, or a manufacturer, the potential gains from a CNC machine can far outweigh the initial investment. If you are ready to explore CNC spindles that suit your needs, visit spindlemotorshop.com for a wide range of high-quality options to get started.