Introduction

The world of precision cutting has evolved dramatically in recent years. Enthusiasts and professionals alike have encountered numerous tools, each designed for a specific need. Two names that frequently come up are Cricut machines and CNC machines. But this often brings up an important question: Is a Cricut a CNC machine? To understand the difference and similarities between these popular cutting tools, it is essential to delve into the functions, features, and applications of each.

In this article, we will explore what makes a Cricut machine and what a CNC machine is. We will compare them and ultimately help you understand if these tools are one and the same. For those in crafting, design, or industrial applications, this discussion will be incredibly useful to comprehend the differences and decide which machine may be the right fit for you.

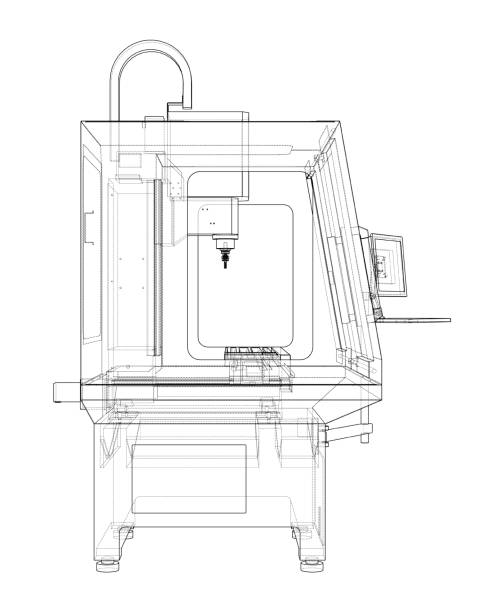

What is a CNC Machine?

A CNC machine—short for Computer Numerical Control—is an automated control system used for precise machining. CNC machines are prevalent in industries like automotive, aerospace, manufacturing, and even in smaller machine shops. The core idea of CNC involves a computerized control system that directs cutting tools based on pre-programmed sequences. This allows for incredible precision and automation, ideal for complex tasks that need detailed cutting and engraving.

CNC machines come in various shapes and sizes. Some common types include CNC milling machines, CNC lathes, and CNC routers, all of which use diverse spindle motors for different purposes. CNC machines can cut wood, metal, plastic, and more. They are highly capable machines designed to fulfill high precision, high productivity needs.

To learn more about different types of CNC spindles, visit the CNC Spindle Motors page.

How Do CNC Machines Work?

CNC machines operate by following a set of commands written in G-code, which serves as instructions that tell the machine where and how to move. The G-code helps direct the machine’s path, speed, and specific tasks like engraving or drilling. CNC machines can function autonomously, which helps manufacturers produce products quickly and accurately with minimal human intervention.

The central part of the CNC machine is its spindle motor. The spindle helps rotate the tool or workpiece, depending on the application. This motor must be highly reliable as it determines how smoothly and precisely the machine cuts. Some commonly used spindles include water-cooled spindles, such as the 24000RPM 3KW ER20 Water-Cooling Spindle, known for their efficiency in high-speed operations.

Key Features of CNC Machines

- High Precision: Achieves a high level of accuracy, ideal for detailed projects.

- Automation: Machines can run without direct human control.

- Versatility: Capable of working with various materials such as wood, metals, plastics, and more.

What is a Cricut Machine?

A Cricut machine is a versatile cutting tool that is primarily used by crafters for personal and small-scale projects. Cricut machines allow users to create designs that are precisely cut out of materials like paper, vinyl, fabric, and lightweight woods. Unlike CNC machines, Cricut machines are often used for crafting and personalization. They are a favorite among scrapbookers, card makers, and custom T-shirt printers.

Cricut machines are user-friendly, often marketed for home and small business use. They work based on digital designs, which can be uploaded through the companion Cricut software. Users select the type of material they are working with, and the machine adjusts the blade to cut accordingly.

How Does a Cricut Work?

Cricut machines operate by using a small, replaceable blade that moves along pre-defined paths to cut materials. The paths are generated from digital files designed by the user. Unlike CNC machines that can handle heavy-duty materials, Cricuts are designed for softer materials and have a simpler blade and motor system.

Key Features of Cricut Machines

- Easy to Use: Designed for home users and small businesses.

- Versatility in Crafting: Used for cutting materials like paper, vinyl, and fabric.

- Cost-Effective: Cricut machines are significantly cheaper compared to CNC machines, making them accessible to a wider audience.

Comparing Cricut Machines to CNC Machines

1. Purpose and Use Cases

CNC machines are generally used for industrial purposes. They are capable of handling heavy-duty tasks such as engraving, milling, and drilling metals, plastics, and woods. Their high precision and power make them suitable for large-scale manufacturing and detailed craftsmanship.

On the other hand, Cricut machines are designed with crafting in mind. They are built for small-scale, personalized projects rather than mass production. Cricuts are frequently used for card-making, personalized decals, and custom fabric designs.

2. Complexity and Precision

CNC machines are well-known for their complexity and can achieve incredible precision, which is crucial for creating machine parts and components. These machines can create elaborate designs, and their spindle motors are calibrated for high accuracy and durability.

A Cricut machine does not offer the same level of complexity. Instead, its primary strength is simplicity. Cricut machines are user-friendly, designed to enable users to complete projects without much technical knowledge.

For those interested in exploring complex CNC projects, tools such as the 60000RPM 1.2KW ER11 Water-Cooled Spindle offer advanced options for more demanding tasks.

3. Types of Motors and Tools Used

- CNC Machines: These machines make use of spindle motors that are either air-cooled or water-cooled, and can vary in power output from as little as 0.8KW to as much as 7.5KW or higher. The type of motor is dependent on the material being worked on and the complexity of the task.

- Cricut Machines: Cricuts use basic cutting blades and rollers. The power output is not as high as CNC machines since they only need to work with softer materials.

Can a Cricut be Considered a CNC Machine?

Technically speaking, a Cricut machine can be classified as a form of CNC machine, as it also uses computerized controls to direct the blade and cut materials along a specific path. The difference, however, lies in the application and the scale of the machine. CNC machines are built for precision manufacturing and heavy-duty use, whereas Cricut machines cater to crafters and personal projects.

While both Cricut and CNC machines utilize digital design files to determine cutting paths, the type of materials and the scale of production they are used for significantly differ.

Advantages of CNC Machines Over Cricut

1. Industrial Capability

CNC machines are capable of handling a much broader range of materials. From metals to wood, CNC machines are widely applicable in industries ranging from furniture making to automobile parts. They are equipped with spindle motors such as the 24000RPM 4.5KW ER20 Water-Cooled Spindle, which can work continuously without overheating.

2. High Customization and Precision

With the help of advanced software and spindle motors, CNC machines can be highly customized. Whether you need an intricate part made from aluminum or a wooden design engraved with high accuracy, a CNC machine offers an unparalleled level of precision and customization.

3. Durability and Heavy-Duty Cutting

CNC machines are built for continuous use and can run 24/7 in production facilities, unlike Cricuts, which are only suitable for limited use. CNC machines are also capable of cutting harder materials without any issues.

When Should You Choose a Cricut?

1. For Crafting and Small Businesses

If you are an enthusiast or a small business owner working on crafting, Cricut is an ideal choice. It offers an easy interface, allowing you to create various designs with materials like vinyl, cardstock, and fabric.

2. Affordability

A Cricut is more affordable compared to a CNC machine, making it a go-to option for beginners or small-scale businesses.

3. Ease of Use

Cricut machines come with built-in software, allowing beginners to get started right away without learning complex design programs. It’s a simple, plug-and-play kind of device that delivers quick results.

Conclusion

So, is a Cricut a CNC machine? The short answer is yes, but with a twist. Both Cricut machines and CNC machines use computerized control for cutting, but their capabilities, complexities, and applications vary significantly. Cricut machines are best suited for crafting and small-scale personalization, while CNC machines are made for precision and industrial-level manufacturing.

If you’re someone looking to start small, Cricut will give you an excellent gateway into the world of digital design and crafting. However, if you aim to create more complex parts, handle tougher materials, and need a high degree of customization, CNC machines are the way to go.

For further details on CNC spindles that can boost your project capabilities, take a look at our CNC Spindle Motors.

FAQs

1. What type of materials can a Cricut machine cut?

Cricut machines are primarily used for softer materials such as paper, vinyl, fabric, and balsa wood. They do not handle metals or hard plastics like CNC machines.

2. Can I use a Cricut for industrial applications?

Cricut machines are not ideal for industrial applications. They are best suited for crafts, scrapbooking, and small business use.

3. What types of CNC machines are there?

There are various types of CNC machines, such as CNC mills, CNC routers, and CNC lathes. Each type is specialized for different machining purposes.

4. How much does a CNC machine cost compared to a Cricut?

CNC machines tend to be much more expensive, often costing thousands of dollars, while Cricut machines are more affordable, making them accessible to hobbyists.

5. Can Cricut software create G-code?

Cricut machines use their proprietary software that doesn’t output standard G-code, unlike most CNC machines, which rely on G-code for programming.

6. Which is better for intricate designs: Cricut or CNC?

CNC machines offer a higher precision level, making them more suitable for intricate designs, especially on tougher materials. However, Cricut is easier for less technical, artistic designs on softer materials.