Is CNC Healthy?

CNC technology has revolutionized the manufacturing industry, bringing unprecedented accuracy, efficiency, and versatility to a wide variety of projects. As CNC machines become more widespread, many wonder if using CNC is “healthy”—not just in terms of physical safety, but also economically and environmentally. In this comprehensive guide, we explore the health aspects of using CNC machines and how these advanced technologies contribute to a sustainable and efficient working environment. We will also delve into the key features and practices to ensure that CNC technology remains a healthy addition to both small workshops and large manufacturing environments.

Understanding CNC and Its Impact on Work Health

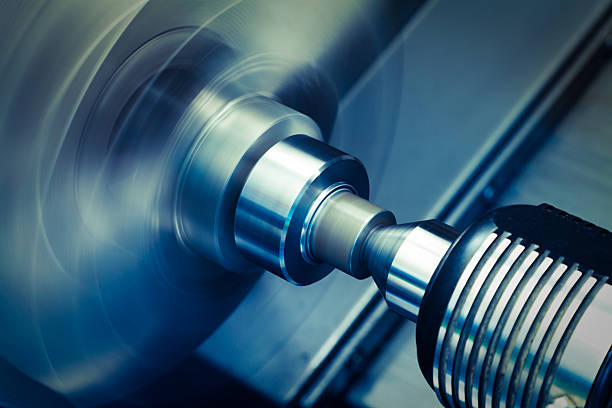

CNC (Computer Numerical Control) machines have transformed traditional manufacturing by automating what was once labor-intensive, manual processes. With their ability to cut, drill, and shape materials like wood, metal, and plastic, CNC machines enhance precision and repeatability while significantly reducing human intervention. But how does this automation influence health?

The use of CNC machinery in the workplace can lead to healthier working conditions by reducing the physical strain that often accompanies manual machining. Instead of using manual tools and muscle power, operators use computer software to control spindles, cutting tools, and the various axes of movement involved in CNC machining. This helps reduce the risk of repetitive strain injuries and other physical ailments commonly associated with manual work.

For high-precision CNC operations, the 4.5KW ER32 Air-Cooled Spindle is an ideal component, providing consistency and power while minimizing the effort required from the operator.

Physical Safety in CNC Operations

1. Reducing Physical Strain

One of the most obvious health benefits of using CNC machines is the reduction of physical strain. Manual machining requires considerable physical strength and endurance, especially for tasks involving repetitive actions or heavy materials. CNC machines alleviate this strain by automating these processes.

- Automation: The computer and mechanical systems take over tasks that require repetitive force.

- Reduction of Lifting: Large parts can be handled using robotic arms or material feed systems, reducing the need for manual lifting.

This contributes to lower rates of workplace injury, which is particularly important in reducing musculoskeletal disorders that can develop from years of repetitive physical work.

2. Enhanced Operator Safety

The operator’s role in CNC machining shifts from manual manipulation of materials and tools to overseeing the machine’s actions. This shift enhances workplace safety by minimizing the risk of injuries such as cuts, burns, or entrapment in moving parts.

- Enclosed Work Area: Most CNC machines come with enclosed work areas, ensuring that moving parts are safely out of reach.

- Automatic Shut-Off: CNC systems can be programmed to shut off in the event of a malfunction, thereby preventing potential accidents.

For those working with highly intricate parts, the 6KW ER32 Air-Cooled Spindle offers precision that reduces human error, enhancing safety and quality.

Mental Health and Stress Reduction

1. Lower Stress Levels Through Automation

Manual machining often involves considerable stress. The pressure to meet production quotas, the risk of making errors, and the physical demands of machining can all contribute to a stressful working environment. CNC machines, however, mitigate these factors by automating most of the processes.

- Repeatability: CNC machines are programmed to perform the same task with precision each time, reducing the stress of making manual adjustments and minimizing error.

- Error Reduction: Automated G-code programming ensures that every part produced is consistent, which means less stress for operators regarding potential reworks or scrapped parts.

2. Improved Work-Life Balance

With automation taking on much of the heavy lifting, CNC operators have more time for other tasks and fewer late-night shifts for manual production runs. This improvement in work-life balance can lead to a healthier workforce overall.

Environmental Health Impact of CNC Machining

While the term “healthy” often applies to personal well-being, the impact of CNC machining on the environment is also worth considering. CNC technology can contribute to a more sustainable manufacturing environment, which in turn has health benefits for communities.

1. Reduction in Material Waste

CNC machining is renowned for its precision, which means that less material is wasted compared to manual machining. The machines cut exactly where they are supposed to, minimizing the amount of scrap material produced.

- Precision Cutting: Reduces overcuts and ensures that materials are used efficiently.

- Recycling: Most CNC machines allow for the easy collection of metal chips and other remnants, which can then be recycled.

Reducing waste not only saves money but also lessens the environmental burden of producing new raw materials, leading to an overall healthier environment.

2. Efficient Use of Resources

CNC machines are designed to optimize resource use, including electricity, cutting fluids, and tools. By maximizing the use of each tool and minimizing idle time, CNC machines consume fewer resources and generate less environmental waste.

For example, the 3.5KW ER20 Air-Cooled Spindle is energy-efficient, providing ample power while optimizing electricity consumption during machining tasks.

Economic Health: CNC for Business Efficiency

1. Cost Savings Through Efficiency

CNC technology enables businesses to save on production costs by reducing waste and enhancing efficiency. While the initial cost of CNC equipment can be high, the long-term benefits, such as labor savings and reduced material costs, make it a sound investment.

- Reduced Labor Costs: Less manpower is required for operating multiple machines simultaneously.

- Enhanced Productivity: A CNC machine can run continuously with minimal supervision, increasing productivity without added costs.

2. Competitive Advantage

Companies using CNC technology often have a competitive edge over those relying solely on manual processes. The ability to deliver precise, high-quality parts at a consistent rate ensures that CNC-equipped manufacturers stay ahead of the curve.

- Quicker Turnaround: CNC’s precision means less time is wasted in reworking parts or addressing errors.

- Scalable Production: CNC machines make it easier for businesses to scale up production without a proportional increase in labor or material costs.

Ergonomics of Working with CNC Machines

1. Improved Workplace Ergonomics

The physical layout of a CNC workspace is often more ergonomically friendly than that of a traditional manual machining station. The operator typically interacts with a computer interface, and the actual cutting and milling are done behind protective barriers.

- Reduced Need for Manual Handling: The automation of part movement within the machine reduces the need for manual handling.

- Optimized Control Panel Placement: CNC workstations often have adjustable control panels that can be positioned at an optimal height, preventing operator fatigue.

2. Training for Safe Use

One important aspect of maintaining a healthy working environment with CNC machines is proper training. Operators must be well-versed in both the safe use of the machine and the proper procedures for maintenance.

- Safety Training: Includes emergency shutdown procedures, routine checks, and correct operation methods.

- Maintenance Knowledge: Knowing how to inspect and maintain a CNC machine reduces the chances of a malfunction, which can enhance safety and prevent accidents.

Ensuring Healthy CNC Practices

1. Ventilation and Air Quality

CNC machining generates metal dust, chips, and fumes that could be harmful if inhaled over long periods. Proper ventilation is a must for maintaining air quality and ensuring the health of workers.

- Dust Collection Systems: Dust extractors help remove particles that are generated during the cutting process, keeping the air clean.

- Regular Monitoring: Monitoring air quality and using the appropriate PPE (personal protective equipment) like masks ensures that operators are not exposed to harmful substances.

2. Safe Use of Cutting Fluids

Some CNC processes require cutting fluids for lubrication and cooling. These fluids, if improperly handled, can be hazardous. Ensuring that operators use and dispose of these fluids correctly is crucial for maintaining a healthy environment.

- Proper Disposal: Always dispose of cutting fluids in line with environmental regulations.

- Use of Protective Gear: Gloves and eye protection should be used when handling cutting fluids.

Frequently Asked Questions (FAQs)

1. How does CNC improve workplace health?

CNC improves workplace health by reducing physical strain, enhancing operator safety through automation, and minimizing repetitive manual tasks that could lead to musculoskeletal issues.

2. Are CNC machines environmentally friendly?

Yes, CNC machines are environmentally friendly in several ways, including reducing material waste, optimizing resource use, and making it easier to recycle materials.

3. What are the safety precautions for CNC machining?

Safety precautions include using enclosed work areas, proper training, adequate ventilation, and ensuring cutting fluids are handled correctly.

4. Can CNC machining reduce stress for operators?

Yes, CNC machining reduces operator stress by automating tasks, minimizing error rates, and reducing the need for manual intervention, thereby providing a more relaxed working environment.

5. How can CNC technology improve business efficiency?

CNC technology improves business efficiency by reducing labor costs, ensuring repeatable quality, and enabling faster turnaround times.

Conclusion

CNC machining offers significant health benefits—both physical and mental—by reducing physical strain, automating dangerous tasks, and improving ergonomics in the workspace. Environmentally, CNC machines are more efficient and generate less waste, contributing to a healthier planet. Moreover, from an economic standpoint, CNC machines enhance productivity, cut costs, and give companies a competitive edge. By understanding and addressing both the human and environmental factors associated with CNC machining, manufacturers can ensure that CNC is indeed a “healthy” choice for both workers and businesses.

For more insights and to explore a wide range of CNC spindles that can further enhance your CNC machining experience, visit SpindleMotorShop. Here, you can find spindles suited for various applications, helping you maintain both efficiency and precision in every project