Edge Bander Spindle Categories

LEARN MORE

Introduction

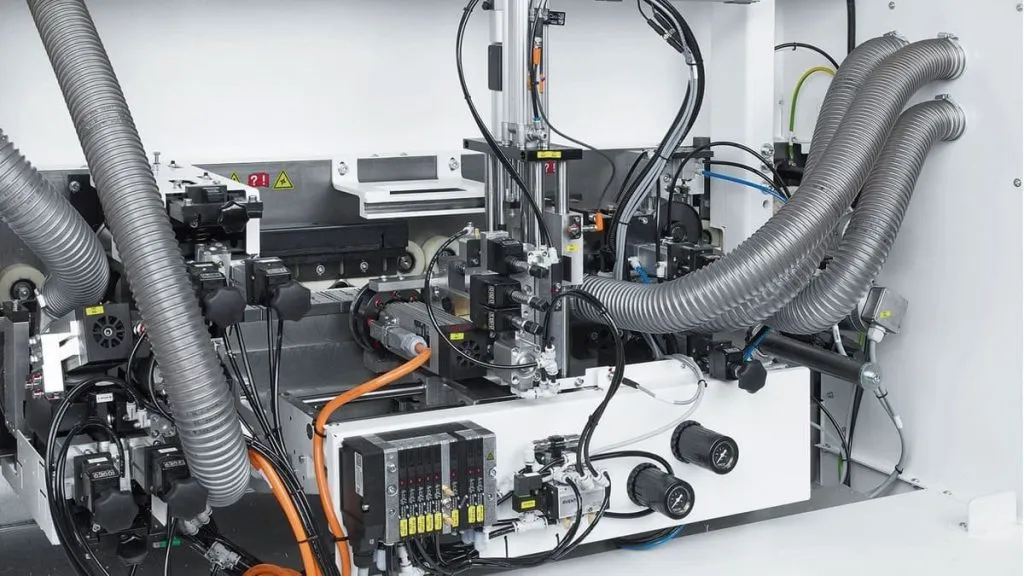

The role of pre-milling motor: The pre-milling process is usually the first step in edge banding. Its main purpose is to preliminarily process the edge of the plate before edge banding to remove any surface defects or irregularities, thereby laying the foundation for the subsequent edge banding process and improving the surface finish of the edge. This process can reduce the defects that may occur in the subsequent edge banding, such as uneven edge banding, poor glue adhesion, etc. Therefore, the pre-milling process is an indispensable part of the edge banding process.

Parameter

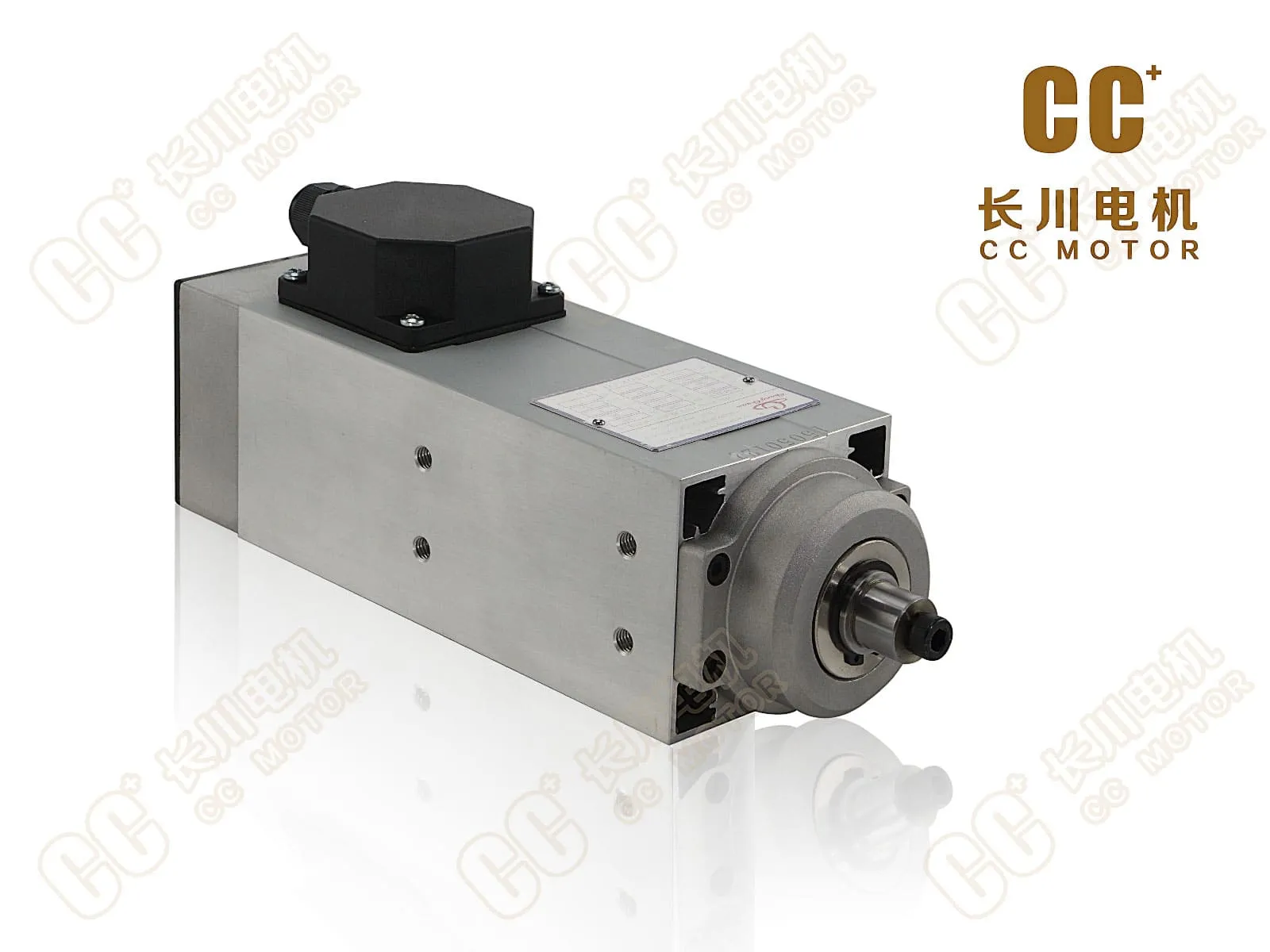

| Model | MF71-5612F | MF60-1509F | MJ55-2212F | MF55-3512F | MF46-18 | MJ55-4012F | MF60-2212F | MJ70-7512FD |

|---|---|---|---|---|---|---|---|---|

| Speed (rpm) | 9000 | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 | 12000 |

| Voltage (V) | 380V/220V | 380V/220V | 380V | 380V/220V | 380V/220V | 380V | 380V/220V | 380V |

| Current (A) | 4.5A/7.8A | 5.6A/9.7A | 7.0A | 11.5A/20A | 4.6A/8A | 8.3A | 5.6A/9.7A | 19A |

| Frequency (Hz) | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Power (KW) | 1.5 | 2.2 | 3.5 | 5.6 | 1.8 | 4.0 | 7.5 | 7.5 |

If you need a spindle with different parameters, please contact us and we will provide you with professional services.

PRODUCTS

High-performance edge bander spindles for beginners & professional