Introduction

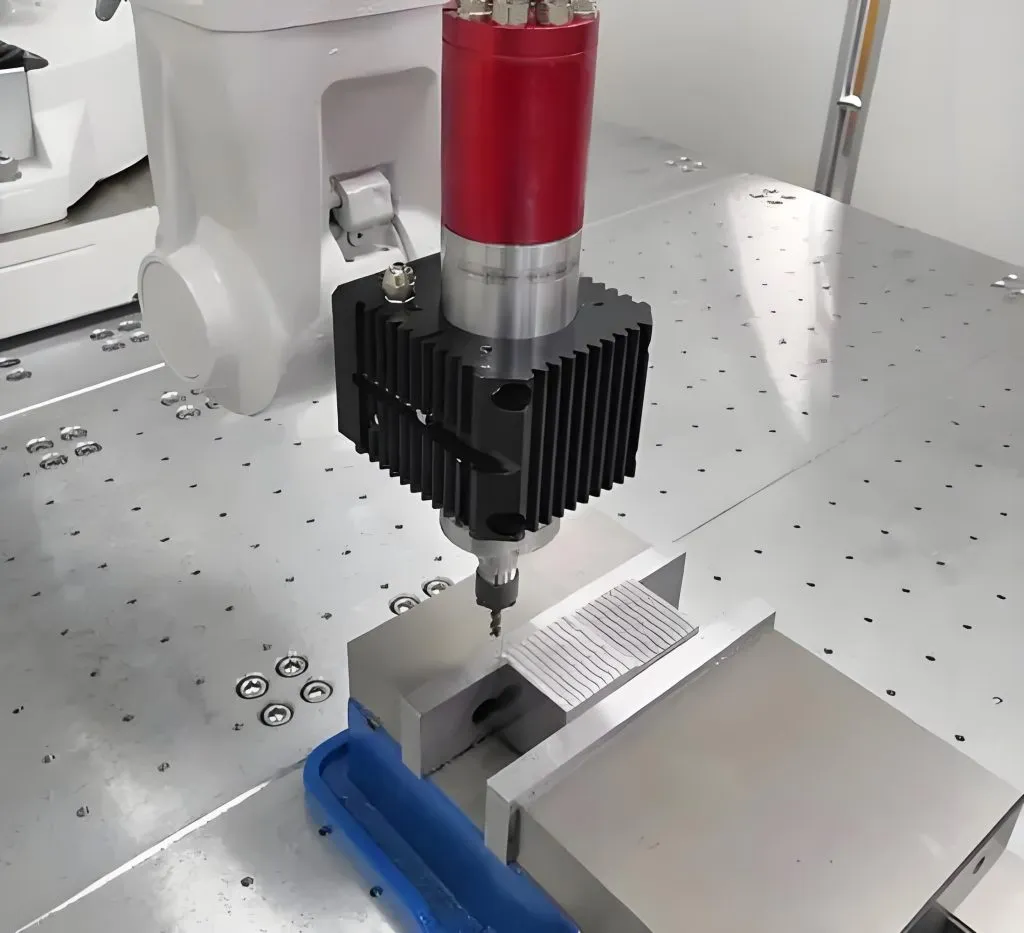

In CNC machining, the electric spindle is a critical component that affects production efficiency and quality. The role of the electric spindle is to drive the rotating tool through the motor, which significantly impacts processing time, surface quality, and overall productivity. This article will explore the various types of CNC electric spindles, their characteristics, and how to choose the right electric spindle to improve your processing technology.

CNC Spindle Structure Type

Materials and Construction

Aluminum alloy vs. stainless steel: Traditionally, the core frame of CNC electric spindles is mainly made of aluminum alloy, which is popular because of its lightweight. However, in recent years, new electric spindles have begun to use stainless steel welded core frames. Stainless steel can reduce the spindle’s size while ensuring the same power and improving the processing accuracy. For example, a traditional 1.5kW spindle size is about Φ80 215mm. The new spindle with a stainless steel welded core frame can be reduced to Φ65 210mm, which is very suitable for engraving machines, although the price is slightly higher.

Cooling Method

Air cooling vs. water cooling: Early low-power CNC electric spindles (usually a few hundred watts) were mainly air-cooled. However, with the development of technology, most engraving machines currently use water-cooled electric spindles. Water-cooled spindles can handle higher power and have the advantage of low noise.

Support Method

Two bearings vs. 3 bearings vs. 4 bearings: The bearing configuration of the electric spindle affects its load-bearing capacity and durability. For processing soft metals, a two-bearing configuration is sufficient; for processing heavy loads such as steel, a three-bearing or four-bearing configuration is more suitable. Electric spindles with power exceeding 1.5kW usually use a three-bearing or four-bearing configuration to ensure processing stability.

Lubrication Method

Oil mist vs. grease: High-speed electric spindles (speed exceeding 24,000 rpm) usually use oil mist lubrication supplied through a dedicated oil circuit. Although the installation and use are complicated, it can effectively reduce wear. For most engraving machines, grease-lubricated electric spindles are sufficient, and the speed range is usually between 6,000 and 24,000 rpm, which can be adjusted by frequency conversion.

Conclusion

In CNC processing, choosing a suitable electric spindle is very important. Different spindle structures, cooling methods, characteristics, support methods, and lubrication methods will directly affect the efficiency and quality of processing. By profoundly understanding and correctly selecting the electric spindle, you can significantly improve the stability and production efficiency of the processing process, thereby gaining an advantage in the fierce market competition.

Summary FAQ Based on the Article

Q1: What is the role of the electric spindle in CNC machining?

A1: The electric spindle drives the rotating tool through the motor, significantly impacting processing time, surface quality, and overall productivity.

Q2: What materials are commonly used to construct CNC electric spindles?

A2: CNC electric spindles are commonly made from aluminum alloy. Still, stainless steel welded core frames are becoming more popular due to their ability to reduce spindle size and improve processing accuracy.

Q3: How does the cooling method affect the performance of an electric spindle?

A3: Air-cooled spindles are used for lower-power applications, while water-cooled spindles handle higher power and operate with lower noise, making them more suitable for advanced applications.

Q4: Why is the bearing configuration important in an electric spindle?

A4: The bearing configuration determines the spindle’s load-bearing capacity and durability, with more bearings needed for processing heavier materials.

Q5: What lubrication methods are used for electric spindles, and how do they differ?

A5: High-speed spindles often use oil mist lubrication to reduce wear, while grease lubrication is sufficient for most engraving machines, with speed ranges adjusted by inverter

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.