Introduction

Spindle drives and axes drives play a critical role in the performance of CNC machines. But what exactly are these components, and how do they contribute to the overall efficiency of CNC operations? Understanding how spindle drives and axes drive function is essential for maximizing precision and productivity in modern manufacturing. In this article, we’ll explore the importance of these drives, their applications, and how they fit into the broader landscape of CNC technology.

This guide will help you better understand the inner workings of CNC machines, with a focus on spindle and axes drives, offering practical insights for professionals, hobbyists, and anyone involved in CNC manufacturing.

The Role of Spindle Drives in CNC Operations

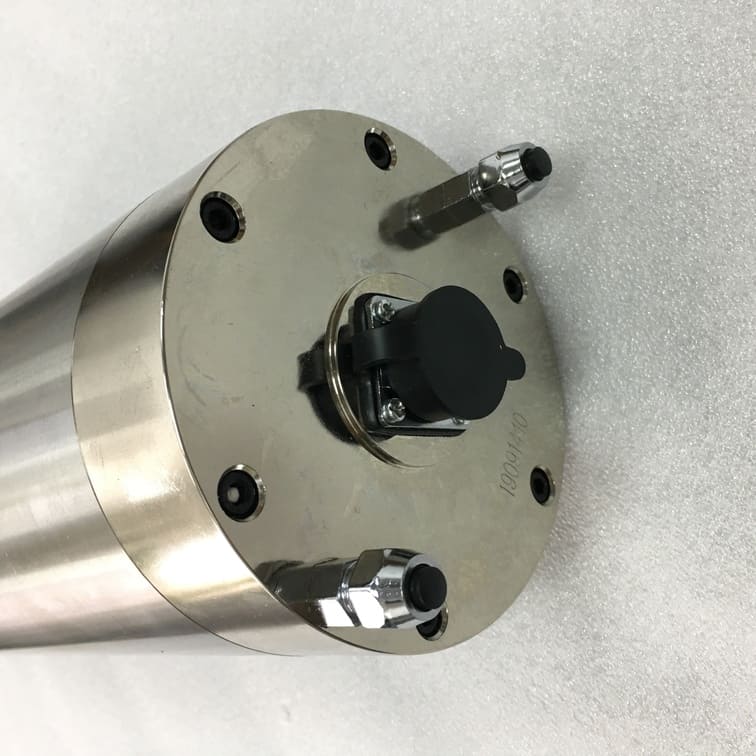

Spindle drives are at the heart of CNC machine operations, controlling the rotational speed and torque of the CNC spindle motor. In a CNC machine, the spindle drive powers the cutting tool, enabling it to rotate at varying speeds depending on the material being cut. This is crucial for ensuring that each project achieves the desired level of precision and efficiency.

Key Functions of Spindle Drives:

- Speed Regulation: Allows for precise adjustments to the spindle speed, depending on the task.

- Torque Control: Maintains the right amount of torque to cut through materials effectively.

- Power Delivery: Provides the necessary energy for continuous and heavy-duty operations in CNC router spindles and other applications.

Types of Spindle Drives and Their Applications

CNC machines use various types of spindle drives depending on the complexity and scale of the operation. Each spindle drive type offers unique advantages suited to specific applications.

| Type | Description | Applications |

|---|---|---|

| DC Spindle Drives | Low-speed precision offers excellent control and torque. | Used in woodworking and delicate operations. |

| AC Spindle Drives | More powerful and efficient with higher speed ranges. | Ideal for metal cutting and industrial applications. |

| Servo Spindle Drives | High precision at high speeds provides better control. | Often used in multi-axis CNC machines. |

Definition and Importance of Axes Drive

While the spindle drive powers the cutting tool, the axes drive controls the movement of the machine’s various axes. These axes control the positioning of the spindle and the material being worked on, making them essential for achieving precise cuts.

Functions of Axes Drives:

- Positioning: Ensures the cutting tool is positioned correctly relative to the workpiece.

- Movement: Controls linear and rotary movement across multiple axes.

- Precision: Key to improving the machine’s overall accuracy and efficiency.

How Axes Drives Improve CNC Machine Precision

CNC machines operate on multiple axes, typically X, Y, and Z, but some advanced machines also include additional axes for more intricate movements. The precision of these movements is heavily dependent on the performance of the axes drive.

Improving Accuracy: Axes drives allow for fine-tuned adjustments to the machine’s position, ensuring each cut is performed with high accuracy.

Enhancing Performance: Smooth transitions between movements reduce vibrations and errors, leading to cleaner, more precise cuts.

Recent Advances in CNC Spindle and Axes Drive Technology

The continuous improvement of CNC machines has led to significant advancements in both spindle and axes drives. These innovations have made modern CNC systems more efficient and capable of handling increasingly complex tasks.

- Variable Frequency Drives (VFDs): Allow more precise control over spindle speed and torque.

- Hybrid Servo Systems: Provide enhanced precision for both spindle and axes drives.

- Predictive Maintenance Software: Monitors the health of the spindle and axes drives, predicting maintenance needs before failures occur.

Motor Types Used in Spindle Drives

The motor is the powerhouse behind every spindle drive, and different motor types offer different benefits depending on the CNC application.

Common Motor Types:

- Brushless Motors: Durable and energy-efficient, suitable for continuous high-speed operations.

- Brushed Motors: Simpler and more affordable, best for smaller projects.

- Induction Motors: Reliable for high-power industrial applications.

Linear vs. Rotary Axes Drives

CNC machines can be equipped with either linear or rotary axes drives, depending on the type of movement required.

- Linear Axes Drives: Responsible for straight-line movements along X, Y, and Z axes. Ideal for tasks like drilling and routing.

- Rotary Axes Drives: Control circular movements, useful for 3D milling and engraving.

Frequently Asked Questions

- What is the difference between spindle drives and axes drives? Spindle drives control the rotation of the cutting tool, while axes drives control the movement of the machine’s components.

- How do spindle drives enhance CNC machine performance? By regulating the speed and torque of the cutting tool, spindle drives ensure efficient and precise cuts.

- What are the main types of spindle drives? DC, AC, and Servo drives, each suited to different applications.

- Why are axes drives important in CNC machines? Axes drives ensure the cutting tool is positioned accurately relative to the material.

- Can spindle and axes drives be upgraded for better performance? Yes, upgrading these drives can improve precision, speed, and efficiency.

Key Takeaways

- Spindle and axes drives are essential for controlling movements in CNC machines.

- Advances in spindle and axes drive technology have improved machine efficiency.

- Proper maintenance and integration of drives ensure long-lasting, precise operations.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.