Introduction

With advancements in CNC (Computer Numerical Control) technology, multi-spindle machines are becoming increasingly popular in various manufacturing sectors. These machines, equipped with multiple spindles, allow for simultaneous machining of several parts, significantly reducing production times. Whether you’re involved in mass production or complex projects, understanding the benefits of CNC multi-spindle machines can dramatically improve your workflow and output.

Understanding CNC Multi-Spindle Machines

The Basics of CNC Multi-Spindle Technology

At its core, a CNC multi-spindle machine features multiple spindles that can operate independently or in tandem, depending on the complexity of the task. Unlike single-spindle machines, where only one tool operates at a time, multi-spindle units can work on different parts simultaneously, boosting efficiency and throughput. This capability makes them ideal for industries where time and precision are of the essence, such as woodworking, metalworking, and electronics manufacturing.

How Multi-Spindle Machines Differ from Single-Spindle Units

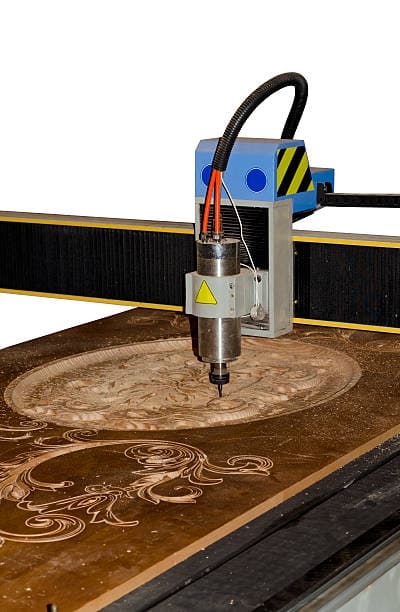

While single-spindle CNC machines are versatile and precise, they often fall short in terms of speed for large-scale production. Multi-spindle machines, on the other hand, can complete multiple operations in parallel, dramatically reducing the time required to finish a project. For example, in a woodworking shop, a multi-spindle CNC router spindle can carve intricate designs on several wooden panels simultaneously, cutting down hours of manual labor and improving overall efficiency.

Key Benefits of CNC Multi-Spindle Machines

Enhanced Productivity and Efficiency

The most significant advantage of using CNC multi-spindle machines is the boost in productivity. By performing several tasks at once, manufacturers can complete large volumes of work in a fraction of the time it would take with single-spindle machines. In industries where deadlines are tight, such as custom furniture manufacturing, multi-spindle CNC routers allow for rapid scaling of production without compromising on quality.

Superior Precision and Consistency

CNC multi-spindle machines provide superior precision, ensuring that each part or piece is identical to the next. This level of consistency is essential in woodworking, where even minor discrepancies can affect the final product. With multi-spindle CNC router spindles, woodworkers can produce uniform pieces with minimal human intervention, reducing the likelihood of errors and improving the overall quality of the work.

Benefits of Using CNC Multi-Spindle Machines

Reduced Labor Costs and Human Error

One of the main benefits of CNC multi-spindle machines is the reduction in labor costs. Since these machines can operate autonomously after programming, they minimize the need for skilled labor. Additionally, fewer hands-on operations mean a significant reduction in human error, which is especially important in projects requiring intricate designs or precision measurements. As a result, manufacturers can save both time and money while increasing production output.

Increased Productivity and Efficiency

Another major benefit of CNC multi-spindle machines is their ability to handle multiple tasks simultaneously. For instance, when working on a custom wooden piece, a multi-spindle machine can cut, carve, and drill at the same time, significantly reducing production time. This efficiency is particularly useful in industries like cabinetry or furniture production, where quick turnaround times are crucial.

Comparing Single and Multi-Spindle CNC Machines

Advantages of Multi-Spindle Over Single Spindle

When comparing single-spindle to multi-spindle CNC machines, the advantages of the latter become clear. While single-spindle machines excel in smaller projects and offer more control for intricate designs, multi-spindle machines shine in large-scale production. They are capable of performing complex operations faster, and in many cases, at a lower cost per unit. This makes them the preferred choice for businesses looking to scale operations or reduce production times without sacrificing quality.

Situations Where Multi-Spindle Machines Excel

Multi-spindle CNC machines are particularly beneficial in high-volume manufacturing environments. In woodworking, for example, multi-spindle CNC router spindles can be used to simultaneously craft multiple components of a piece of furniture, such as chair legs or table tops. The ability to work on several pieces at once is not only efficient but also ensures that each part is identical, which is essential for mass production.

Applications of CNC Multi-Spindle Machines in Woodworking

Crafting Complex Wooden Pieces

Woodworkers can greatly benefit from the precision and speed of CNC multi-spindle machines when crafting complex wooden pieces. These machines are ideal for projects such as intricate carvings, furniture components, or decorative woodwork. By programming the machine to execute precise cuts, craftsmen can ensure that their designs are perfectly replicated on each part, eliminating variations caused by manual labor.

Optimizing Production for Furniture Manufacturing

For furniture manufacturers, CNC multi-spindle machines are a game-changer. They enable the rapid production of identical components such as legs, frames, and panels, drastically cutting down production time. A multi spindle CNC machine can also switch between different tools quickly, allowing manufacturers to handle various tasks like cutting, drilling, and finishing in one continuous operation.

Selecting the Right CNC Multi-Spindle Machine for Your Woodworking Projects

Factors to Consider When Choosing a Machine

When selecting a CNC multi-spindle machine for woodworking, it’s important to consider factors such as spindle speed, tool diameter, and the complexity of the projects you’ll be working on. Machines with adjustable spindle speeds are ideal for woodworking, as different materials require different cutting speeds to achieve the best results. Additionally, the type of spindle—whether air-cooled or water-cooled—can affect the machine’s performance and longevity.

Recommended Models for Different Woodworking Needs

For beginners or small shops, a CNC router spindle with three or four spindles may suffice for basic furniture production. However, larger manufacturing operations should consider investing in multi-spindle CNC router spindles with six or more spindles to handle high-volume production. It’s also worth investing in a machine with robust software that can easily handle intricate designs and detailed programming for complex woodworking projects.

Conclusion

In conclusion, CNC multi-spindle machines offer a host of benefits for woodworking and other industries. From enhanced productivity and precision to reduced labor costs and errors, these machines are an essential tool for manufacturers looking to streamline operations and increase output. Whether you’re producing custom furniture or large-scale wooden structures, a multi-spindle CNC machine can significantly improve the efficiency and quality of your work.

In summary:

- CNC multi-spindle machines significantly increase productivity by allowing for simultaneous machining of multiple parts.

- They offer superior precision, ensuring consistent quality across all produced components.

- Using CNC multi-spindle machines reduces labor costs by minimizing the need for manual intervention.

- These machines are ideal for industries requiring high-volume production, such as woodworking and furniture manufacturing.

- Choosing the right CNC multi-spindle machine requires careful consideration of your specific production needs, including spindle speed and tool compatibility.

FAQs

What types of woodworking projects benefit most from CNC multi-spindle machines?

CNC multi-spindle machines are especially useful for high-volume projects such as furniture manufacturing, where multiple identical components need to be produced quickly and with precision.

What Makes CNC Multi-Spindle Machines Ideal for Woodworking?

The ability to simultaneously machine multiple parts and ensure consistent quality makes CNC multi-spindle machines ideal for woodworking projects, particularly those requiring detailed carvings or repetitive components.

How Do CNC Multi-Spindle Machines Improve Production Times?

By operating several spindles at once, these machines can complete tasks in a fraction of the time it would take a single-spindle machine. This makes them perfect for manufacturers aiming to boost productivity and meet tight deadlines.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.